A kind of gold-platinum alloy inspection quality material for space gravitational wave detection inertial sensor and preparation method thereof

An inertial sensor, gold-platinum alloy technology, applied in the field of metal materials, to achieve the effect of refining grains, ultra-low magnetic susceptibility, and promoting leap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

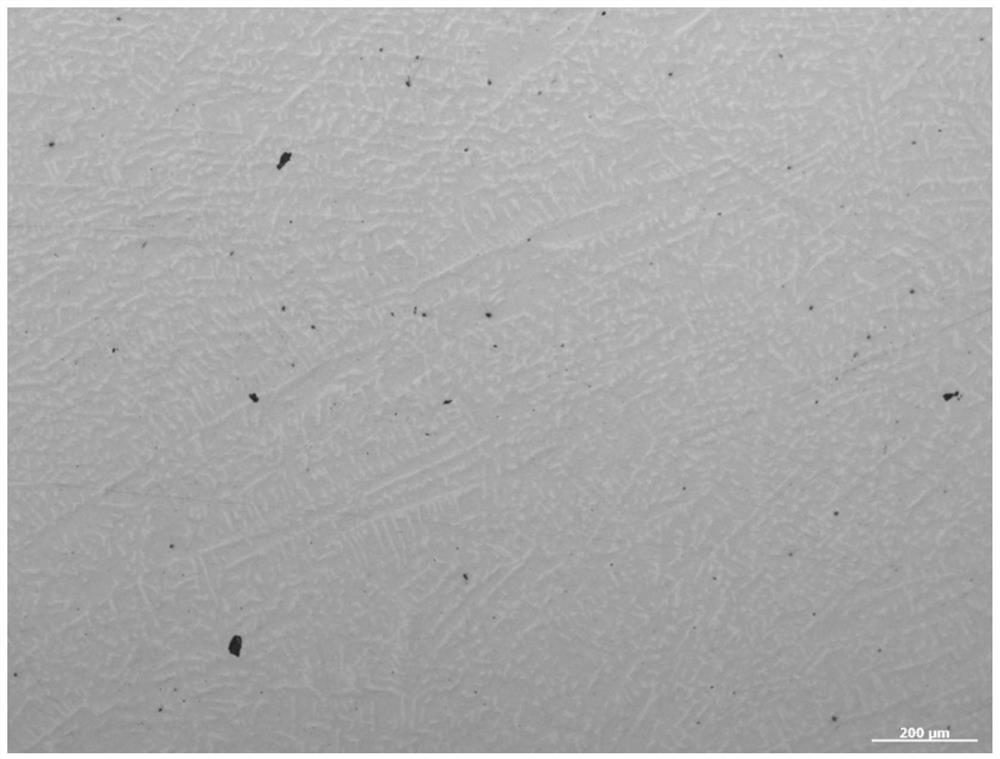

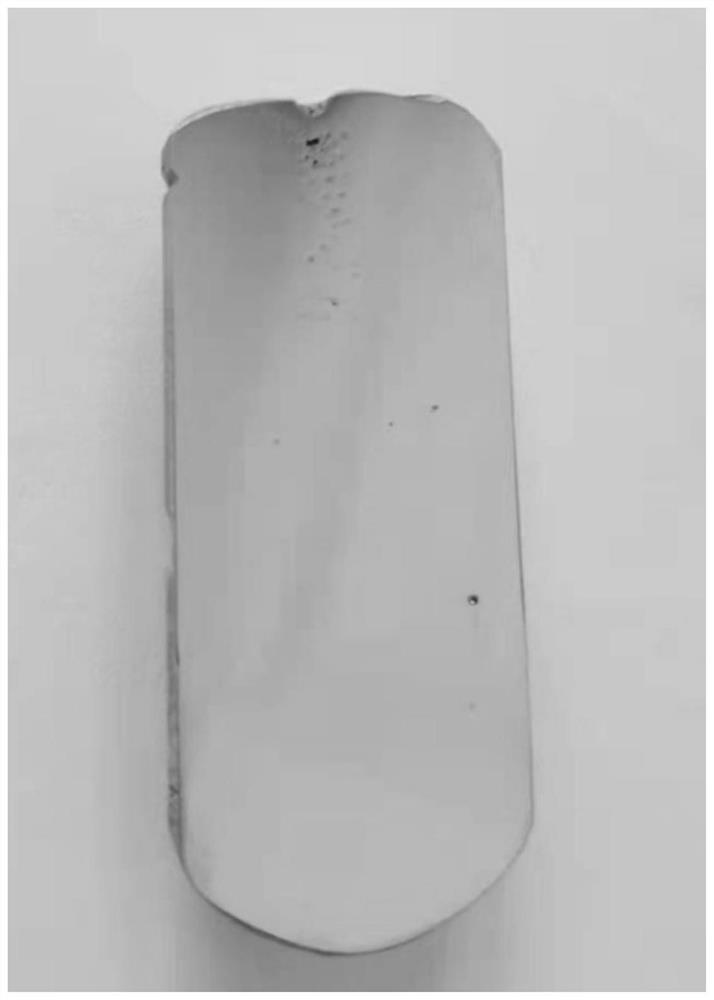

[0036] Example 1 (ordinary casting)

[0037] In this embodiment, gold and platinum with a purity of 99.99 wt.% are first purchased as raw materials, wherein the contents of impurity elements Fe, Ni, and Co are all lower than 0.001 wt.%. Under the aid of ultrasonic waves, the gold and platinum bulk raw materials were washed three times with acetone solution and deionized water successively, and then dried in a 400°C oven after drying. The alloy is configured according to the design composition, wherein the mass percentage of elemental platinum is 26.5 wt.%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, the prepared gold and platinum raw materials are placed in a high-purity and high-temperature resistant quartz crucible (the crucible is made of grade II quartz sand, SiO 2 purity ≥ 99.98wt%), close the furnace door to evacuate, when the vacuum degree in the vacuum induction me...

Embodiment 2

[0039] Example 2 (ordinary casting + rare earth lanthanum La)

[0040] In this embodiment, gold and platinum with a purity of 99.99 wt.% are first purchased as raw materials, wherein the contents of impurity elements Fe, Ni, and Co are all lower than 0.001 wt.%. Under the aid of ultrasonic waves, the gold and platinum bulk raw materials were washed three times with acetone solution and deionized water successively, and then dried in a 400°C oven after drying. The alloy is configured according to the design composition, wherein the mass percentage content of element platinum is 26.5 wt.%, the mass percentage content of modified rare earth element lanthanum La is 0.5%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, put the prepared gold and platinum raw materials in a high-purity and high-temperature resistant quartz crucible, close the furnace door and evacuate, when the vacuum...

Embodiment 3

[0042] Example 3 (ordinary casting + boron element)

[0043] In this embodiment, gold and platinum with a purity of 99.99 wt.% are first purchased as raw materials, wherein the contents of impurity elements Fe, Ni, and Co are all lower than 0.001 wt.%. Under the aid of ultrasonic waves, the gold and platinum bulk raw materials were washed three times with acetone solution and deionized water successively, and then dried in a 400°C oven after drying. The alloy is prepared according to the design composition, wherein the mass percentage of element platinum is 26.5 wt.%, the mass percentage of modified element boron B is 0.05%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, put the prepared gold and platinum raw materials in a high-purity and high-temperature resistant quartz crucible, close the furnace door and evacuate, when the vacuum degree in the vacuum induction melting cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com