Full-automatic contact lens cleaning device

A technology for cleaning devices and contact lenses, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. The effect of disassembly and replacement, avoiding the accumulation of residues, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

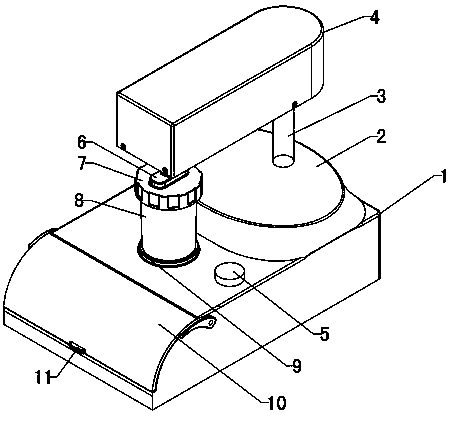

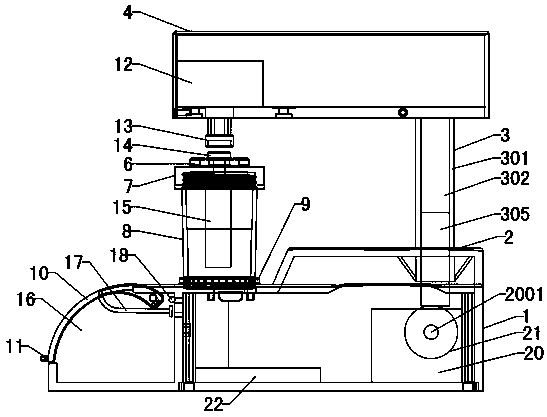

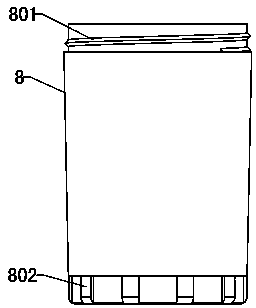

[0033] Refer to attached Figure 1~7: A fully automatic contact lens cleaning device, comprising a base 1, a lens rotating power device, a lifting and rotating device and a cleaning device, a vertical cleaning device is installed on one side of the top of the base 1, and a mesh lens box for rotating installation is arranged in the cleaning device 15. An elevating and rotating device is installed on the other side of the top of the base 1. The upper part of the elevating and rotating device is the rotating output end, which is fixedly connected to one end of the horizontally arranged lens rotating power device, and the other end of the lens rotating power device is the power output end. The power output end is connected to the top of the mesh lens box 15 through a transmission mechanism, and the base 1 is provided with a switch button 5 for controlling the lens rotation power device and the start and stop of the lifting and rotating device.

[0034] The lens rotation power devi...

Embodiment 2

[0042] The transmission mechanism is a gear transmission mechanism. The upper meshing part 13 and the lower meshing part 14 are a pair of bevel gears meshed with each other. toothed bevel gear. Other settings and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com