Laser marking tool

A technology of laser marking and tooling, which is applied in the field of laser marking, can solve the problems of consuming human resources, not having enough space for special-shaped elbows, and not being able to configure a large flat working platform for laser marking machines, so as to prevent front and rear offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

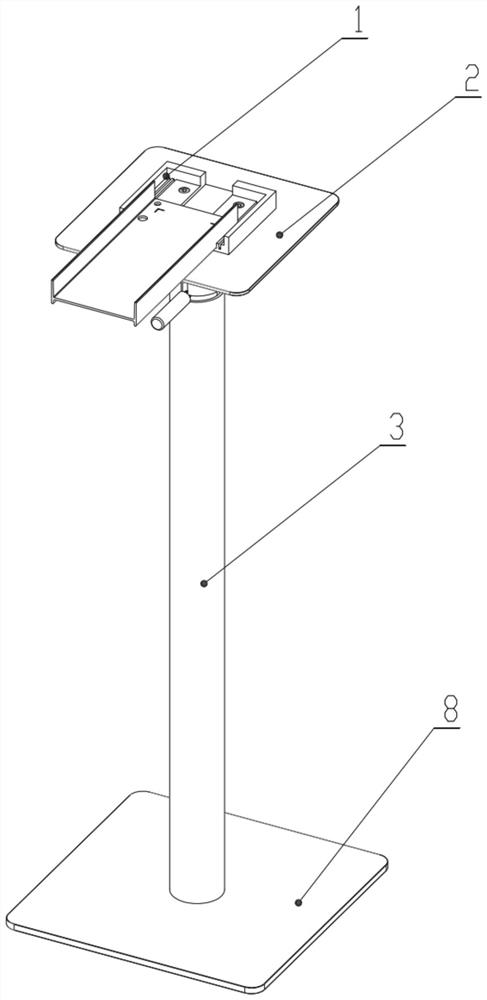

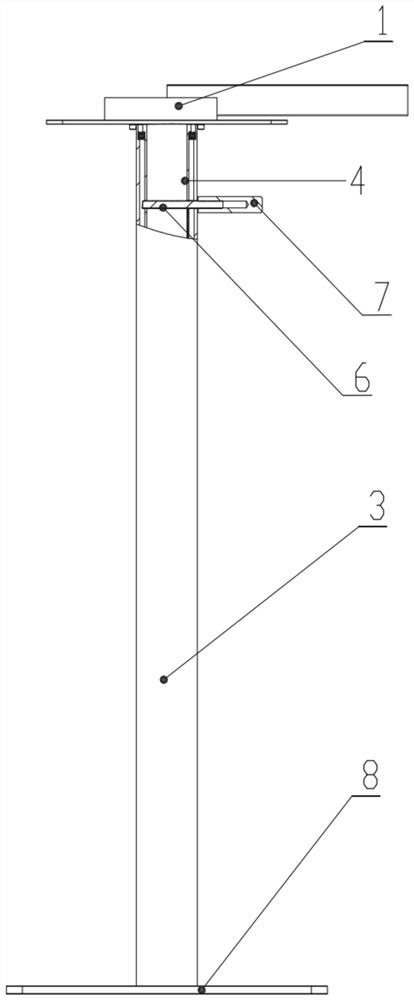

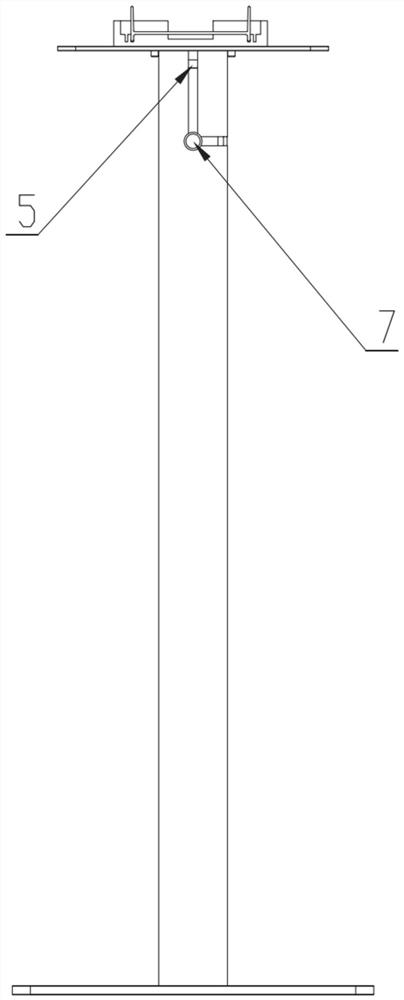

[0023] combine Figure 1-Figure 8 , this embodiment discloses a laser marking tool, including a limit working platform 1, the limit working platform 1 is used for placing H-shaped materials.

[0024] The overall outline of the position-limiting working platform 1 is a cuboid, including a bottom plate 11, a side wall 12, and a rear wall 13. The side walls 12 are respectively located on the left and right sides of the bottom plate 11, and the rear wall 13 is located on the rear side of the bottom plate 11. On the edge of the bottom plate 11, the front end of the space-limiting working platform 1 is an open structure, which is convenient for profiles to be sent to the bottom plate 11 from the front end, and the rear wall 13 also plays a position-limiting role to prevent the profiles from shifting back and forth.

[0025] There are also several card slots 14 on the bottom plate 11. The direction of the card slots 14 is from front to back, and the position of the card slots 14 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com