Autoclaved aerated concrete wallboard

A technology of autoclaved aeration and concrete, which is applied in the direction of walls, buildings, building components, etc., can solve the problems of complex wall panel steps, large manpower investment, and reduced construction progress, so as to achieve a good noise reduction environment, improve safety, and guarantee Efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

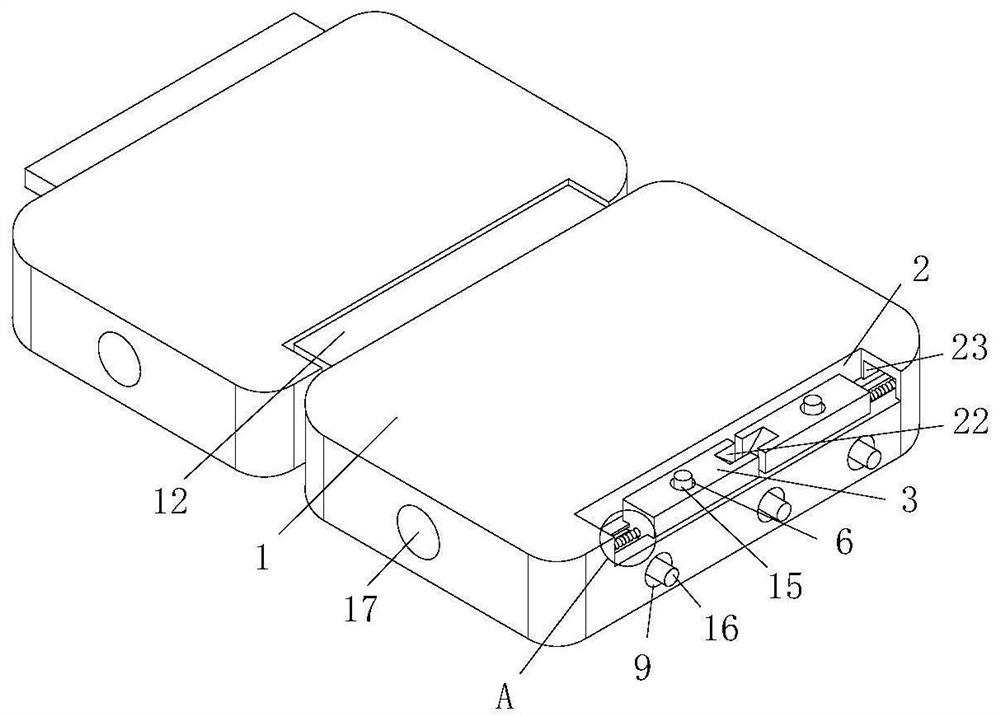

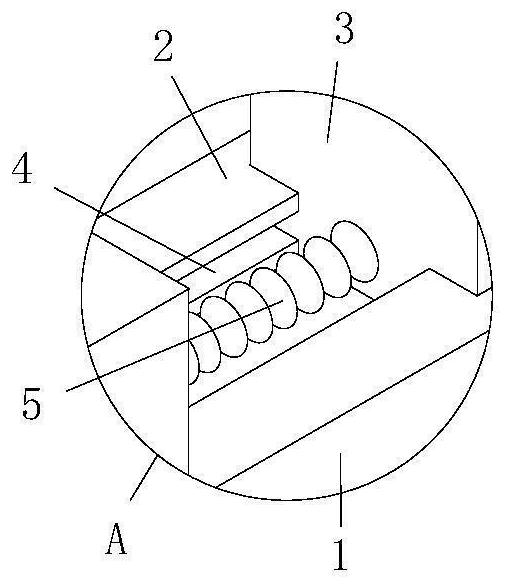

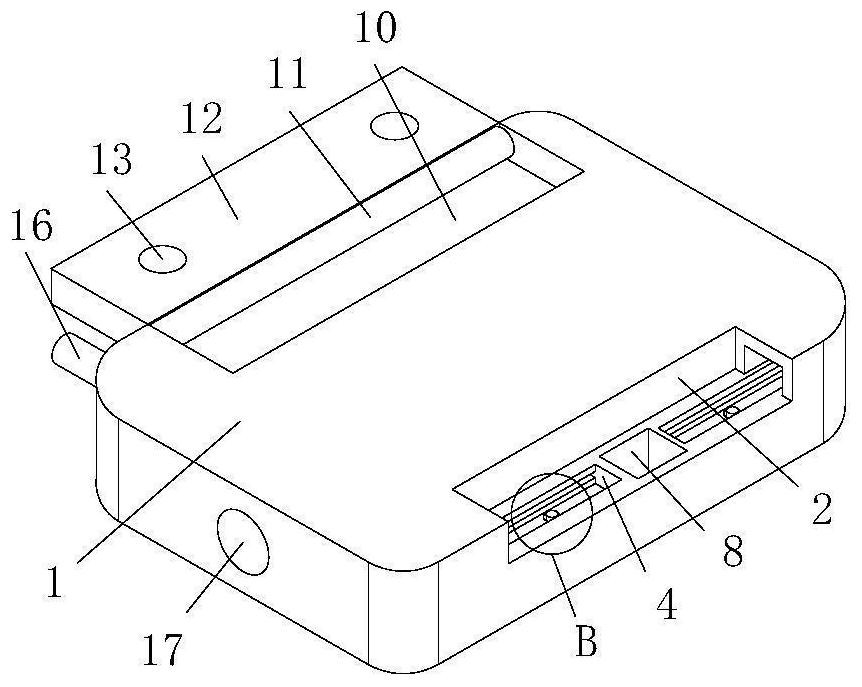

[0035] see Figure 1-5, the present invention provides a technical solution: an autoclaved aerated concrete wallboard, including two wallboards 1, the structures on the two wallboards 1 are the same, so the following mainly describes the structure on one wallboard 1, the wallboard The upper side of 1 is provided with a chute 2, and the inside of the chute 2 is slidably connected with a clamping plate 3, and the inside of the wall plate 1 is provided with a limiting groove 4 communicating with the chute 2, and the lower side of the clamping plate 3 is connected with the limiting groove 4. The shape of the groove 4 is cross-shaped, the lower side of the clamping plate 3 is slidably connected to the inside of the limiting groove 4, and the inside of the wallboard 1 is provided with a clamping groove 23 communicating with the chute 2 and the limiting groove 4. The left side of 3 is fixedly connected with return spring 5, and the left end of return spring 5 is fixedly connected in ...

Embodiment 2

[0038] see Image 6 , on the basis of Embodiment 1, the noise reduction buffer device includes an inner plate 18, the surface of the inner plate 18 is fixedly connected to the inside of the wall panel 1, and the surface of the inner plate 18 is provided with a flow groove 19, and the inside of the flow groove 19 is fixedly connected There is a fixed rod 21, and the surface of the fixed rod 21 is connected with the rotating plate 20, and the surface of the rotating plate 20 is connected with the rotation of the circulation groove 19. By putting the pouring pipe into the inside of the feed port 17, when the concrete enters the wallboard 1 After the interior, the concrete is in contact with the rotating plate 20, and through the rotation of the rotating plate 20 and the fixed rod 21, no direct impact will be generated between the concrete and the wall panel 1, and the rotation of the fixed rod 21 and the rotating plate 20 can play The protective effect on the wall panel 1 improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com