Automatic paper feed digital cropping and creasing machine

An automatic paper feeding and creasing machine technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of high cost of die-cutting templates, low flexibility of use, and heavy manual work, etc., to achieve a solution Cutting accuracy and consistency of finished products, realize automation and intelligence, and achieve the effect of completeness and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

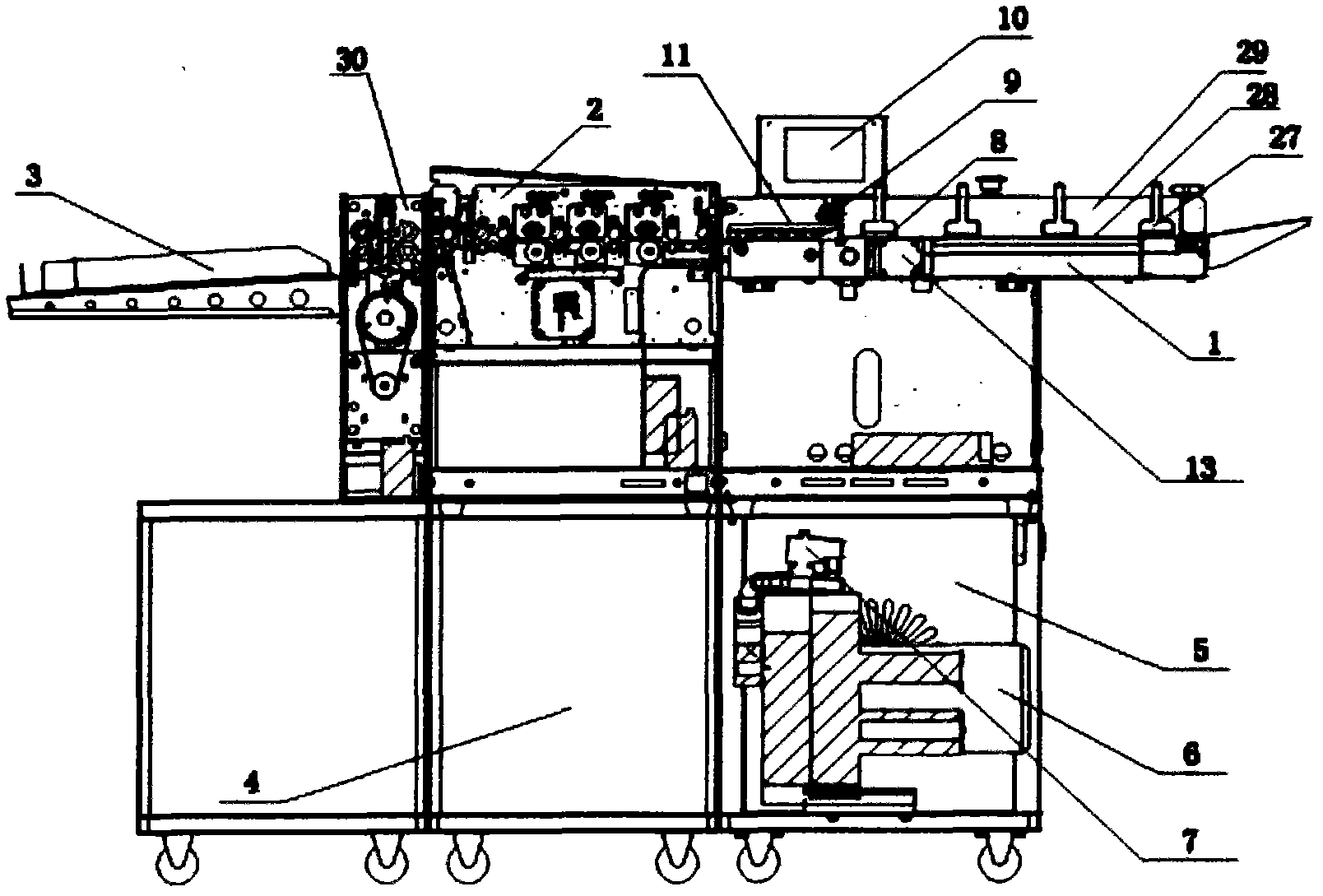

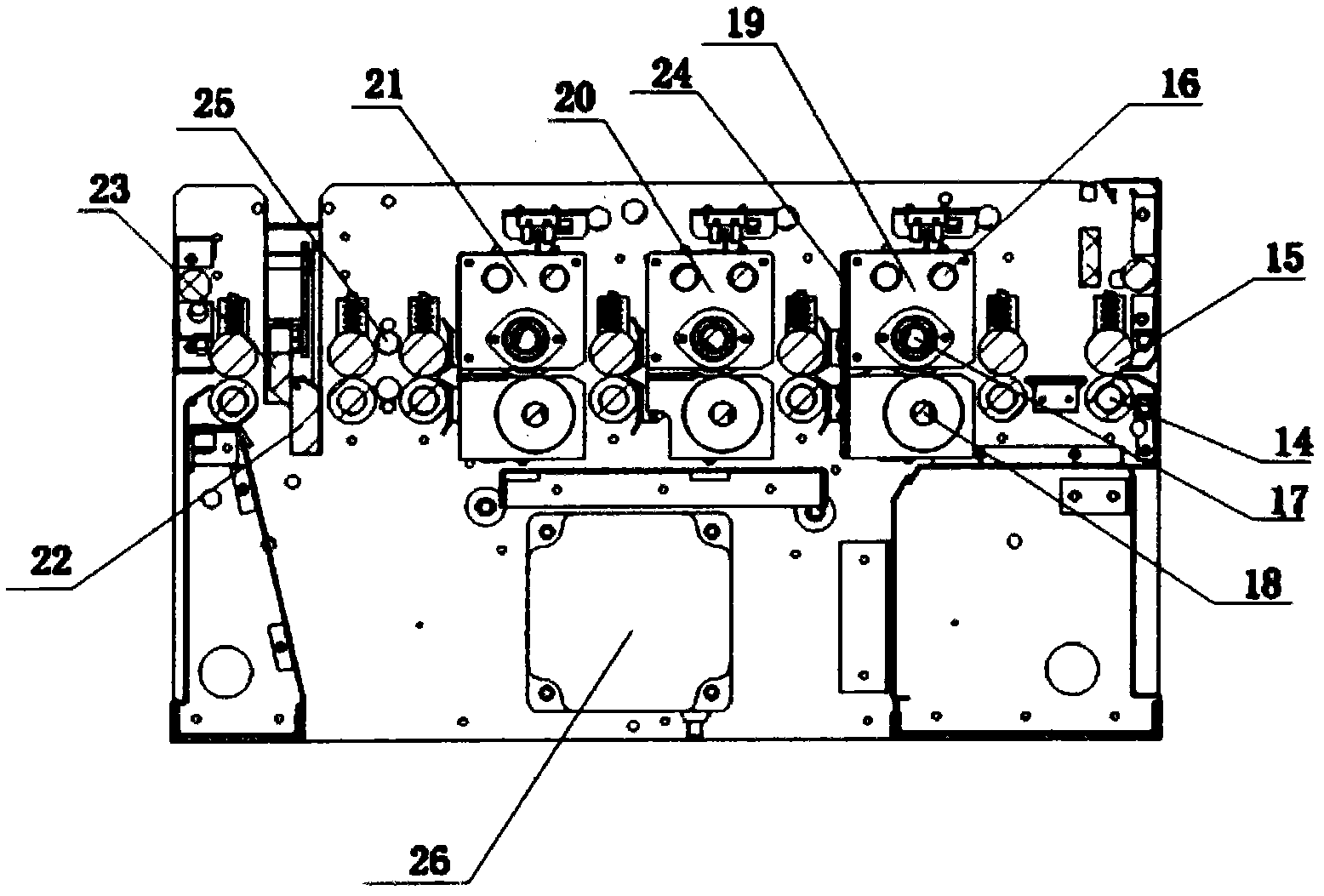

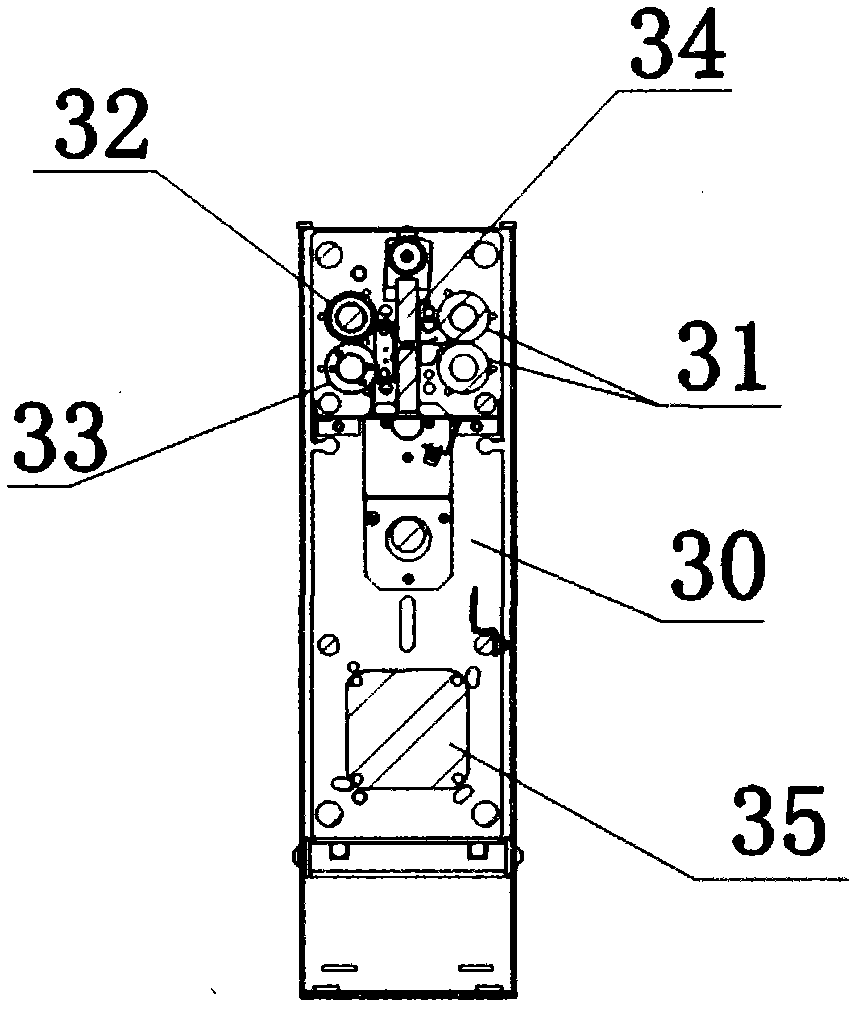

[0043] Example one: such as figure 1 , figure 2 , image 3 As shown, the paper feeding unit 1, the creasing unit 30, the cutting unit 2 and the paper delivery unit 3 are a modularly designed overall control structure or a series structure controlled independently of each other. Each module can be selected at will according to the needs in the work The modules can be combined or independently selected, and can also be combined as a whole. The order between the creasing unit 30 and the cutting unit 2 can also be selected at will.

[0044] The paper feeding unit 1 includes a suction wheel 8, a paper separation gauge mechanism 9, a correction channel 11, a wind deflector 27, a paper feeding table panel 28, a paper feeding drive motor 13, and a paper feeding table side plate 29. When the paper is stacked on the paper feeding When the table panel 28 is on, the negative pressure blowing provided by the fan unit 5 will be conveyed to the four air outlets of the side plate 29 of the paper...

Embodiment 2

[0050] Embodiment two: such as Figure 4 As shown, the main control board controls the vertical and horizontal cutting unit interface boards and drive boards. The vertical and horizontal cutting unit interface boards and drive boards are powered by a 5V power supply board. The 24V power board provides power to the horizontal cutting motor and 72V power supply. The board provides power to the paper feed motor, the cross-cutting knife position sensor, the slitting knife position sensor senses the vertical, the cross-cutting unit interface board, the drive board to drive the slitting knife motor and the slitting knife position motor, paper feed detection sensor and paper output The detection sensor induces the main control board to control and drive the feeding and feeding of the paper, and the motor is turned on / off through the safety switch.

Embodiment 3

[0051] Example three: such as Figure 5 As shown, the driver of the cutting unit 2 is first set by the timing module, and then enters the stepping motor control module. First, the equipment unit work detection module 6.1 is transferred to the equipment unit work detection module 6.2, and the slitting knife position motor control module is controlled at the same time Carrying out, the slitting knife motor control module performs the cutting work and the cross-cutting motor control module cutting work, and controls the paper conveying motor control module. The equipment unit work detection module 6.2 controls the cutting work of the cutting motor control module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com