Hub oil seal press fitting production line

A press-fitting production line and wheel hub technology, applied in the field of oil seal press-fitting, can solve the problems of time-consuming, labor-intensive, low-efficiency, damaged oil seals, etc., and achieve the effect of reducing damage, improving production efficiency, and realizing semi-automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

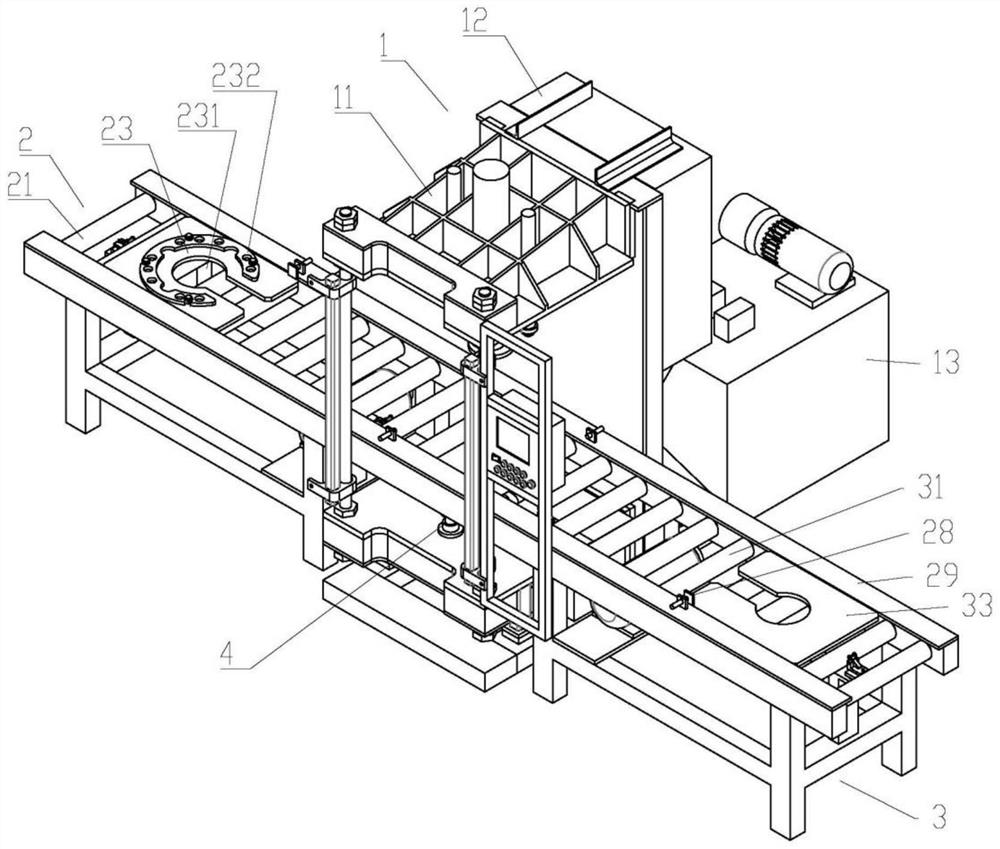

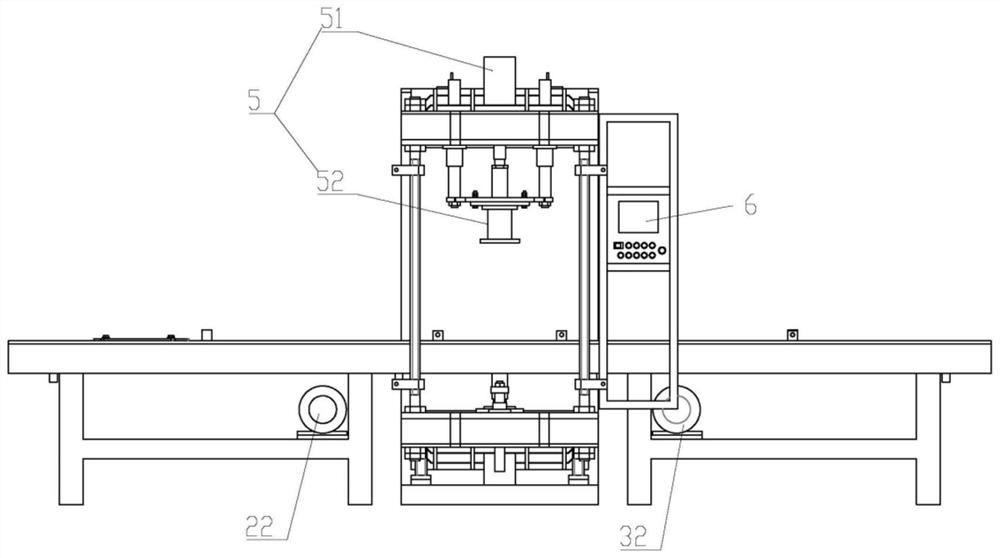

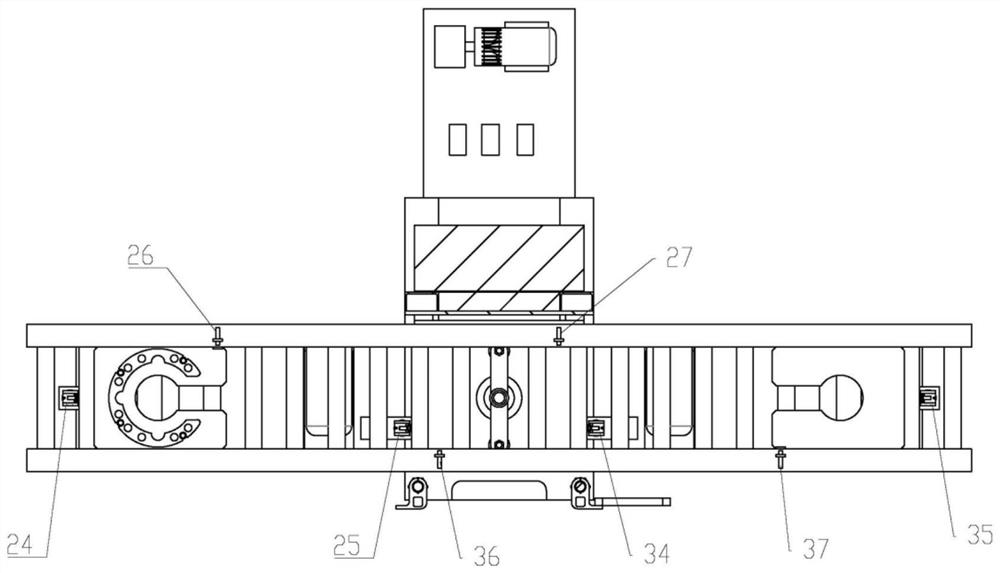

[0027] like Figure 1-5 As shown, the hub oil seal press-fitting production line of this embodiment includes a press-fitting machine 1, a feeding mechanism 2 for transferring materials to the press-fitting machine 1, and a feeding mechanism 3 for unloading materials from the press-fitting machine 1, The press-fitting machine 1 includes a "匚"-shaped frame 11, an electric control box 12 and a hydraulic station 13, and the frame 11 is provided with a supporting mechanism 4 for lifting the hub up and a pressing mechanism for pressing the oil seal into the hub 5; the feeding mechanism 2 includes a feeding roller 21, a feeding motor 22 that drives the rotation of the feeding roller 21, the feeding roller 21 is provided with a feeding tray 23, and the head and tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com