Fe-al-based alloy vibration-damping component and method for manufacturing same

A manufacturing method, fe-al technology, applied in the direction of manufacturing tools, additive manufacturing, furnaces, etc., which can solve problems such as complex shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

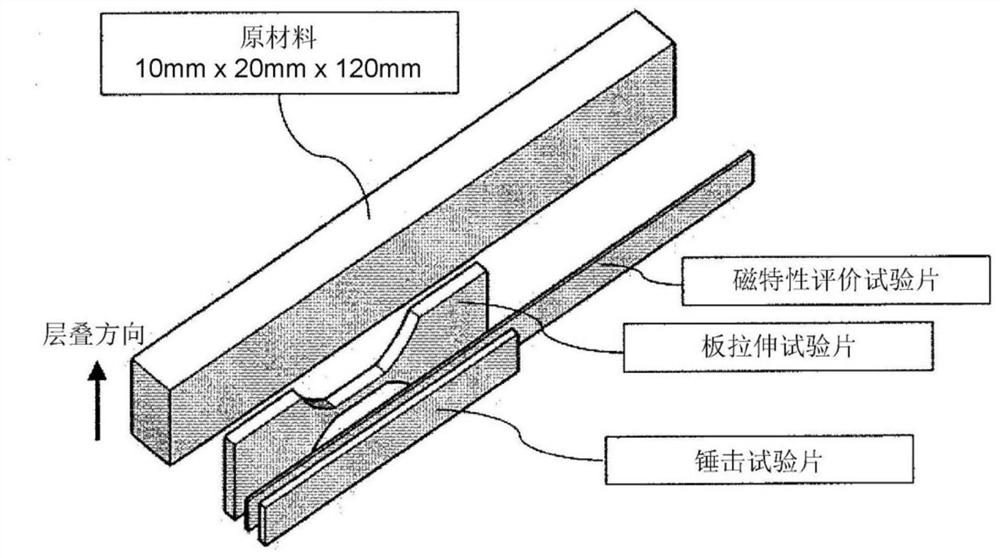

[0041] Gas atomized powders containing 6.43%, 8.32%, and 10.40% of Al in mass % and the remainder containing Fe and unavoidable impurities were produced and classified into 10 μm to 53 μm. Gas atomization is carried out in the following manner: high-frequency dissolution is performed in vacuum, the molten alloy is dropped from a nozzle with a diameter of 5 mm under the crucible, and sprayed with high-pressure argon gas. Using this as a raw material powder, using a three-dimensional lamination molding machine (manufactured by EOS Corporation, EOS-M290), using S45C as a base plate, a powder bed method was used to produce a width of 10mm, a length of 120mm, and a stacking height of 20mm by high-speed melting and rapid solidification by laser irradiation. The elongated shape of the body ( figure 1 ). The lamination thickness of each layer was 40 μm, and the irradiation direction was rotated by 67° for each layer. The diameter of the laser beam is about 0.1mm, and the laser outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com