Sleeving and welding method for inner heat insulation cylinder and outer heat insulation cylinder of aero-engine

An aero-engine and welding method technology, applied in welding equipment, electron beam welding equipment, applications, etc., can solve problems such as easy generation of air holes and nail tips, increase deformation, and affect product performance, so as to achieve package welding process optimization and reduce The influence of product performance and the effect of improving the quality of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

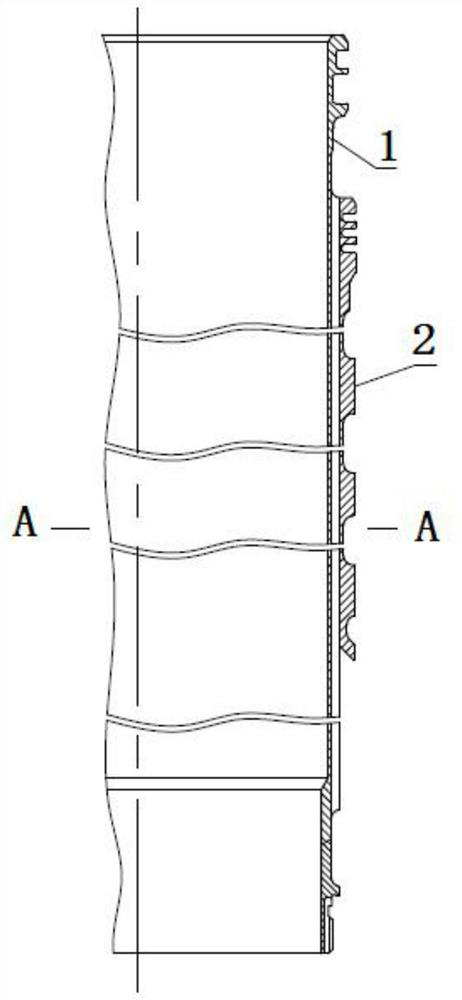

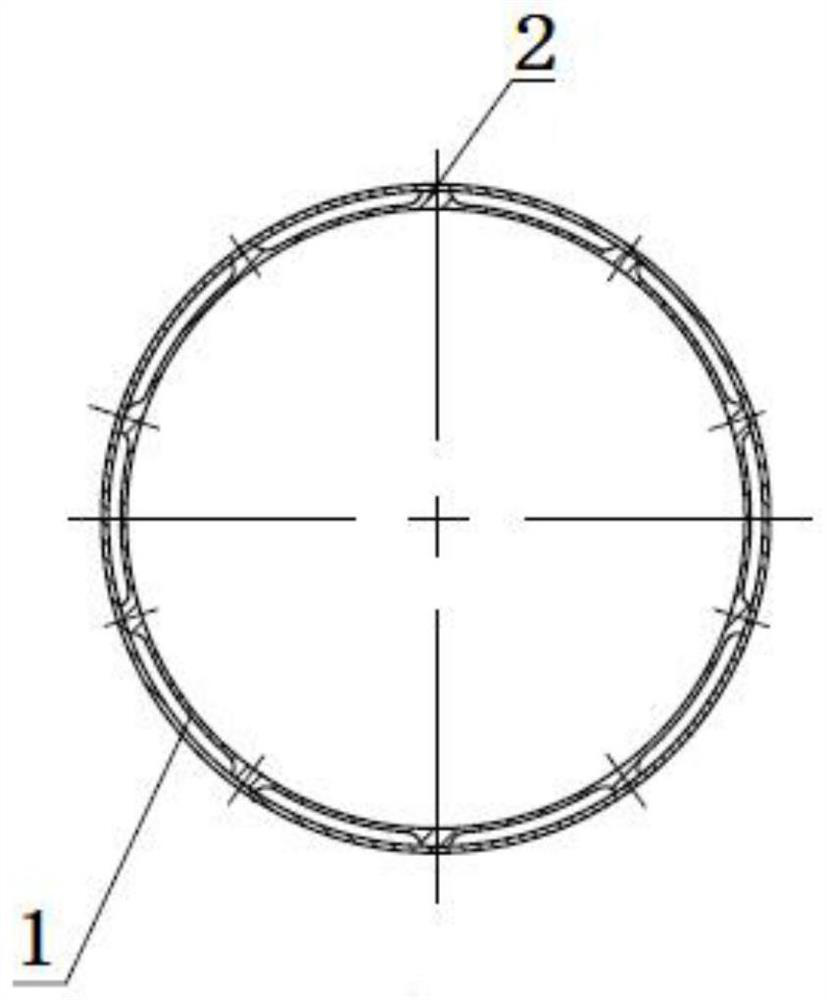

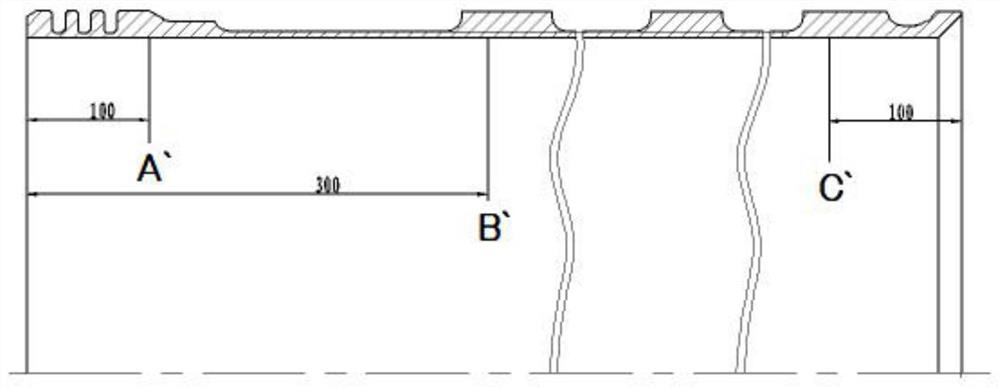

[0023] Such as Figure 1-2 As shown, the connecting structure of the inner heat insulation cylinder and the outer heat insulation cylinder required by the present invention, a method for the welding of the inner heat insulation cylinder 1 and the outer heat insulation cylinder 2 of an aero-engine, comprises the following steps: Step 1. Select an inner heat insulation cylinder 1 and an outer heat insulation cylinder 2 from the finished product warehouse of the inner heat insulation cylinder 1 and the outer heat insulation cylinder 2, and use sandpaper to clean the reinforcement ribs of the inner heat insulation cylinder 1 and the outer heat insulation cylinder 2 The surface of the inner wall is polished clean; step 2, select the same cross-section at the upper, middle and lower parts of the outer heat insulation cylinder 2 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com