High-safety robot for emergency logistics distribution

A logistics distribution and safety technology, applied in the field of robots, can solve the problems of movement or even collision, unstable movement of moving wheels, and speed reduction of high-safety robots, to achieve the effect of enhancing grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

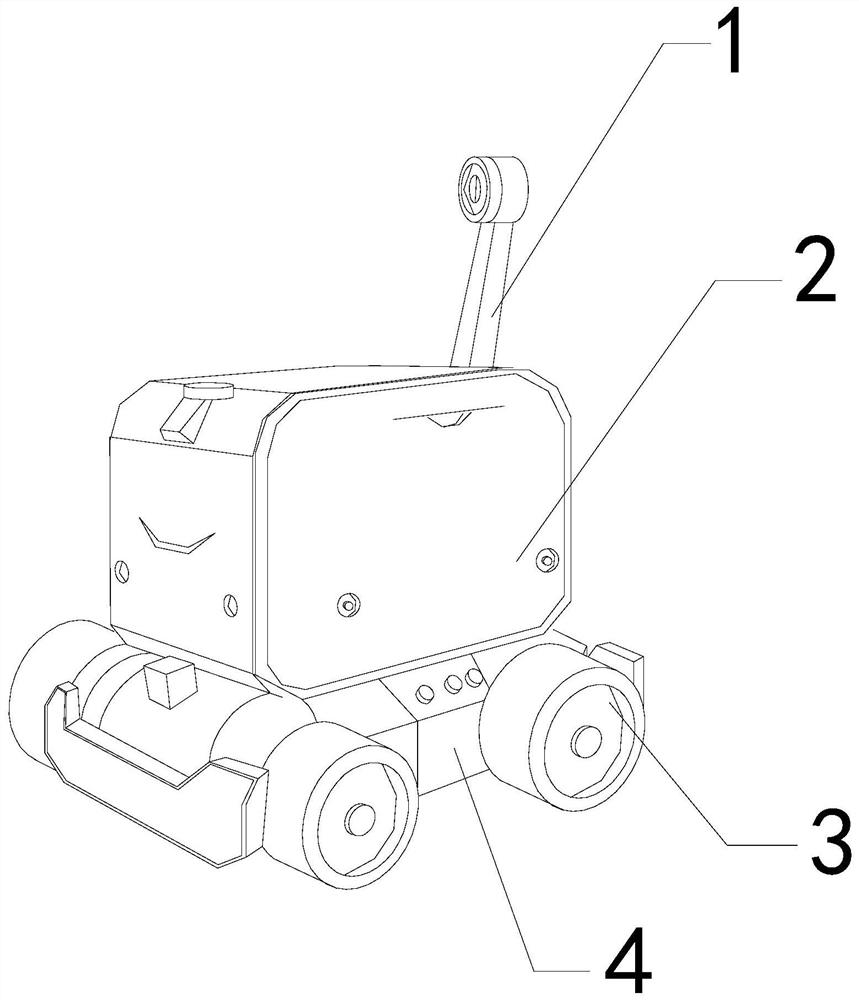

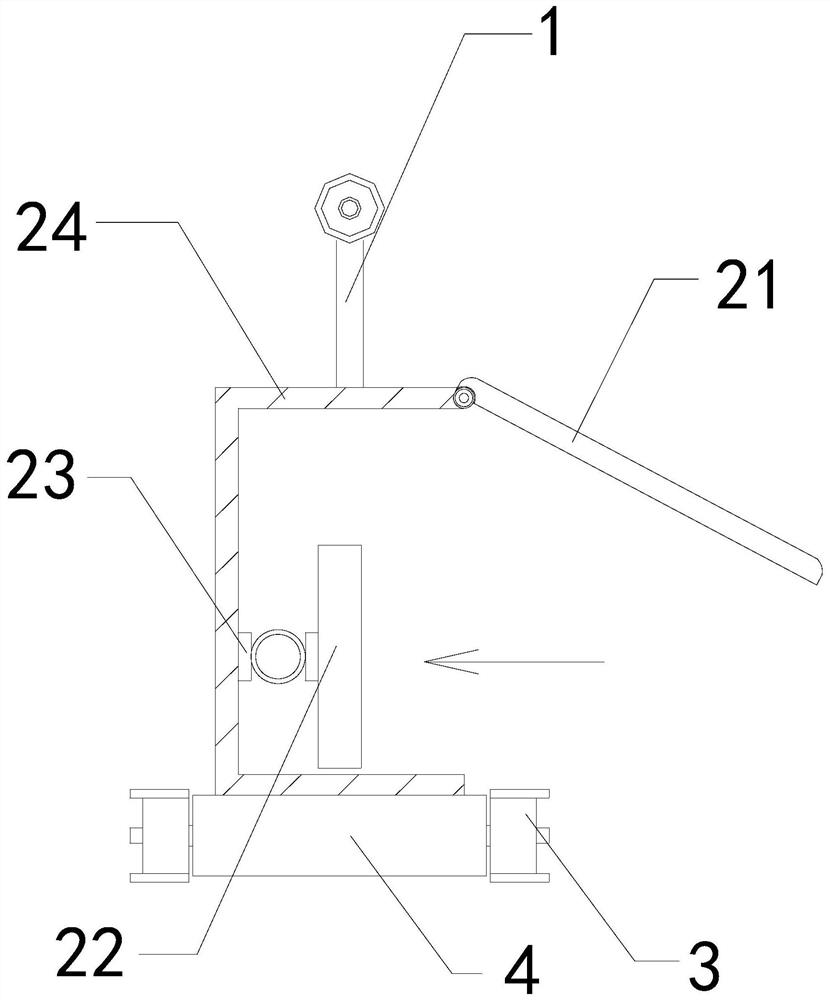

[0031] Such as Figure 1 to Figure 8 Shown:

[0032] The present invention provides a robot with high safety for emergency logistics distribution. Its structure includes a camera 1, a storage box 2, a chassis 3, and a moving wheel 4. The camera 1 is installed at the upper end of the storage box 2 near the rear , the chassis 3 is movably engaged with the side of the moving wheel 4, and the bottom of the storage box 2 is connected to the upper surface of the moving wheel 4; the storage box 2 includes a sealed door 21, a telescopic frame 22, a deformation Frame 23, shell 24, described airtight door 21 is hingedly connected with the right side of shell 24, the left side of described telescopic frame 22 is connected with the right side of deformation frame 23, the left side of described deformation frame 23 is connected with the right side of shell 24 The left side of the inner wall fits together.

[0033] Wherein, the telescopic frame 22 includes an elastic piece a1, a sliding p...

Embodiment 2

[0039] Such as Figure 9-Figure 13 Shown:

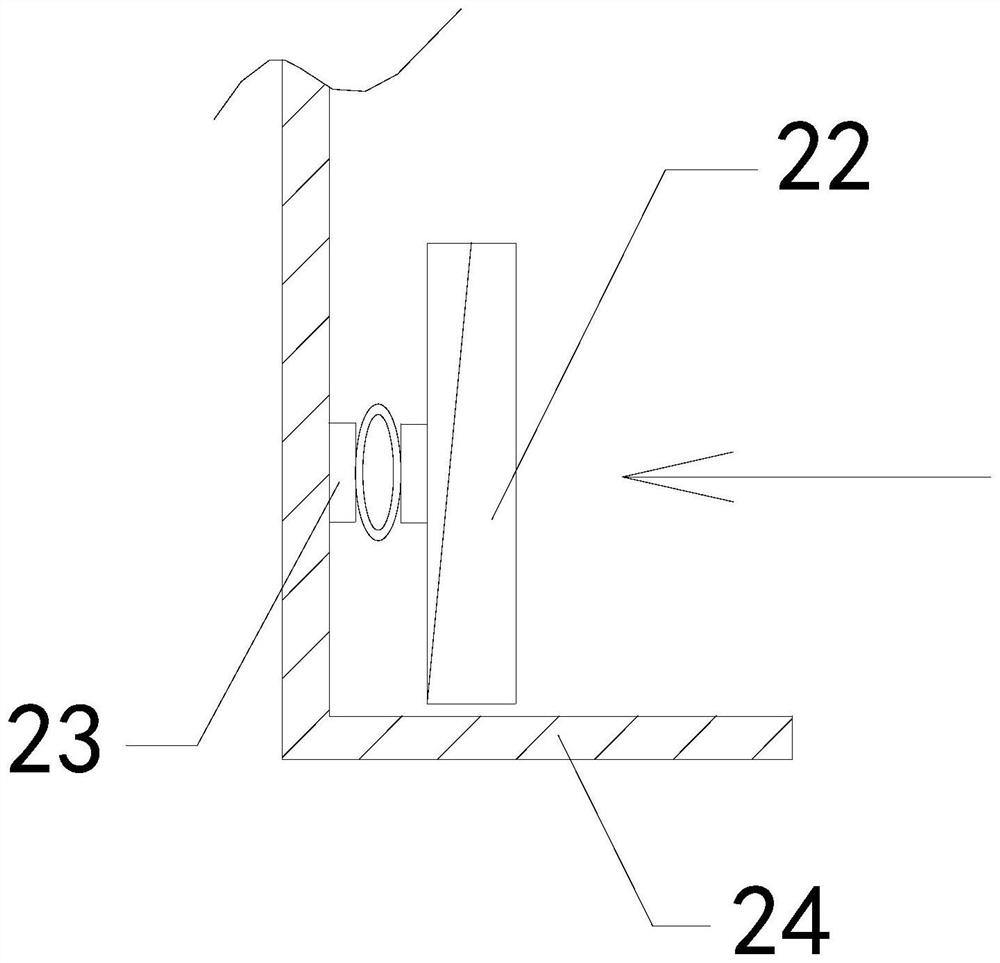

[0040] Wherein, the deformation frame 23 includes a ring body c1, a bearing plate c2, an insert block c3, and a frame c4. The ring body c1 is installed on the inner side of the two load bearing plates c2. The right side of the inner wall of the frame c4 is attached to the left side of the inner wall of the ring body c1, and the ring body c1 can be deformed and contracted by the extrusion of the bearing plate c2, so that the insertion block c3 can be inserted into the inside of the frame c4 Location.

[0041] Wherein, the insertion block c3 includes a thrust piece c31, a middle solid plate c32, and a grip surface c33. The thrust piece c31 is installed between the middle solid plate c32 and the inner wall of the grip surface c33, and the grip surface c33 The inner side fits with the solid plate c32, and the gripping surface c33 is made of nitrile rubber material with high density, and the thrust generated by the thrust plate c31 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com