Ligusticum wallichii tea and preparation process thereof

A production process, the technology of Chuanxiong tea, applied in the field of Chuanxiong tea and its production process, can solve the problems of ignoring the medicinal value and utilization of Chuanxiong leaves, and achieve the effects of highlighting practical value, scientific design, and improving myocardial ischemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

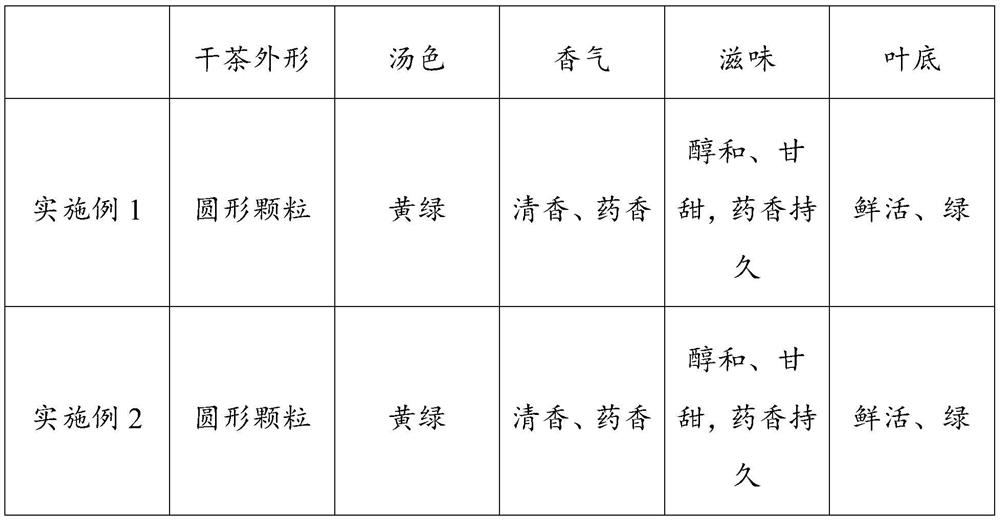

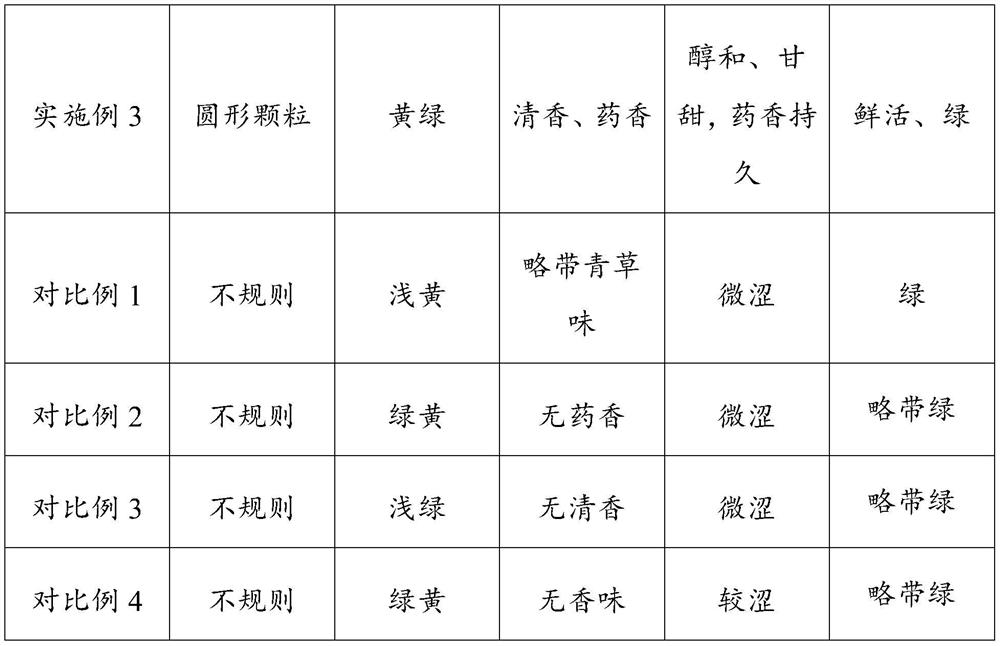

Embodiment 1

[0034] A process for making Chuanxiong tea, comprising the following steps:

[0035] S1. Cooling: spread the fresh leaves of Rhizoma Chuanxiong until the water content of the fresh leaves reaches 85%;

[0036] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea inlet and start throwing leaves when the temperature reaches 200°C. The amount of leaf throwing is 1kg / min, and the fresh leaves are cleaned at a high temperature at 250°C until the green smell of fresh leaves disappears. Time to finish;

[0037] S3. Cooling: cooling the finished leaves at 20°C for 1.5h;

[0038] S4. Kneading: Knead the cooled leaves while hot under hot and humid conditions, control the kneading temperature to be 20°C, and the relative humidity to be 85%, and knead for 50 minutes;

[0039] S5. The first drying: first control the temperature at 80°C and dry for 0.5h; then control the temperature at 100°C and dry for 0.5h;

[0040] S6. Fermentation: ferment for 4 hours at 45°C an...

Embodiment 2

[0044] A process for making Chuanxiong tea, comprising the following steps:

[0045] S1. Cooling: Spread the fresh leaves of Rhizoma Chuanxiong thinly until the water content of the fresh leaves reaches 90%;

[0046] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea inlet and start throwing leaves when the temperature reaches 200°C. The amount of leaves thrown is 1kg / min. Fresh leaves are cleaned at a high temperature at 300°C until the fresh green flavor of fresh leaves disappears. Time to finish;

[0047] S3. Cooling: cooling the finished leaves at 30°C for 2.5 hours;

[0048] S4. Kneading: Knead the cooled blade while it is hot under hot and humid conditions, control the kneading temperature to be 30° C., and the relative humidity to be 95%, and knead for 60 minutes;

[0049] S5. The first drying: first control the temperature at 100°C and dry for 1 hour; then control the temperature at 120°C and dry for 1 hour;

[0050] S6. Fermentation: ferment...

Embodiment 3

[0054] A process for making Chuanxiong tea, comprising the following steps:

[0055]S1. Cooling: spread the fresh leaves of Rhizoma Chuanxiong thinly until the water content of the fresh leaves reaches 88%;

[0056] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea inlet and start throwing leaves when the temperature reaches 200°C. The amount of leaf throwing is 1kg / min, and the fresh leaves are cleaned at a high temperature at 260°C until the fresh green taste of the fresh leaves disappears. Time to finish;

[0057] S3. Cooling: cooling the finished leaves at 5°C for 2 hours;

[0058] S4. Kneading: Knead the cooled leaves while they are hot under hot and humid conditions, control the kneading temperature to 25°C, and the relative humidity to 90%, and knead for 55 minutes;

[0059] S5. The first drying: first control the temperature at 90°C and dry for 1 hour; then control the temperature at 110°C and dry for 0.5 hour;

[0060] S6. Fermentation: fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com