Cantilever frame used for setting up scaffold in prefabricated assembling structure and mounting method of cantilever frame

An installation method and prefabricated assembly technology, applied in the field of suspension frames, can solve the problems of increasing costs and labor, reducing structural quality, and inconvenient construction, so as to achieve the effect of protecting structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

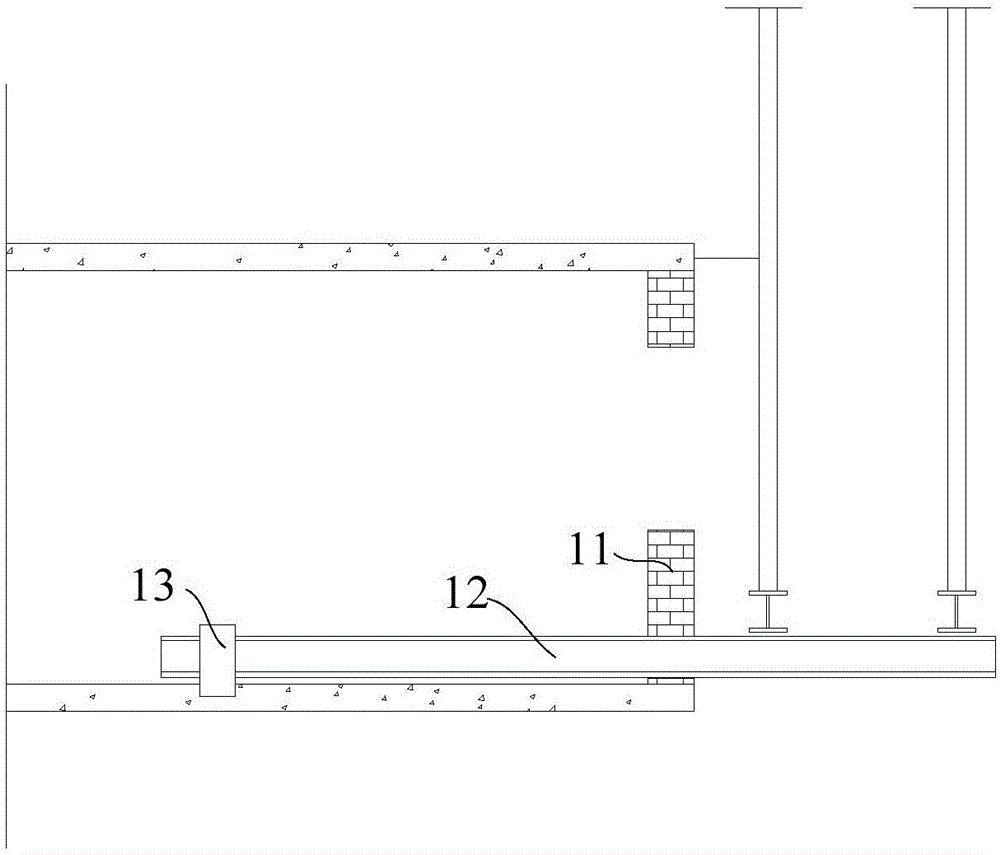

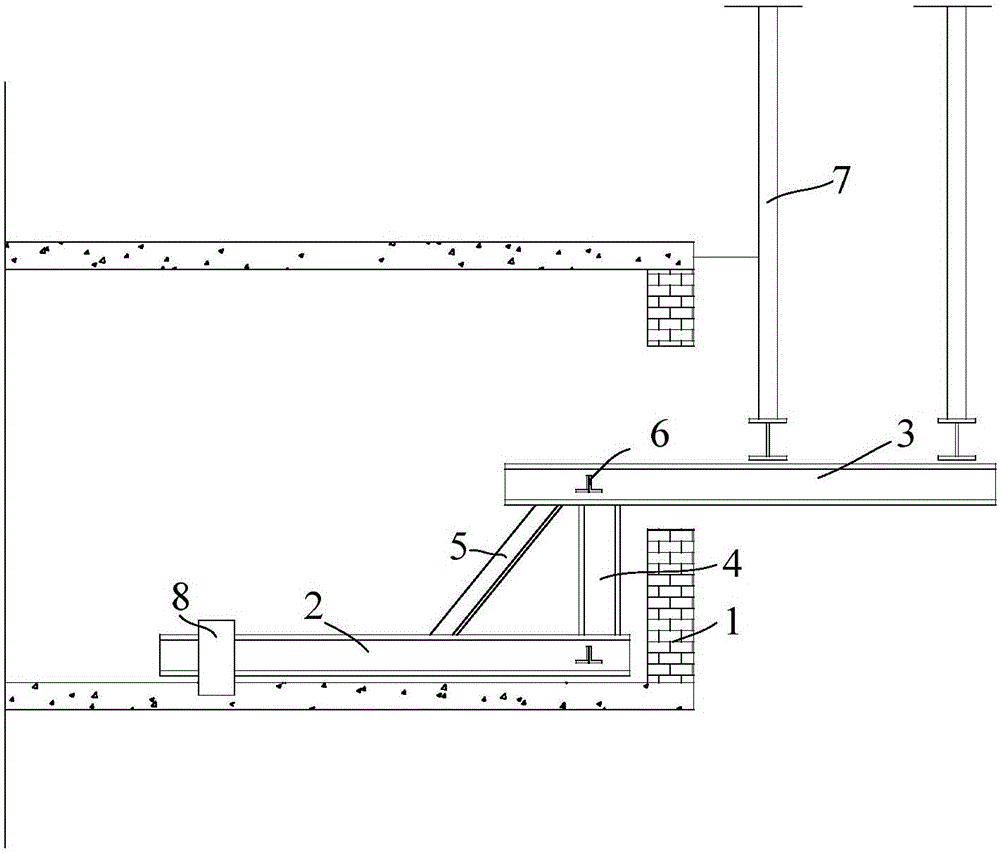

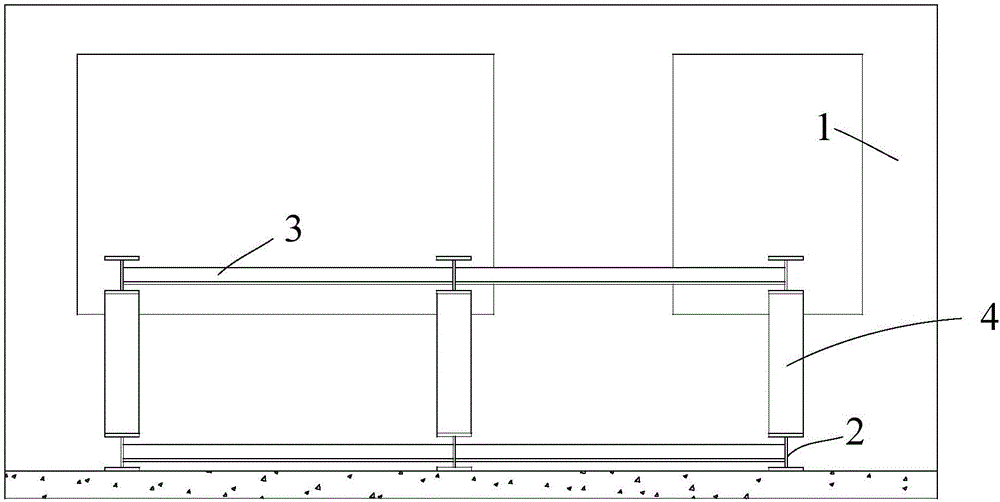

[0024] With the upgrading of the construction industry, considering the construction time, cost constraints and safety, for the construction of high-rise or super high-rise buildings, the application of cantilevered scaffolding is becoming more and more extensive. However, the traditional cantilevered scaffolding is to open holes on the building walls that have already been laid, such as figure 1 As shown, then extend the cantilever beams out of the building wall from the hole, fix a part of the cantilever beams located in the building wall to the floor with anchor rods, and finally place them on the cantilever beams extending out of the building wall Scaffolding is erected in prefabricated structures. However, this kind of scheme causes the structure of the building wall to be damaged, the structural strength is reduced, and it needs to be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com