Welding, spin-leveling and end plate processing assembly line

An assembly line and end plate technology, which is applied in the field of processing equipment for mechanical parts, can solve the problems of large size of annular single piece, large labor consumption and heavy weight of annular single piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

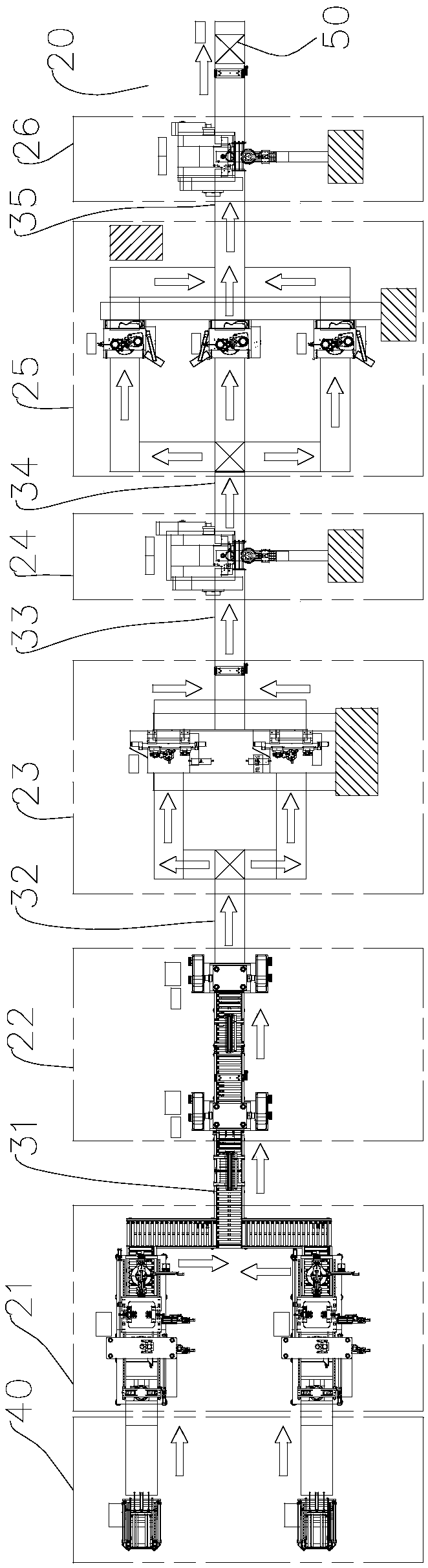

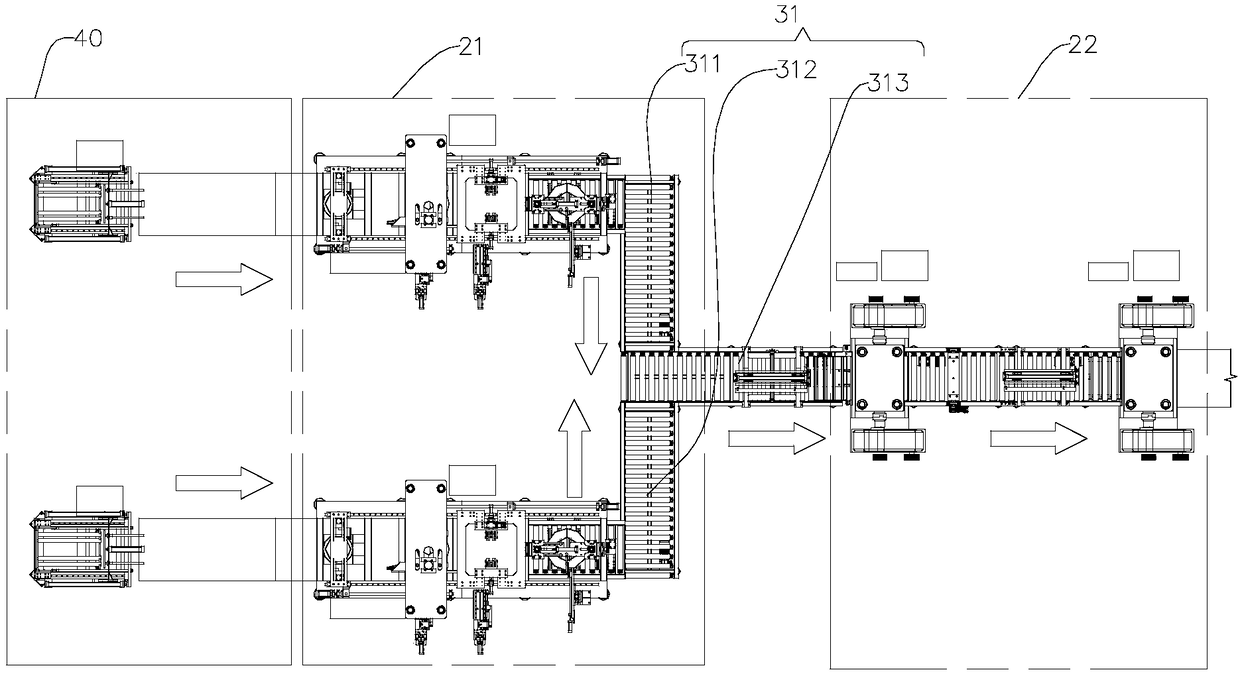

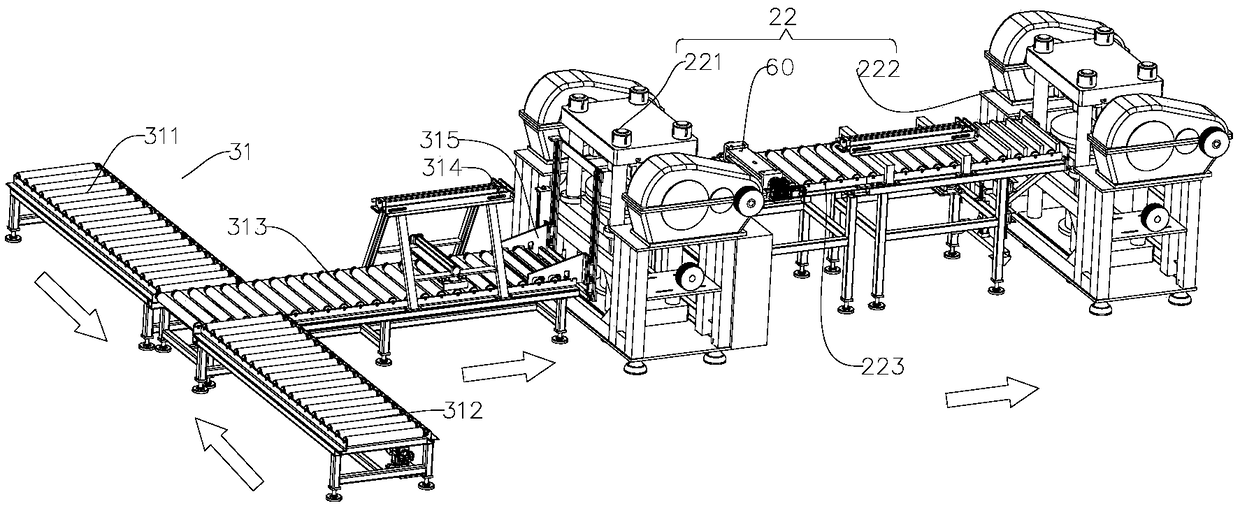

[0023] figure 1 A welding, flattening and end plate processing line 20 according to an embodiment of the present invention is schematically shown. The welding, flattening and end plate processing line 20 includes a welding unit 21, a flattening unit 22, a lathe unit 23, a first punching unit 24, a drilling and tapping unit 25, and a second punching unit 26, which are sequentially connected by a transport device 30 .

[0024] Among them, the welding unit 21 is used to weld the notch of the annular single piece shaped like a spring washer to form an end plate blank; the flattening unit 22 is used to flatten the end plate blank welded by the welding unit 21 to improve the end plate blank flatness; the lathe unit 23 is used to turn the outer diameter of the flattened end plate blank, so that the end plate and the pile hoop (also known as the skirt plate) can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com