Take-up equipment with adjustable pay-off rack

A wire take-up device and an adjustable technology, which is applied in the field of wire take-up machines, can solve problems such as the influence of enameled wire surface quality and local accumulation of enameled wire, and achieve the effect of improving state stability and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

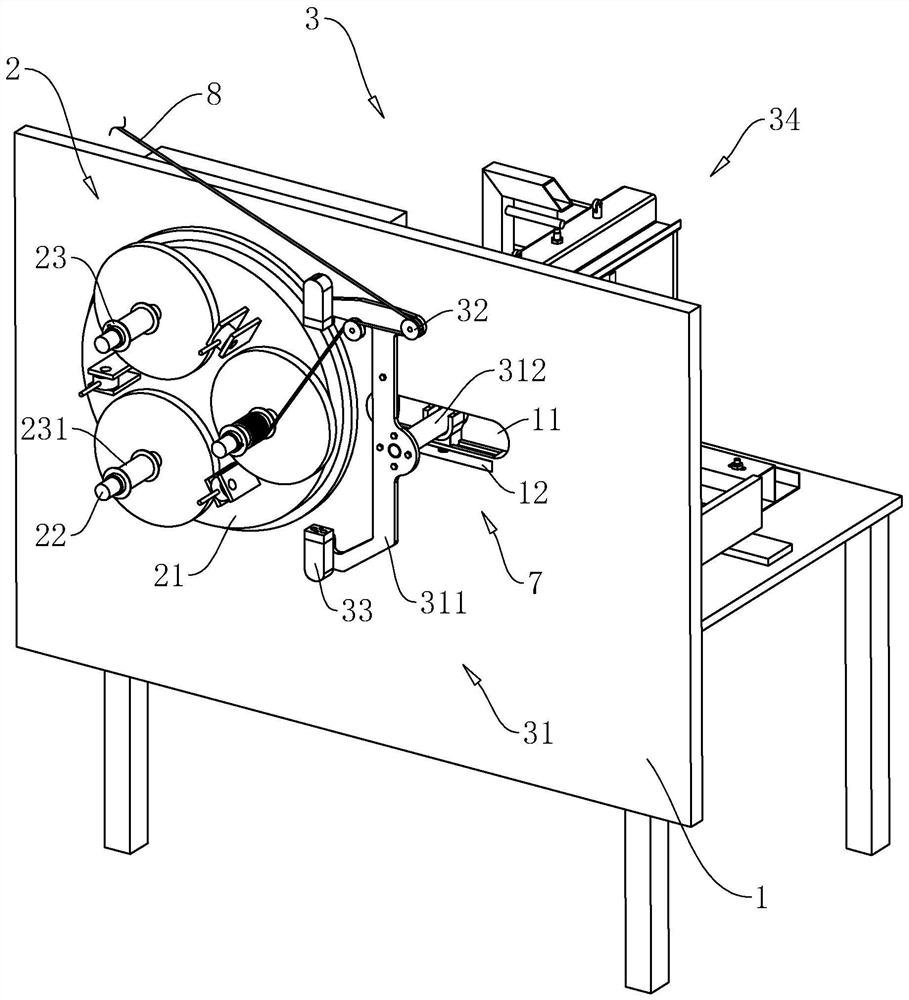

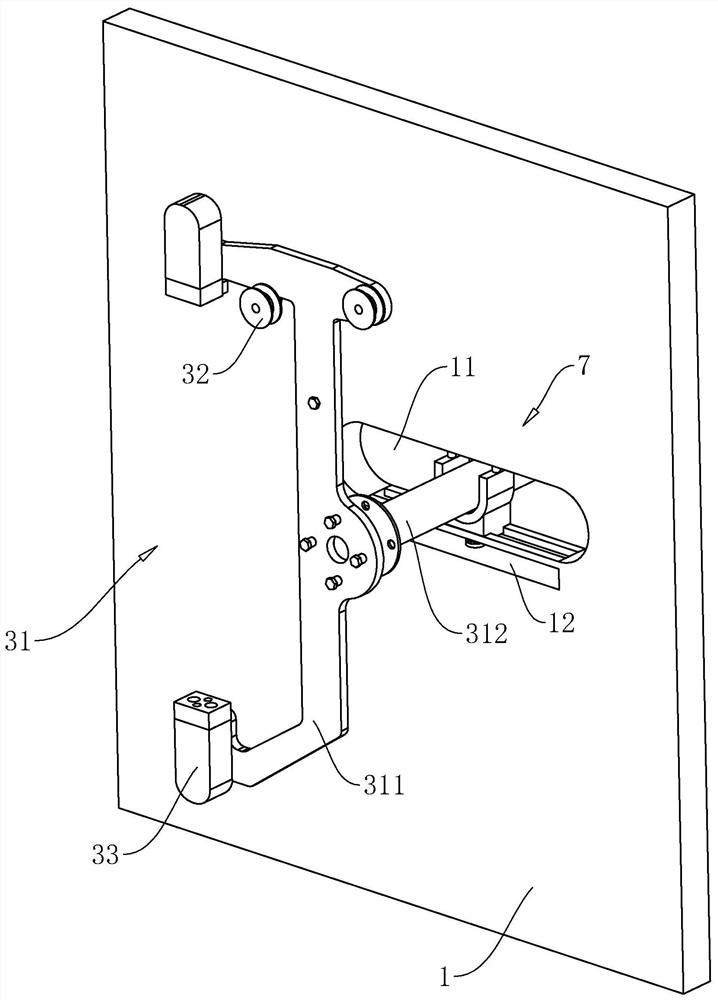

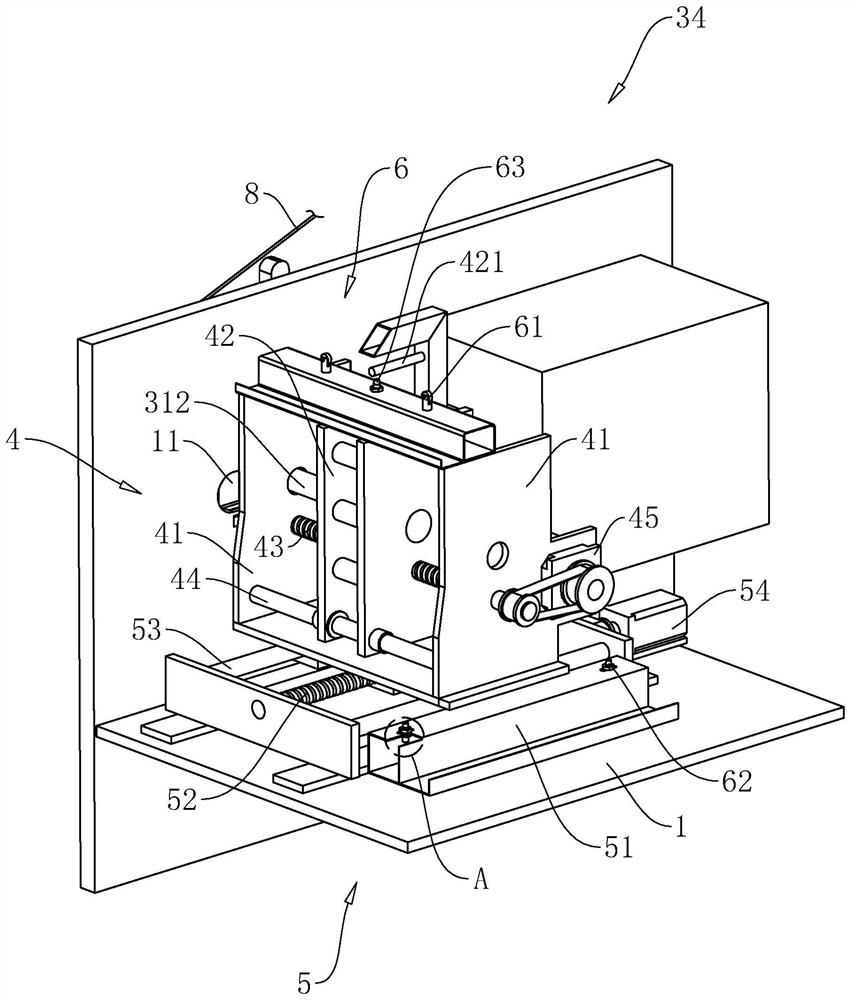

[0033] The following is attached Figure 1-6 The application is described in further detail.

[0034]The embodiment of the present application discloses an adjustable wire take-up device on the pay-off stand, such as figure 1 As shown, including a frame 1, the frame 1 is provided with a take-up device 2 and a guide device 3, and the take-up device 2 is a three-axis chain-type take-up machine, which is used for continuous winding of the finished product of the enameled wire 8; The device 3 is used to guide the enameled wire 8 before the enameled wire 8 enters the wire take-up device 2, so that the enameled wire 8 has an overall stable traveling state.

[0035] Such as figure 1 As shown, the take-up device 2 includes a take-up reel 21, a take-up rod 22 and a driving mechanism, the take-up reel 21 is rotationally connected with the frame 1, and there are three take-up rods 22 which are all rotatably connected with the take-up reel 21, and the take-up The rotation plane of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap