Fabricated feather type suspended ceiling system and construction method thereof

A ceiling and prefabricated technology, which is applied to ceilings, building components, buildings, etc., can solve the problems of poor fixing effect between suspenders and floors, and poor fixing effects between decorative panels and floors, so as to increase the number of fixed nodes and improve Fixed stability, enhanced effects of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

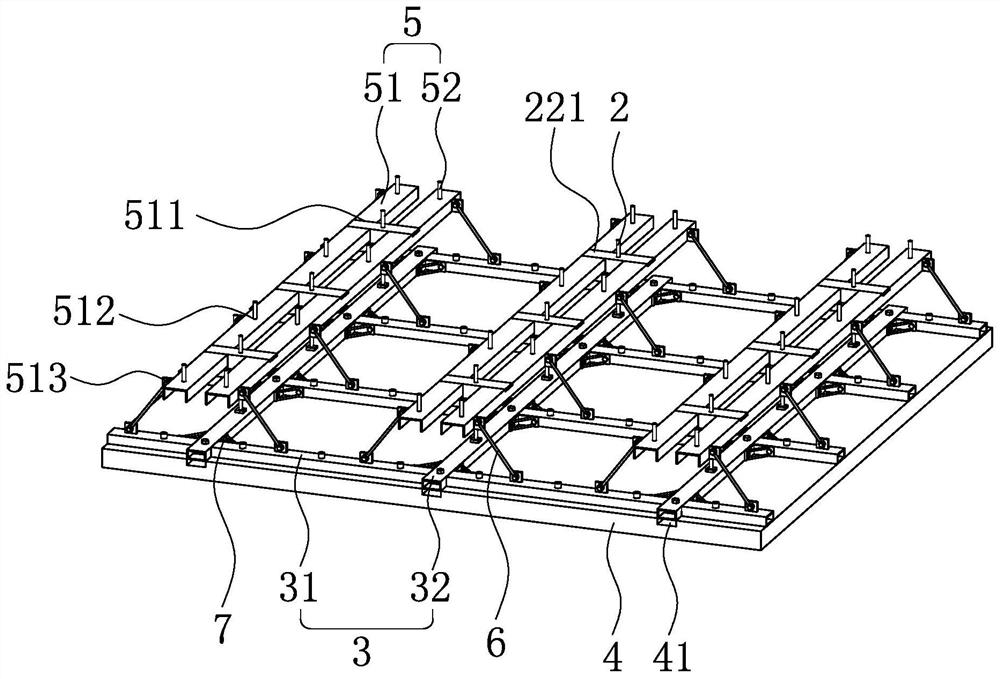

[0043] The following is attached Figure 1-4 The application is described in further detail.

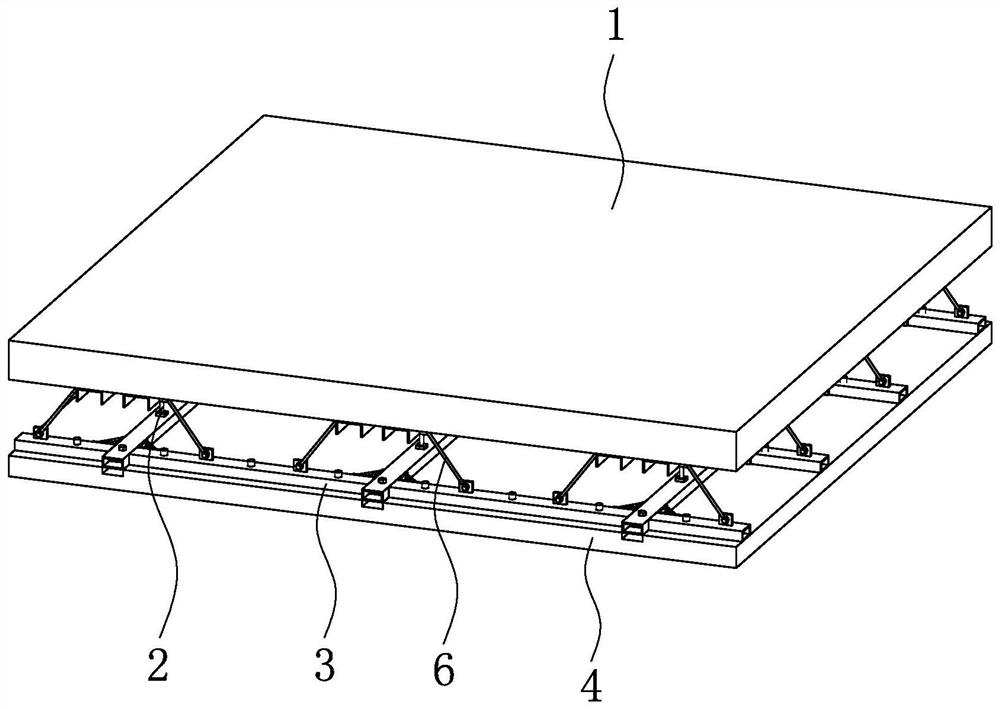

[0044] The embodiment of the present application discloses an assembled feather ceiling system. refer to figure 1 and figure 2 The prefabricated feather-type ceiling system includes a floor 1 , suspenders 2 arranged on the bottom of the floor 1 and evenly distributed in a net shape, a keel 3 connected to the bottom of the suspender 2 , and a decorative panel 4 fixed on the keel 3 .

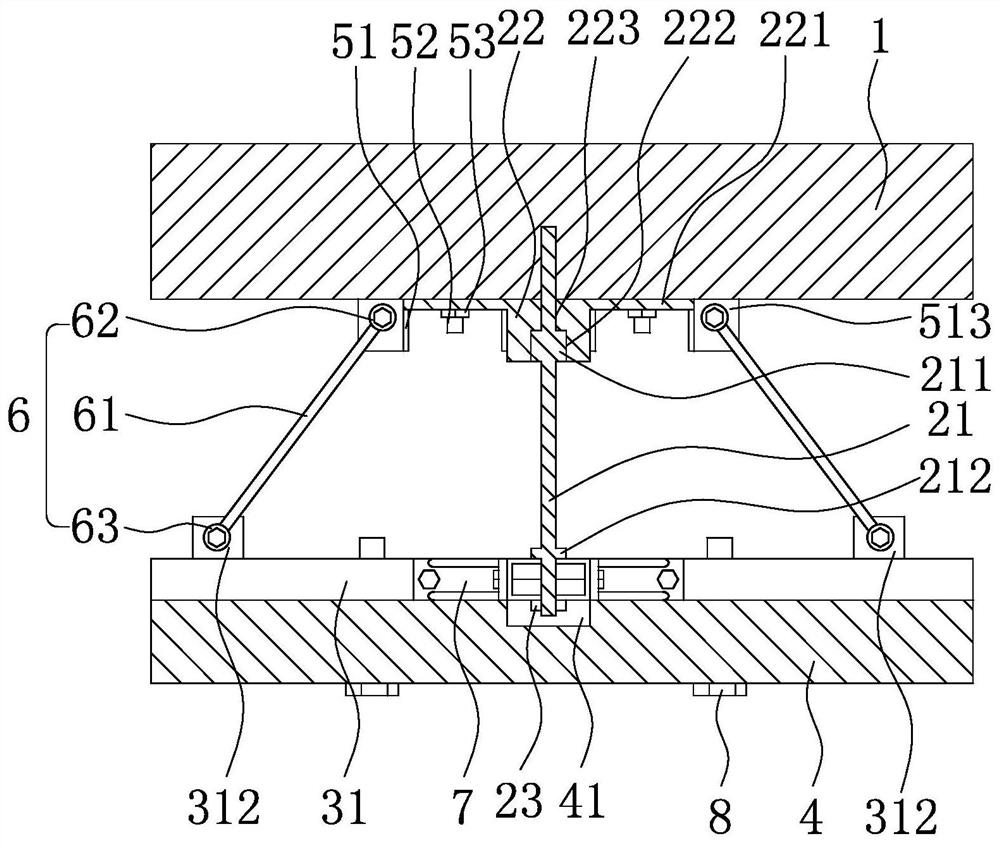

[0045] refer to figure 2 and image 3, the boom 2 is perpendicular to the bottom surface of the floor 1, the boom 2 includes a shaft body 21 and a fixed end 22, the upper part of the shaft body 21 is integrally formed with a limit stud 211, the bottom of the shaft body 21 is fixed with a limit platform 212, and the fixed end The top of the two opposite side walls of the head 22 is integrally formed with a wing plate 221 parallel to the bottom surface of the floor 1, and the middle position of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap