Printing roller coding device

A plate roller and bottom plate technology, applied in the direction of typewriter, printing, etc., can solve the problems of time-consuming, code misalignment, time-consuming and laborious, etc., and achieve the effect of simple implementation, simple operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

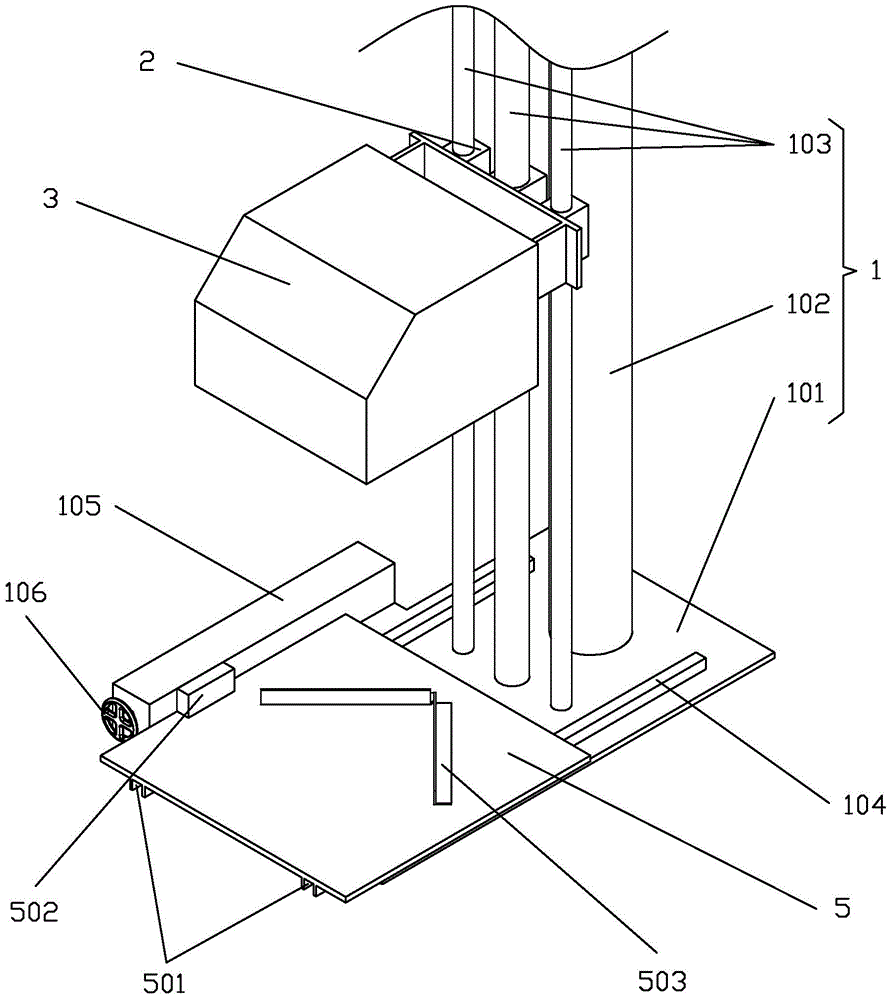

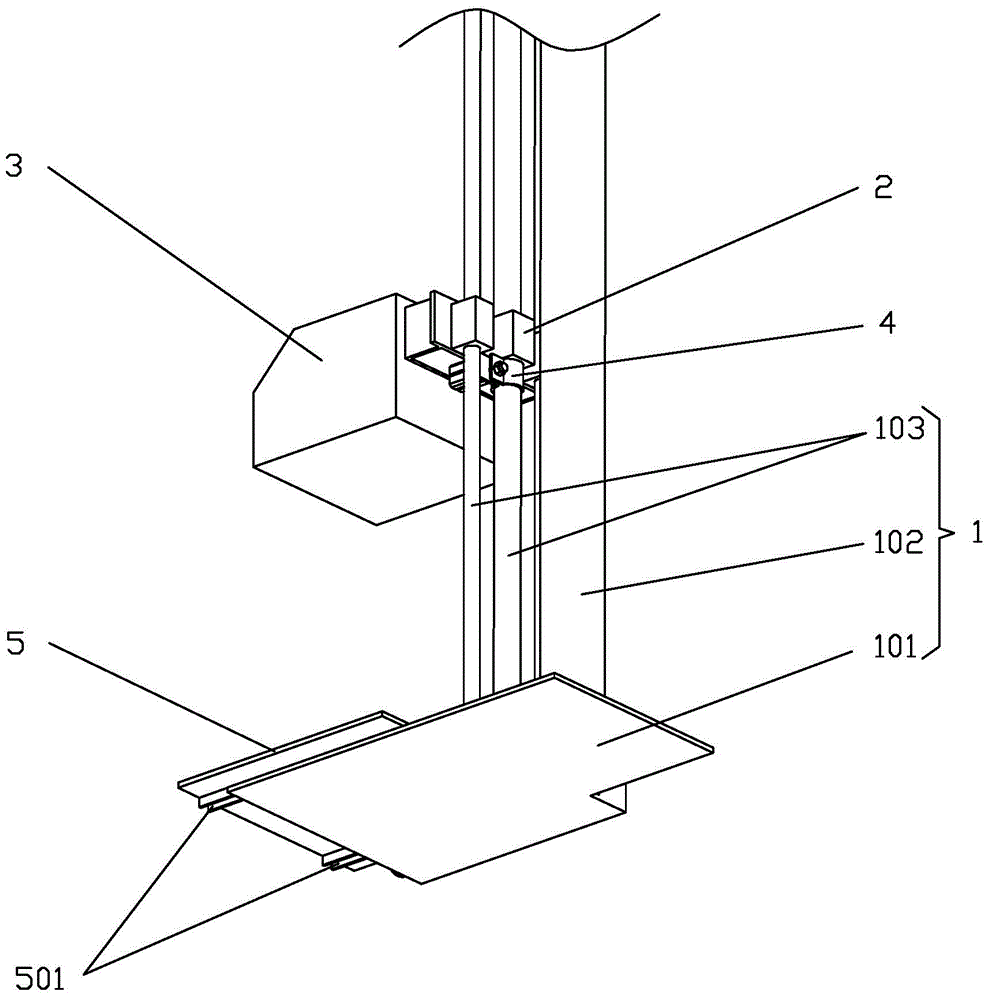

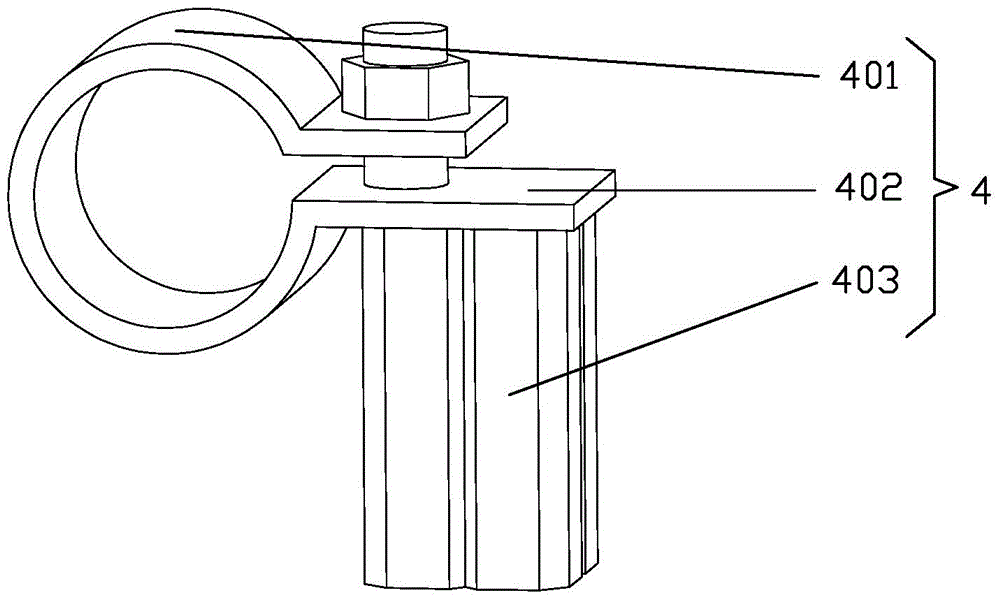

[0016] refer to Figure 1~Figure 4 , a version roller coding device, including a frame 1, the frame 1 includes a bottom plate 101 and a support rod 102 vertically arranged on the bottom plate 101, a guide rod 103, the guide rod 103 is equipped with a The magnetic force cylinder 2, the magnetic force cylinder 2 is connected with a coding machine 3, the locking mechanism 4 located at the lower side of the magnetic force cylinder 2 is installed on the guide rod 103, and the locking mechanism 4 includes a The rod 103 is fitted with an annular plate 401, a gap is reserved between the two ends of the annular plate 401, the two ends of the annular plate 401 extend outward to form a mounting plate 402, one of the mounting plates 402 is connected to a cylinder 403, The piston rod of the air cylinder 403 passes through the two mounting plates 402 and nuts are installed at the ends, and the bottom plate 101 is connected with an adjustment plate 5 for adjusting the position of the plate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com