Six-axis robot pipeline package device

A six-axis robot and robot technology, applied in the field of line packs, can solve the problems of cross wear of line packs, achieve the effects of protecting cables, improving service life, and avoiding discounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] According to a specific embodiment of the present invention, the six-axis robot wire pack device of the present invention will be described in detail below.

[0054] The invention provides a six-axis robot pipeline package device, comprising:

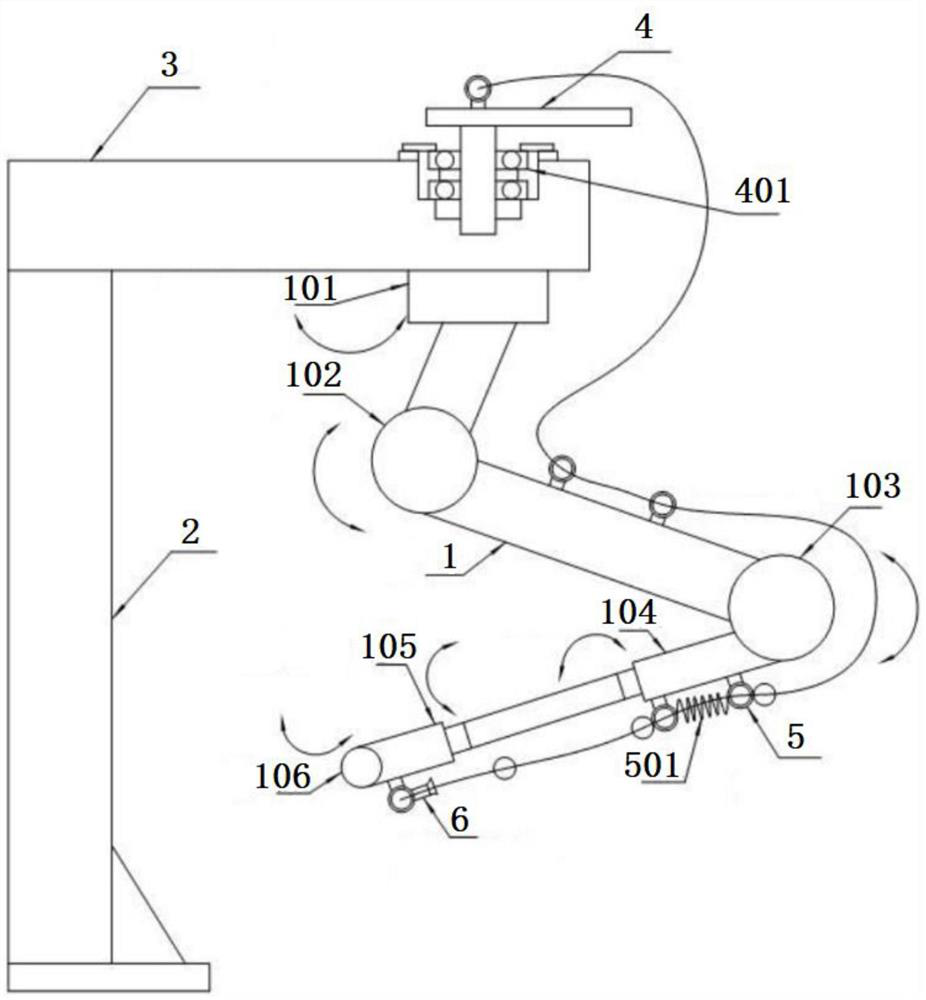

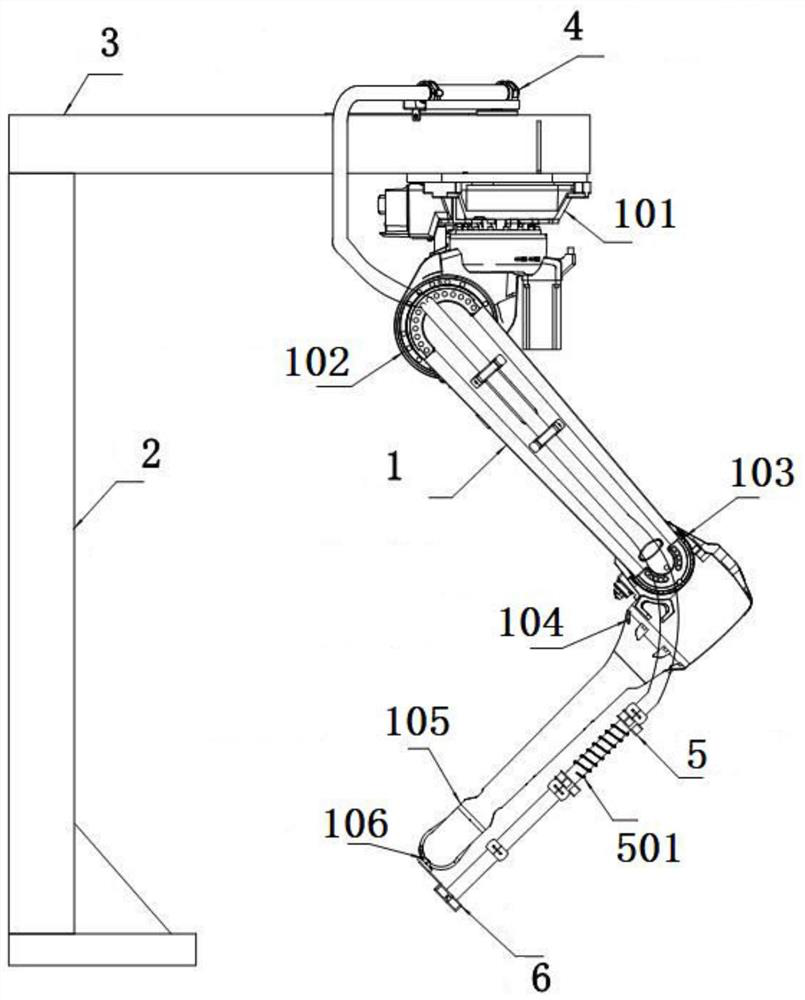

[0055] The pipeline package device, the six-axis robot 1 and the robot mount 3, the six-axis robot 1 includes six robot axes and the mechanical arm, and the six robot axes are the first axis 101 of the robot, the second axis 102 of the robot, the third axis 103 of the robot, and the fourth axis of the robot Axis 104, robot five-axis 105 and robot six-axis 106;

[0056] Robot one axis 101 is connected with robot two axis 102; robot three axis 103, robot four axis 104, robot five axis 105 and robot six axis 106 are connected sequentially;

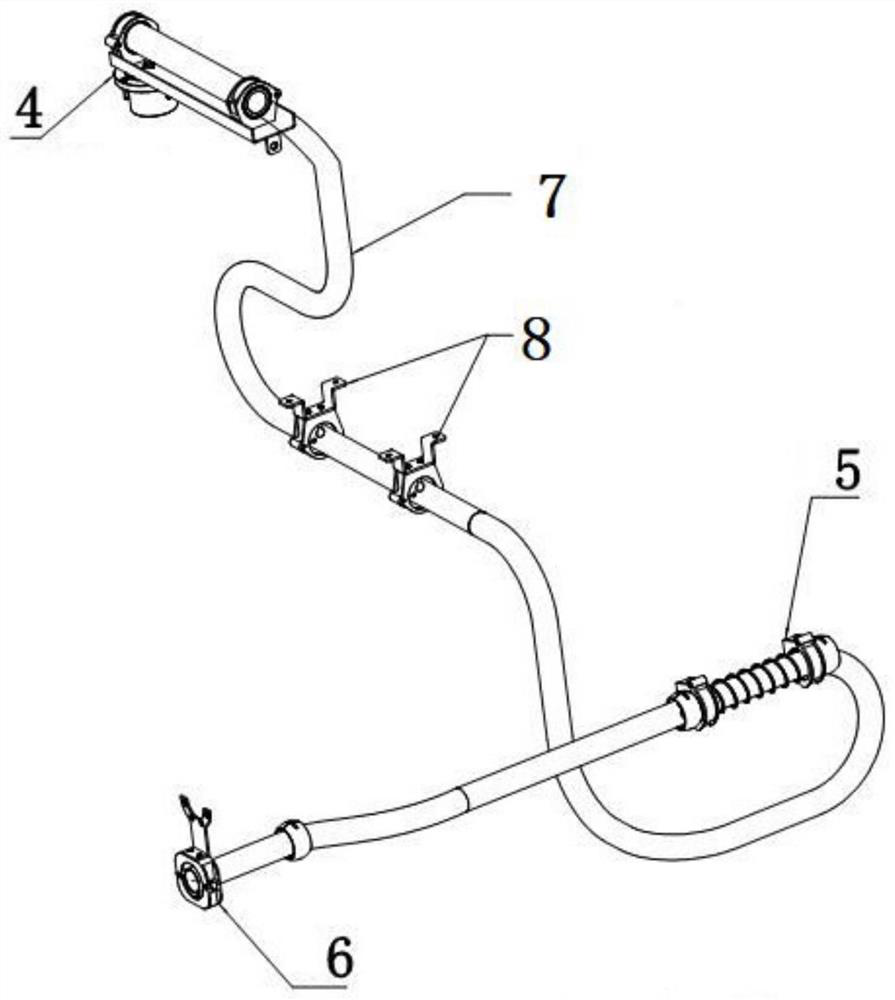

[0057] The pipeline package device is wound around the six-axis robot 1, one end of the pipeline package device is connected to the six-axis robot 106, and the other end is connected to the rob...

Embodiment 2

[0062] According to a specific embodiment of the present invention, the six-axis robot wire pack device of the present invention will be described in detail below.

[0063] The invention provides a six-axis robot pipeline package device, comprising:

[0064] The pipeline package device, the six-axis robot 1 and the robot mount 3, the six-axis robot 1 includes six robot axes and the mechanical arm, and the six robot axes are the first axis 101 of the robot, the second axis 102 of the robot, the third axis 103 of the robot, and the fourth axis of the robot Axis 104, robot five-axis 105 and robot six-axis 106;

[0065] Robot one axis 101 is connected with robot two axis 102; robot three axis 103, robot four axis 104, robot five axis 105 and robot six axis 106 are connected sequentially;

[0066] The pipeline package device is wound around the six-axis robot 1, one end of the pipeline package device is connected to the six-axis robot 106, and the other end is connected to the rob...

Embodiment 3

[0074] According to a specific embodiment of the present invention, the six-axis robot wire pack device of the present invention will be described in detail below.

[0075] The invention provides a six-axis robot pipeline package device, comprising:

[0076] The pipeline package device, the six-axis robot 1 and the robot mount 3, the six-axis robot 1 includes six robot axes and the mechanical arm, and the six robot axes are the first axis 101 of the robot, the second axis 102 of the robot, the third axis 103 of the robot, and the fourth axis of the robot Axis 104, robot five-axis 105 and robot six-axis 106;

[0077] Robot one axis 101 is connected with robot two axis 102; robot three axis 103, robot four axis 104, robot five axis 105 and robot six axis 106 are connected sequentially;

[0078] The pipeline package device is wound around the six-axis robot 1, one end of the pipeline package device is connected to the six-axis robot 106, and the other end is connected to the rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com