Ultrafine powder packaging machine

An ultra-fine powder, packaging machine technology, applied in the directions of packaging, transportation and packaging, packaging items, etc., can solve the problems of harming the health of operators, increasing factory production costs, loose materials in packaging bags, etc. The effect of packaging volume, reducing powder waste and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

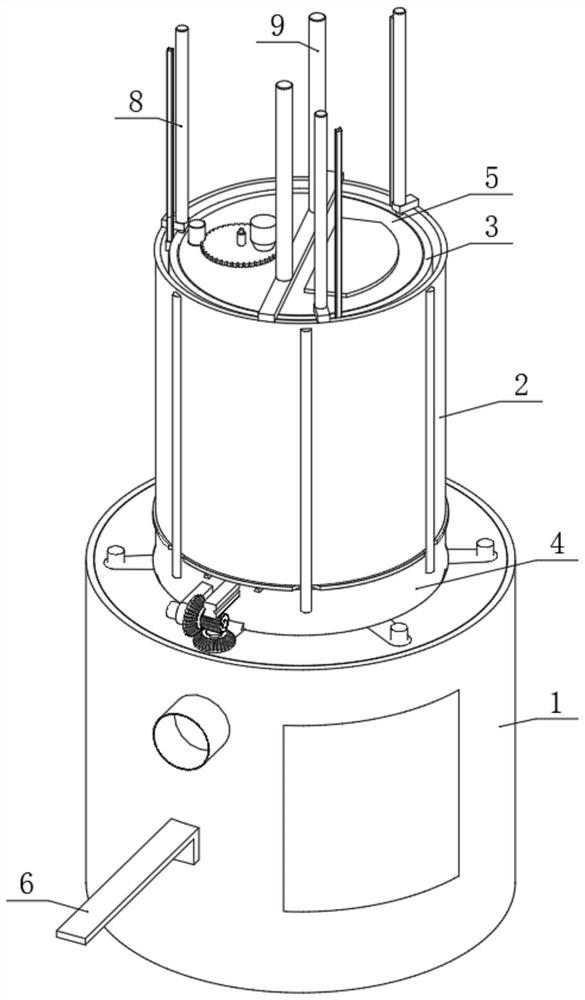

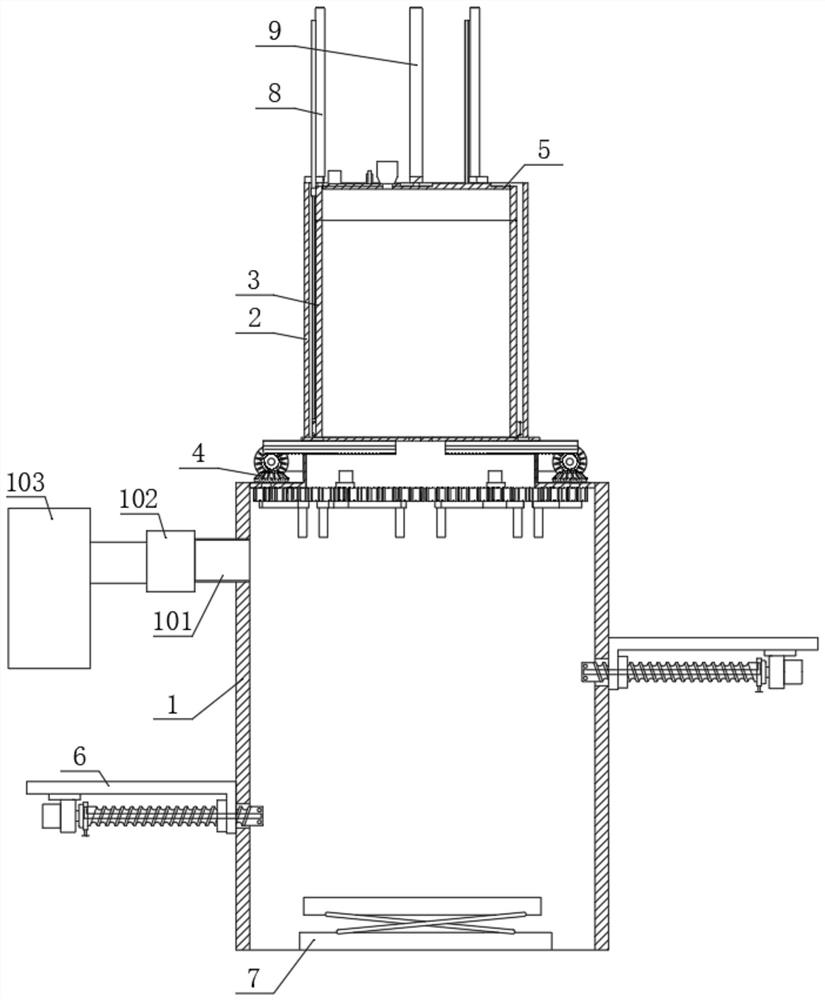

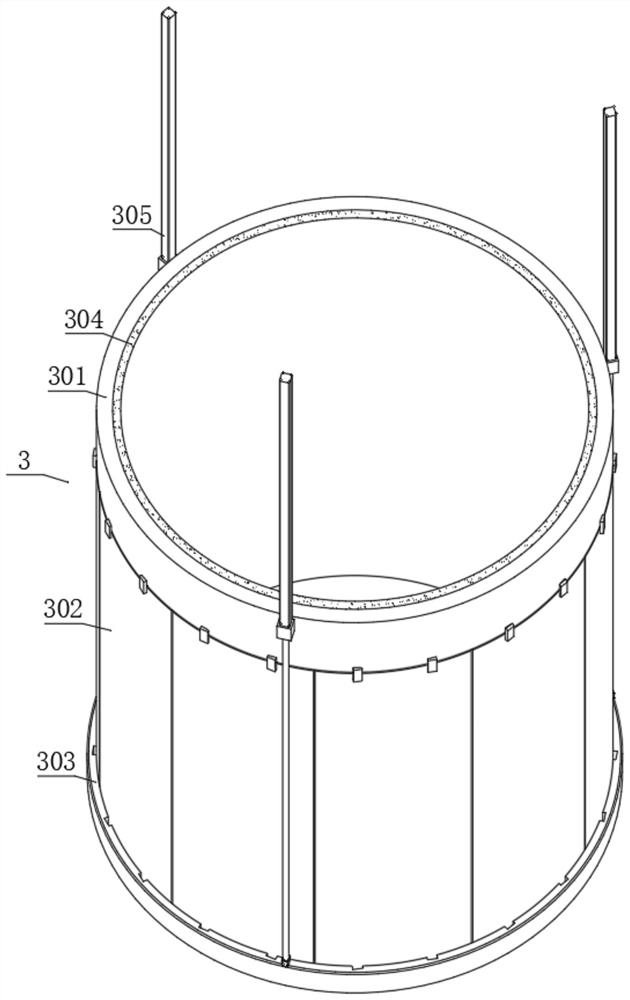

[0023] see Figure 1-2, an ultrafine powder packaging machine, comprising a bottom cylinder 1, a gate mechanism 4, an outer support cylinder 2, an inner cylinder mechanism 3 and a rotary blowing mechanism 6, and the gate mechanism 4 is fixedly connected to the bottom cylinder 1 The top end of the outer support cylinder 2 is fixedly connected to the top of the gate mechanism 4, the inner cylinder mechanism 3 is arranged in the outer support cylinder 2, and the bottom end of the inner cylinder mechanism 3 Overlapped on the top of the gate mechanism 4, the inner cylinder mechanism 3 is provided with a pressure plate mechanism 5, the rotary blowing mechanism 6 is fixedly connected to the side wall of the bottom cylinder 1, and the rotary The purge end of the purging mechanism 6 is inserted into the bottom cylinder 1; the top end of the inner cylinder mechanism 3 is fixedly connected with a cross bar, and a third cylinder 9 is vertically fixedly connected to the cross bar, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com