Display module and electronic terminal

A technology for displaying modules and modules, which is applied in the direction of identification devices and instruments, and can solve the problems of time-consuming and laborious module testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

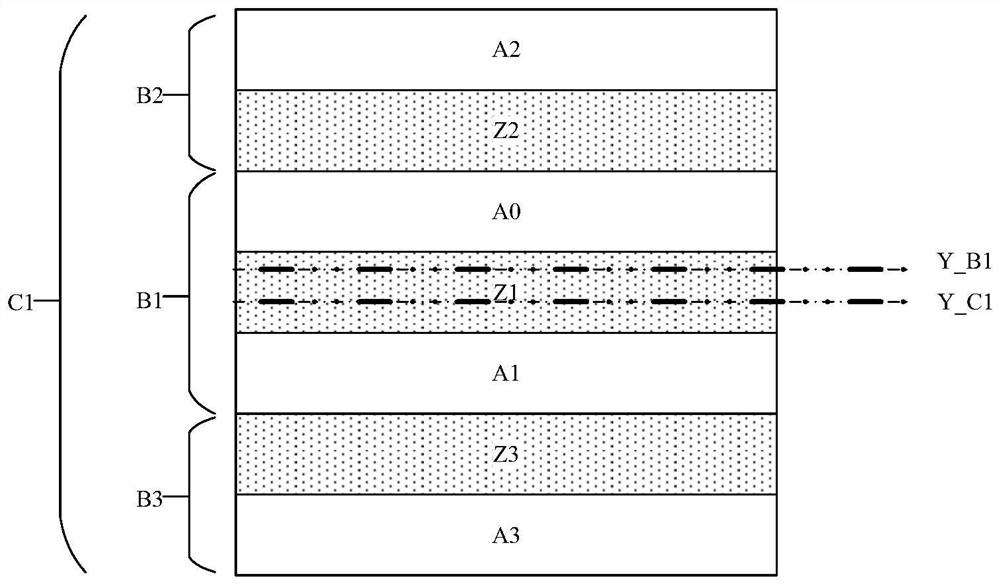

[0041] figure 1 Schematic diagram of the structure of the module provided for the embodiment of this application Figure 1 . Such as figure 1 As shown, the module 100 provided by the embodiment of the present application includes: a first sub-module (B1 in the figure), a second sub-module (B2 in the figure), and a third sub-module (B3 in the figure).

[0042] Wherein, the second sub-module and the third sub-module are respectively located on both sides of the first sub-module; the film layer in the first sub-module, the film layer in the second sub-module, the film layer in the third sub-module The film layers of the second sub-module and the third sub-module are set in parallel to each other; the composition parameters of the second sub-module and the third sub-module are used to make the stress neutral layer of the module 100 and the stress neutral layer of the first sub-module meet the position coincidence condition.

[0043] In the embodiment of this application, please...

Embodiment 2

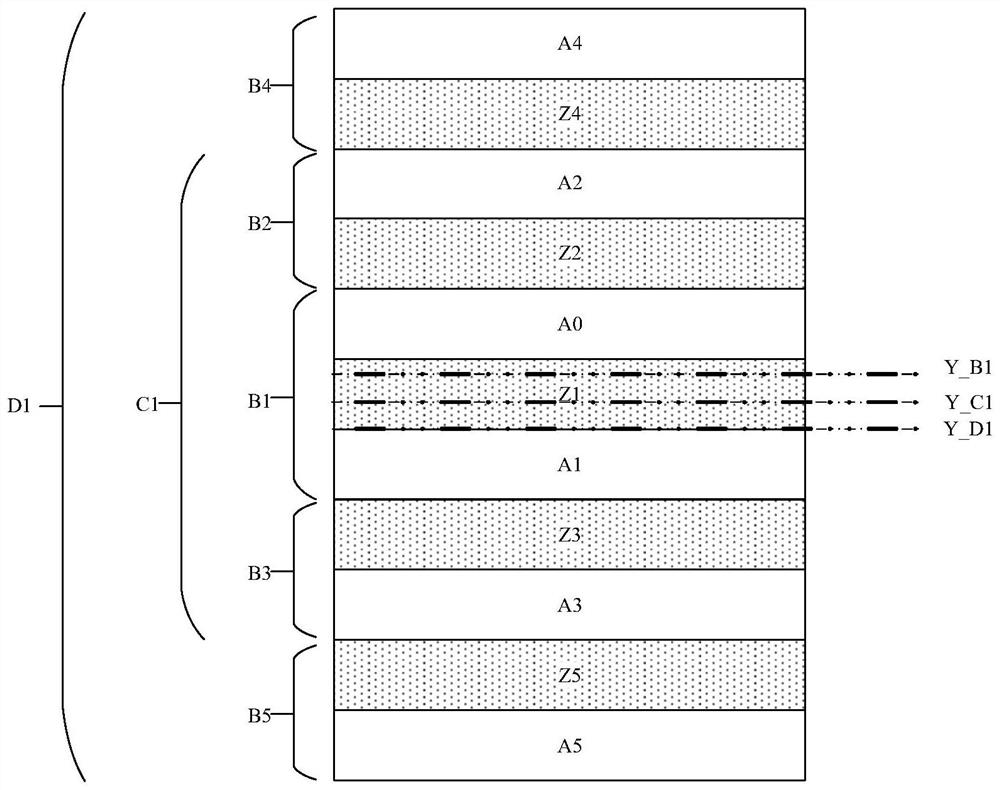

[0075] The embodiment of the present application also provides a module, which may include at least five sub-modules, the first sub-module, the second sub-module, the third sub-module, the fourth sub-module, and the fifth sub-module group, wherein each submodule may include at least one film layer. The composition parameters of the outermost submodule can be used to make the stress neutral layer of the whole module combined with the submodules of other submodules except the outermost submodule The position coincidence condition is reached.

[0076] In the embodiment of the present application, each film layer may be bonded by an adhesive layer. When the composition parameters of the film layer in the outermost submodule have been determined, the composition parameters of the adhesive layer in the outermost submodule can be set so that the stress neutral layer of the entire module is consistent with The stress-neutral layers of the sub-module combinations of the other sub-mod...

Embodiment 3

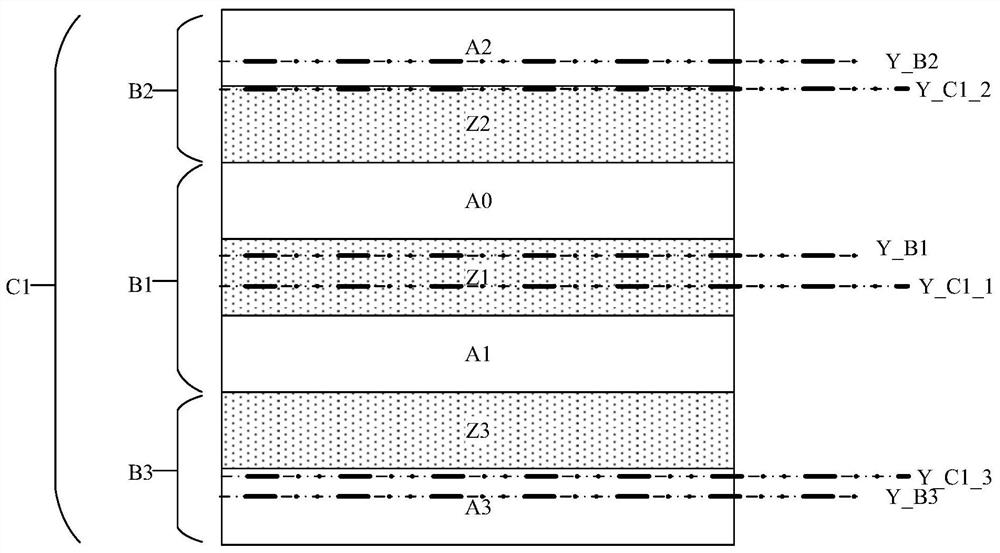

[0082] The embodiment of the present application also provides a module, which may include at least three sub-modules, for example, a first sub-module, a second sub-module and a third sub-module located on both sides of the first sub-module . Each sub-module respectively includes at least one film layer. The various film layers in the module can be bonded by an adhesive layer. Wherein, the number of stress-neutral layers of the module can be multiple.

[0083] In the embodiment of the present application, the number of stress-neutral layers of the module may be the same as the number of sub-modules in the module, or may be different from the number of sub-modules. When the number is the same, the stress-neutral layer of the module corresponds to the sub-module; when the number of the stress-neutral layer of the module is different from the number of sub-modules in the module, each stress neutral layer The neutral layer is respectively corresponding to at least one sub-modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com