Inclined hanging device of meat ripening cabinet and operation method thereof

An operation method and meat technology, which can be used in processed meat, hanging meat/sausage, slaughtering, etc., can solve the problems of difficulty in forming the micro-ecology of the flora, the weight of the finished product, and hindering the production of umami, so as to promote the balanced growth of microorganisms. , the same colony growth conditions, the effect of preventing the increase of water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

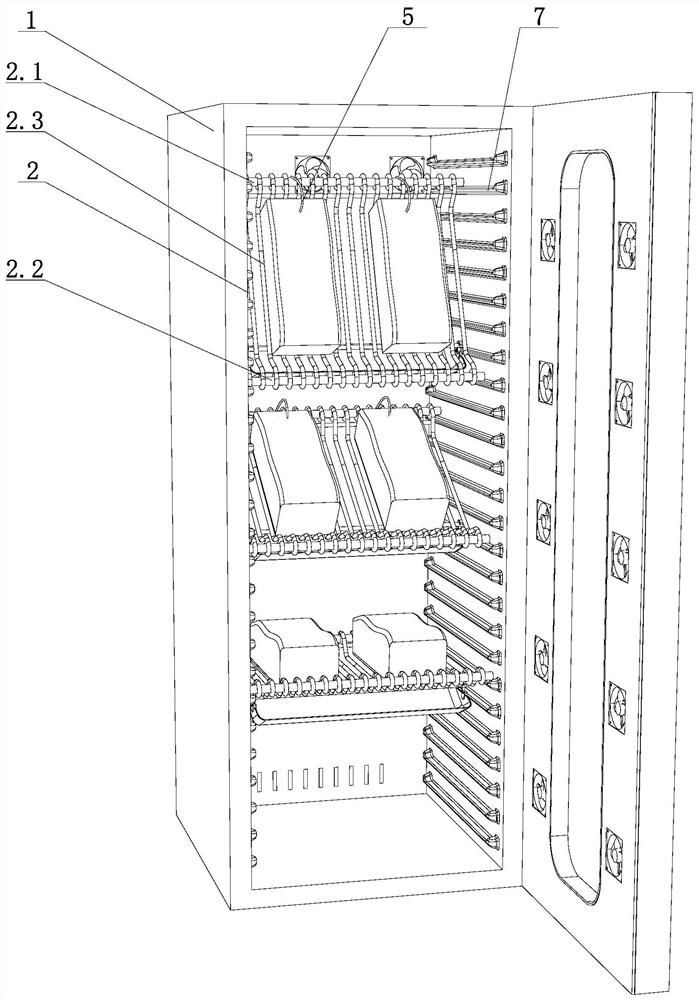

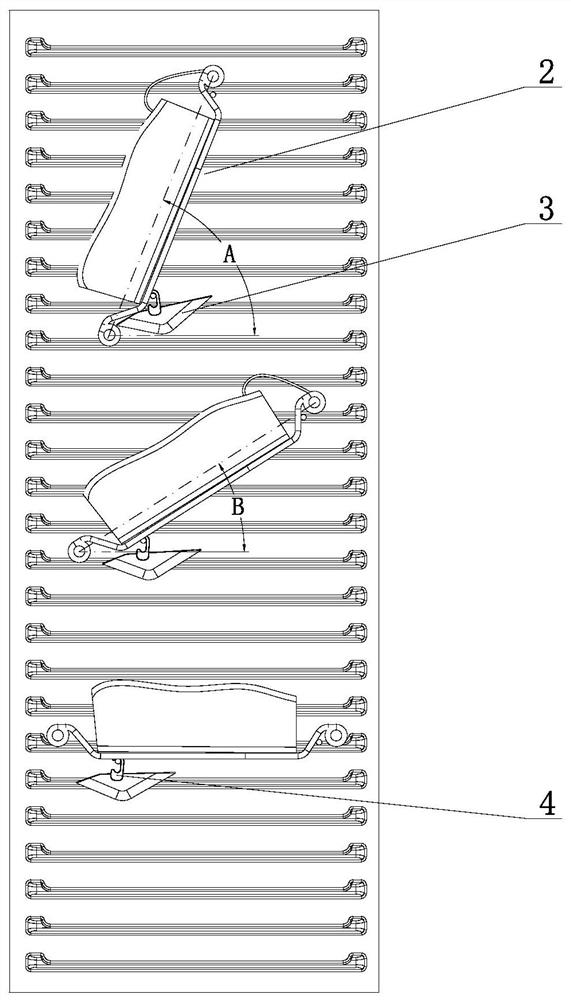

[0028] see Figure 1-2 , the oblique hanging device of the meat aging cabinet includes a cabinet body 1, a support frame 2 for fixing meat products, an adjustment mechanism for adjusting the inclination angle of the support frame 2 and a multi-layer bracket 7 are arranged in the cabinet body 1 , the support frame 2 is set on the bracket 7 through the adjustment mechanism.

[0029] In this embodiment, the support frame 2 is provided with hooks 5 or clips for fixing the meat; the brackets 7 are provided on the left and right inner walls of the cabinet 1 .

[0030] The oblique hanging device of the meat aging cabinet also includes a liquid collection box 3 for containing the exudate of meat products, the liquid collection box 3 is connected to the support frame 2 and the liquid collection box 3 is located on the inclined side of the support frame 2 below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com