Asphalt laying equipment for municipal engineering building

An engineering and construction technology, applied in the field of asphalt laying equipment, can solve the problems of asphalt scalding, time-consuming and laborious, and heavy linoleum rolls, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

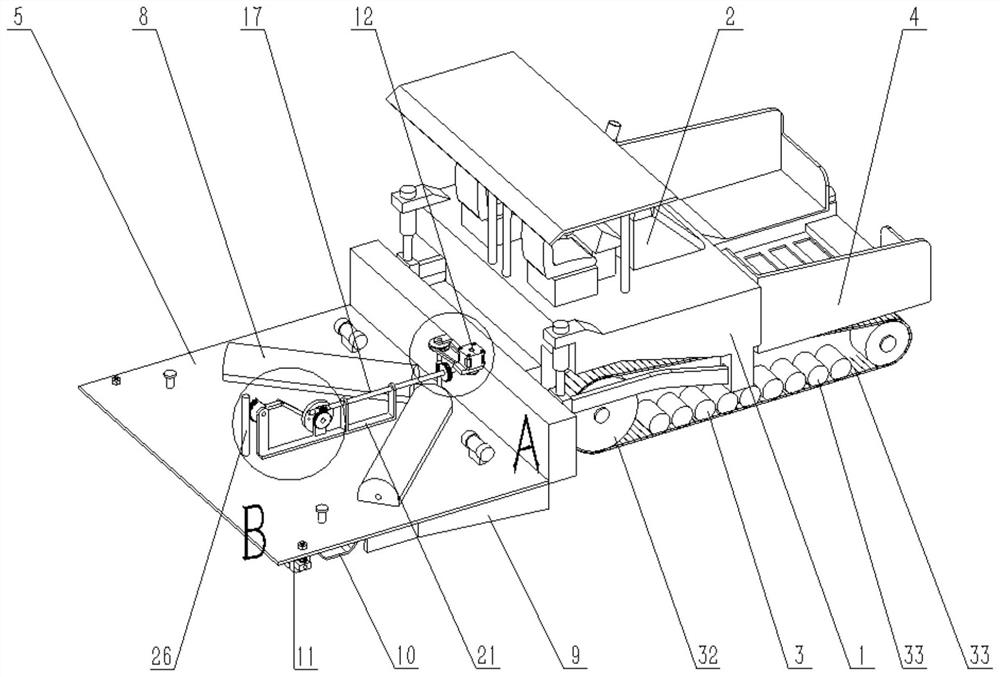

[0030] The asphalt laying equipment of a kind of municipal engineering building of the present invention is further described in conjunction with accompanying drawings, and the present invention is described in further detail below in conjunction with embodiment:

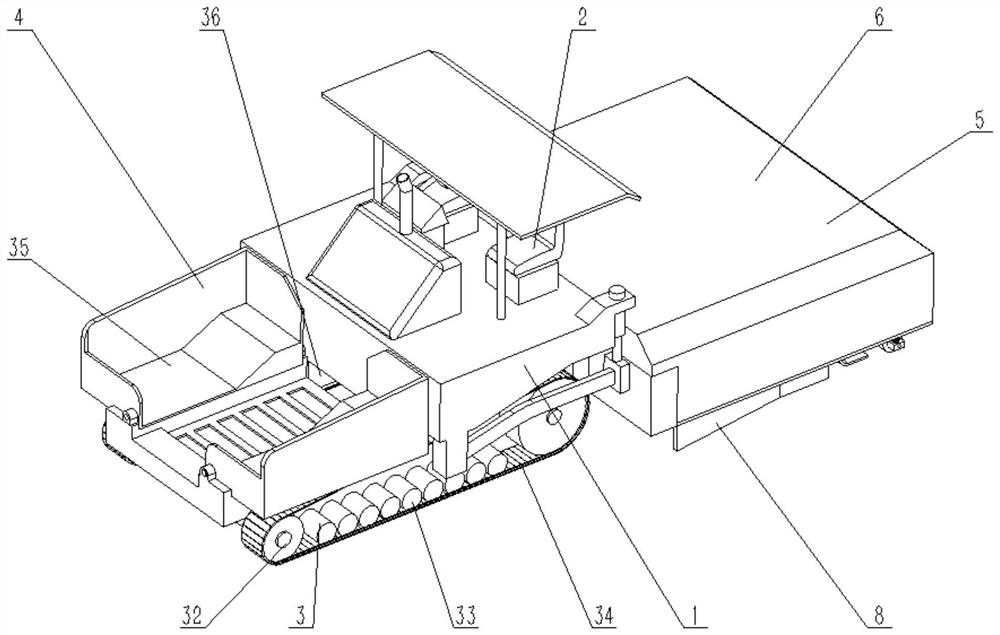

[0031] A kind of asphalt laying equipment for municipal engineering buildings, including a laying machine body 1, a control console 2 is arranged on the laying machine body 1, a drive device 3 for driving the laying machine body 1 is arranged below the console 2, and the control console 2 A feeding device 4 is arranged on the left side and above the driving device 3 , and a paving device 5 for paving asphalt is arranged on the right side of the console 2 .

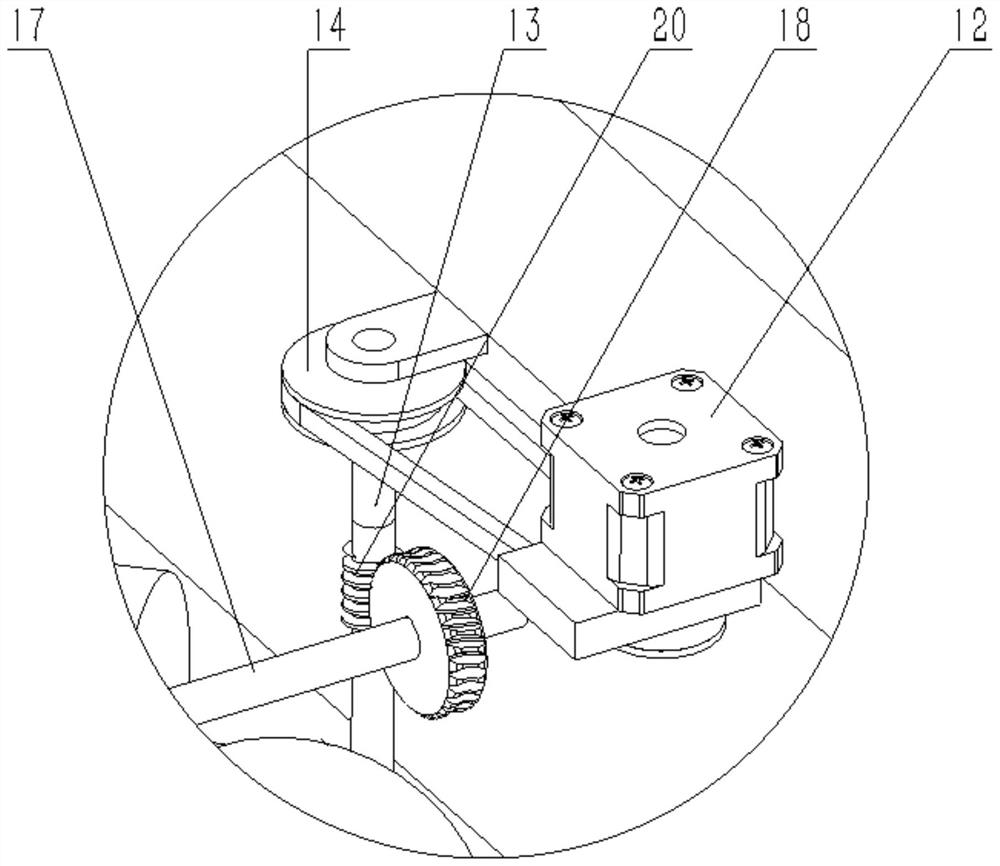

[0032] Further, the paving device 5 includes an organic casing 6, a pair of mutually perpendicular placing grooves are opened at the bottom of the casing 6, and a spiral paving roller 7 is rotatably arranged in each placing groove, and the outer side of the spira...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap