Intelligent feeding and discharging full-detection machine

A technology of inspection machine and inspection box, which is applied in the field of full inspection machine, can solve problems such as product confusion, and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

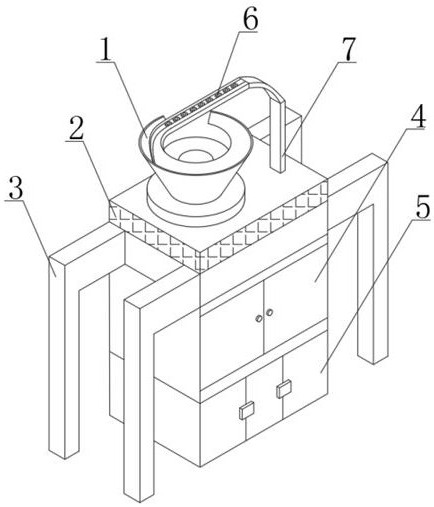

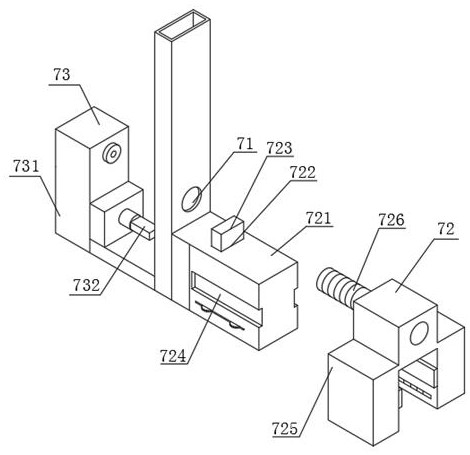

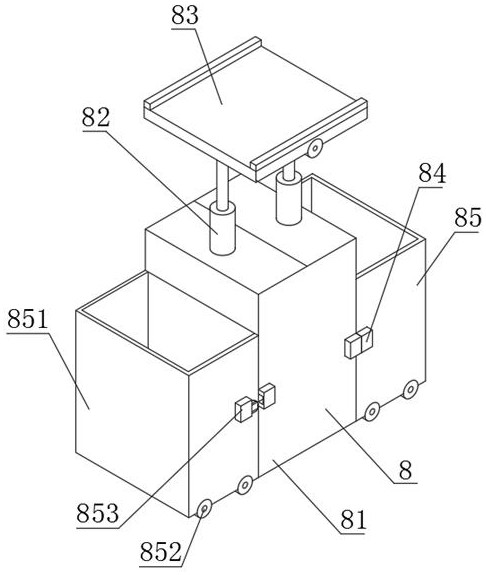

[0028] Refer to attached Figure 1-3 , an intelligent loading and unloading full inspection machine, including a vibrating plate 1, the bottom of the vibrating plate 1 is provided with a shock-absorbing interlayer 2, the two sides of the shock-absorbing interlayer 2 are connected to a support frame 3, and the bottom of the support frame 3 is A detection box 4 is provided, and the two sides of the bottom of the detection box 4 are detachably connected to the discharge device 85, the side of the vibrating plate 1 is connected to the discharge pipeline 6, and the discharge pipeline 6 is connected to the vertical slideway 7. Pass through the detection box 4 toward the slideway 7, the vibrating plate 1 sends the fastener to be detected into the discharge pipe 6, the width of the vertical slideway matches the fastener on the side to be inspected, and the fastener is in the discharge pipe 6 Pause, carry out quality inspection to it by the detection device in the detection box 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com