Multi-stage gear initial meshing air blowing device for intelligent production of electromechanical valve and method

An electromechanical valve and gear technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of unqualified detection, increased scrap rate and cost, incomplete meshing of gear sets, etc., to improve meshing accuracy and assembly degree, ensure structural integrity, good auxiliary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

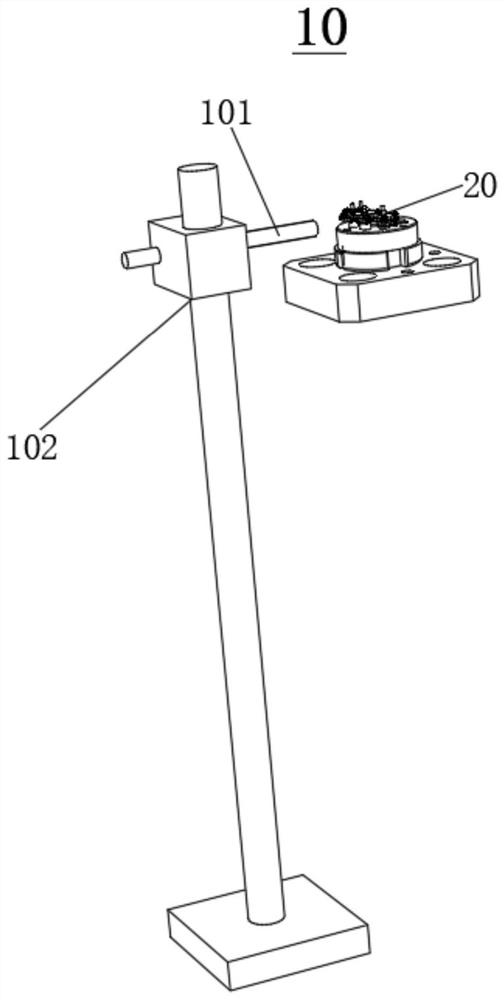

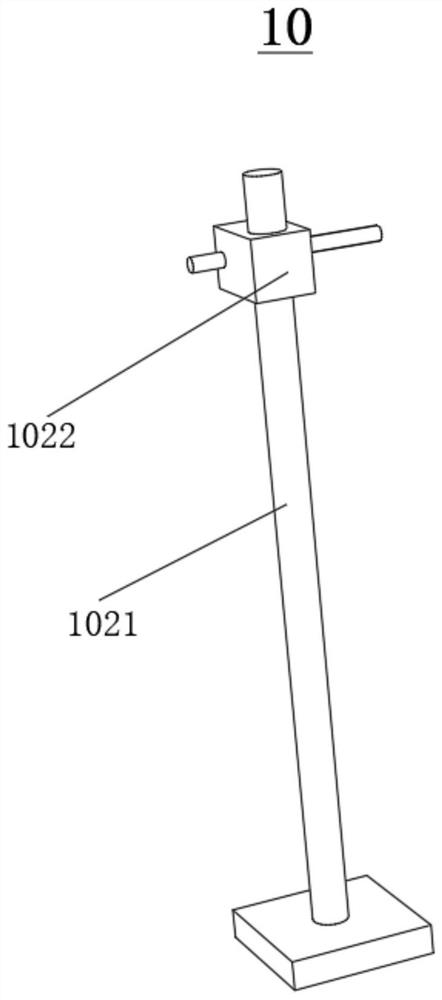

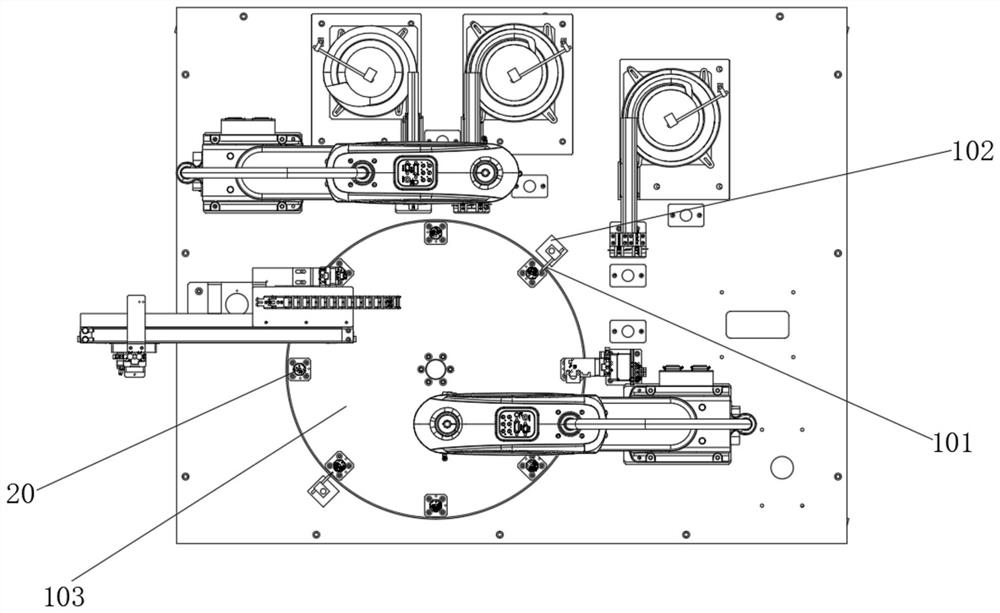

[0033] like figure 1 As shown, the first embodiment of the present invention discloses a multi-stage gear initial meshing air blowing device 10 for intelligent production of electromechanical valves, which at least includes an air blowing device 101 arranged after the installation process of the multi-stage gear 20 of the gearbox , the air blowing part 101 is used to continuously or intermittently blow air to generate an air flow directed to one or more gears in the multi-stage gear 20 of the gearbox, and the multi-stage gear 20 of the gearbox is driven to rotate and mesh based on the air flow.

[0034] The multi-stage gear initial meshing air blowing device 10 used for the intelligent production of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com