Bag-feeding-type vacuum packaging machine

A vacuum packaging machine and bag feeding technology, applied in the direction of packaging, packaging, transportation and packaging under vacuum/special atmosphere, can solve the problems of slow production speed, high labor intensity of workers, complex structure, etc., to improve production speed and structure. Simple and save the effect of manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

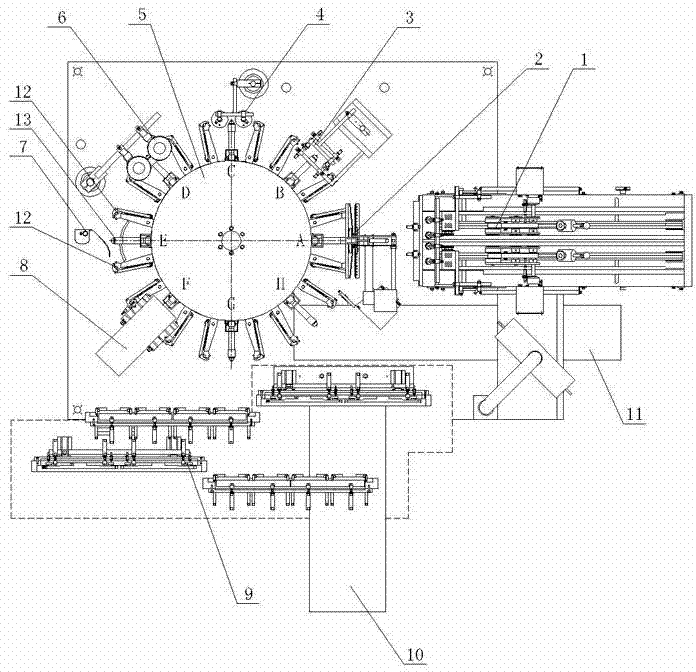

[0011] Such as figure 1 As shown, the bag-feeding vacuum packaging machine of the present invention includes a single turntable 5 arranged for indexing rotation on the workbench, and the outer circumference of the single turntable 5 is evenly equipped with a bag-up station A, a bag-opening station B, a support There are eight stations including bag station C, feeding station D, filling inspection station E, spot sealing station F, vacuum sealing station G and waste recycling station H, each station is equipped with a set of machine clamps For the clamping of packaging bags, in order to adapt to the synchronous conveying of double bags, each group of machine clamps is composed of a middle machine clamp 13 and two left and right machine clamps 12 . The bag loading device 2 is correspondingly installed at the bag loading station A, and the horizontal bag feeding mechanism 1 is provided on the outside of the bag loading device 2, the bag opening device 3 is correspondingly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com