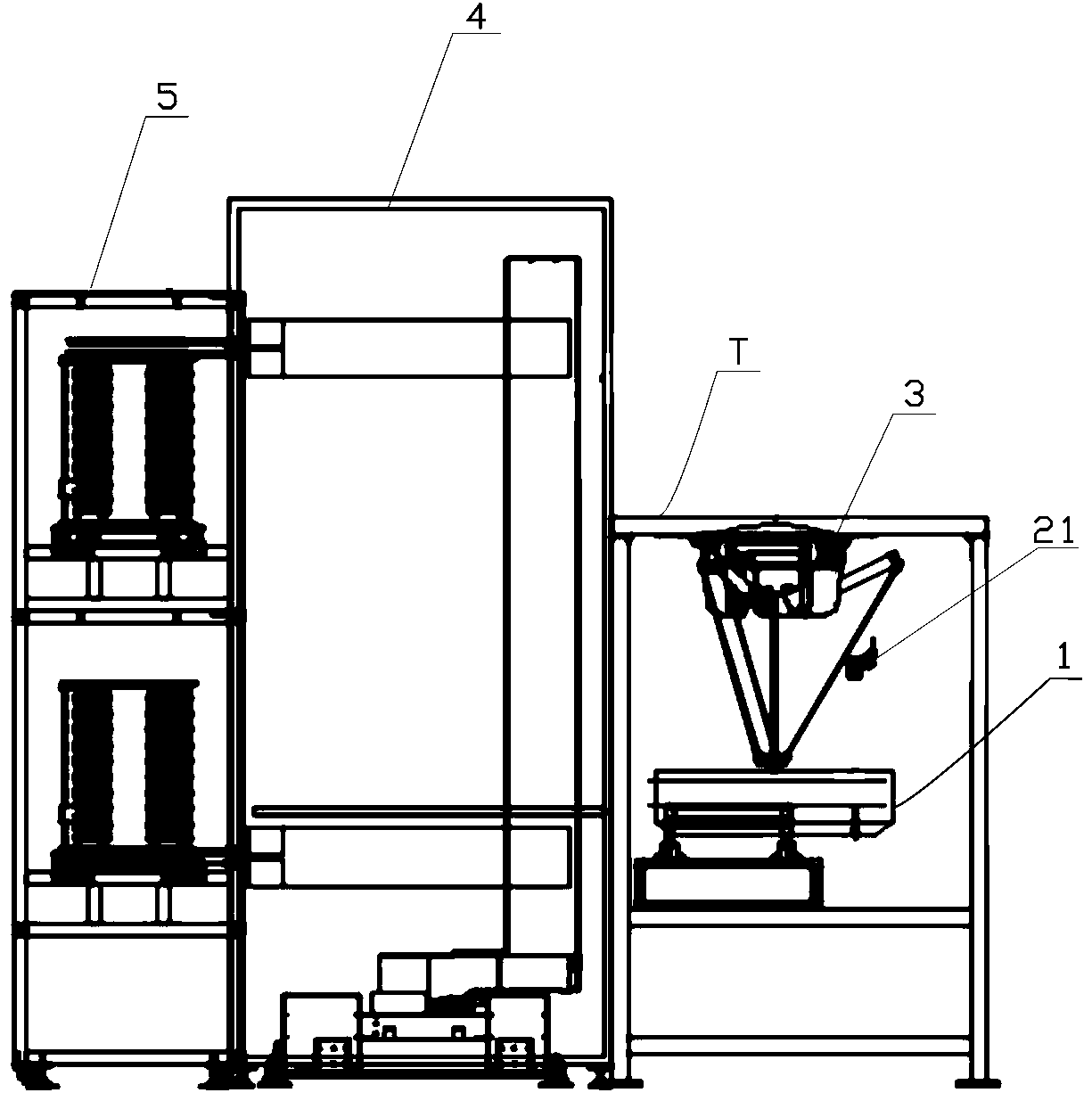

Panel sorting and shifting device

A transfer device and panel technology, applied in the direction of sorting, etc., can solve the problems of unautomated, low degree of automation, and high labor costs in the back-end handling, and achieve the effect of improving the demand for automated handling, reasonable structure, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0028] In other embodiments, the specifications of the panel storage positions on the grade buffer frame 1 can be adjusted, as long as the grade buffer frame 1 is set to be multi-layered, and the number of each layer corresponding to each column corresponds to the panels of the same specification. . In this embodiment, the hierarchical buffer rack 1 is set as a multi-column storage structure with at least two layers, which can save storage space.

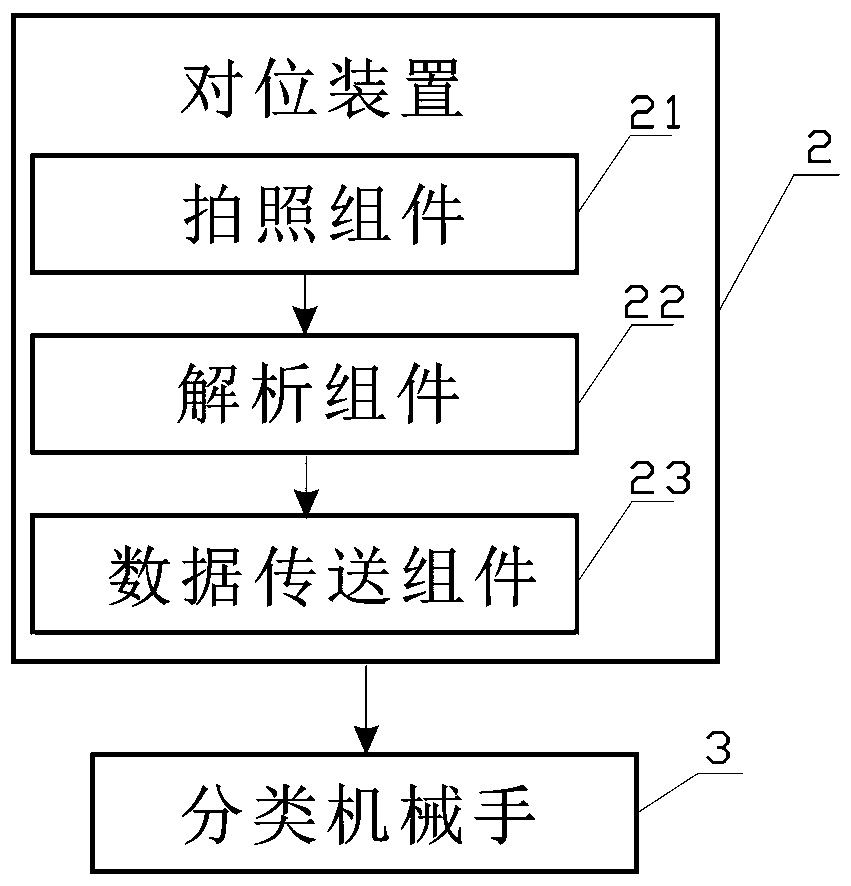

[0029] Further, such as figure 2 As shown, the alignment device 2 includes: a photographing component 21 for positioning and photographing the panels on the panel moving production line; and an analysis component 22 for analyzing the data according to the data captured by the photographing component 21 to obtain the panel position deviation ; In order to send the data analyzed by the analysis component 22 to the data transmission component 23 of the classification manipulator 3, wherein: the photographing component 21, the analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com