Press fitting clamp for gear shifting fork assembly pin and working method of press fitting clamp

A shift fork and pin press-fitting technology, which is applied in metal processing, manufacturing tools, workpiece clamping devices, etc., can solve the problems of missing workpieces and low precision of press-fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] It can be understood that the present invention achieves the purpose of the present invention through some embodiments.

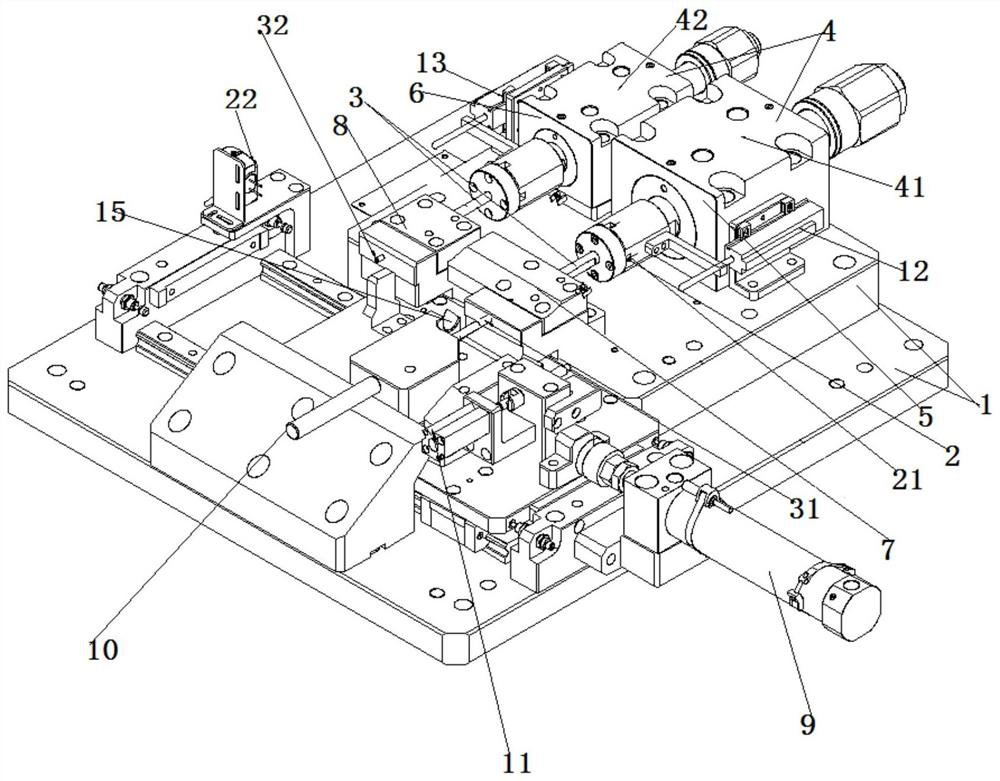

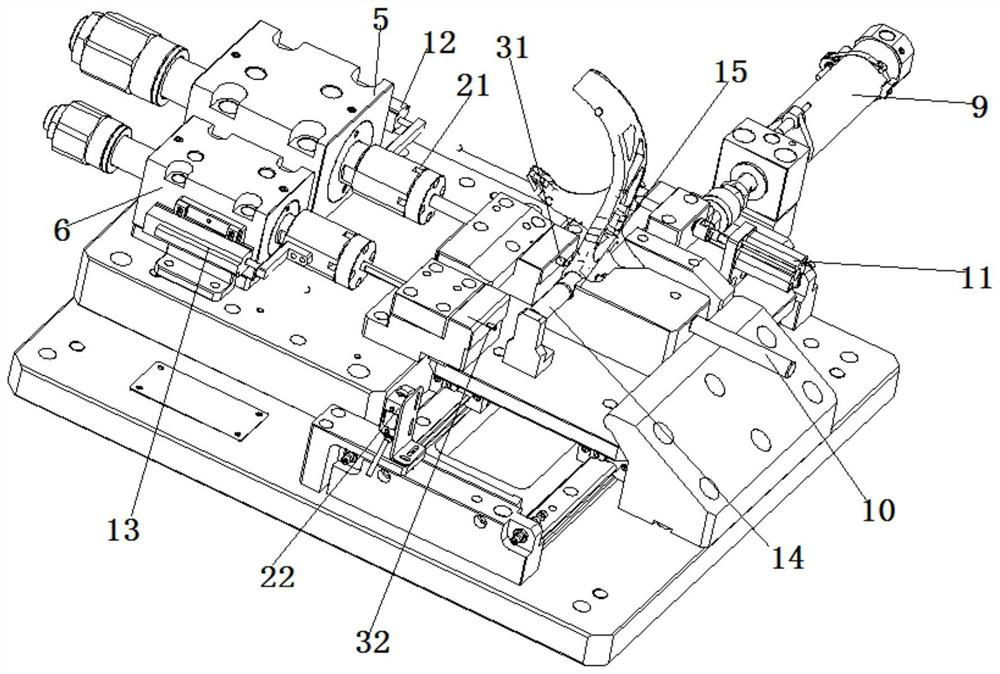

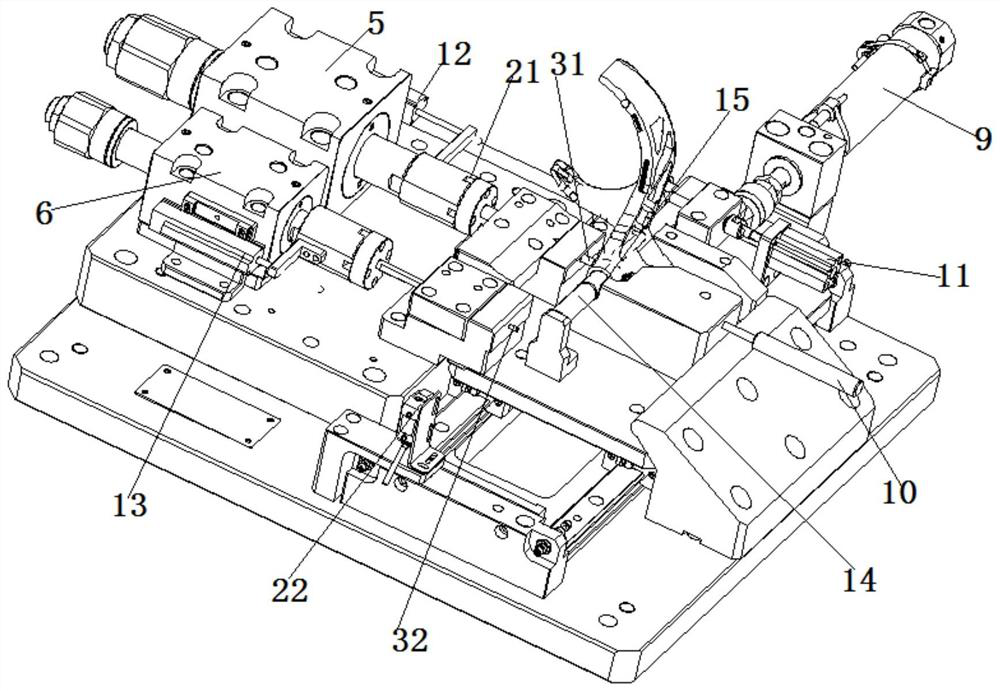

[0029] Such as figure 1 As shown, the present invention provides a shift fork assembly pin press-fitting jig, including a base 1, on which a first pressure sensor 21 and a second pressure sensor 22 are arranged, and the first pressure sensor 21 is used for In order to detect whether the first elastic pin 31 is missing installed on the first elastic pin press assembly 41, the second pressure sensor 22 is used to detect whether the second elastic pin 32 is missing installed on the second elastic pin press assembly On the component 42, the base 1 is provided with a clamping body 15 and a shift fork error-proof driving member 11, the clamping body 15 clamps a workpiece 14 to be pressed, and the clamping body 15 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com