Gold-platinum alloy quality inspection material for space gravitational wave detection inertial sensor and preparation method of gold-platinum alloy quality inspection material

An inertial sensor, gold-platinum alloy technology, applied in the field of metal materials to achieve uniform chemical composition distribution, avoid contact and pollution, and refine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

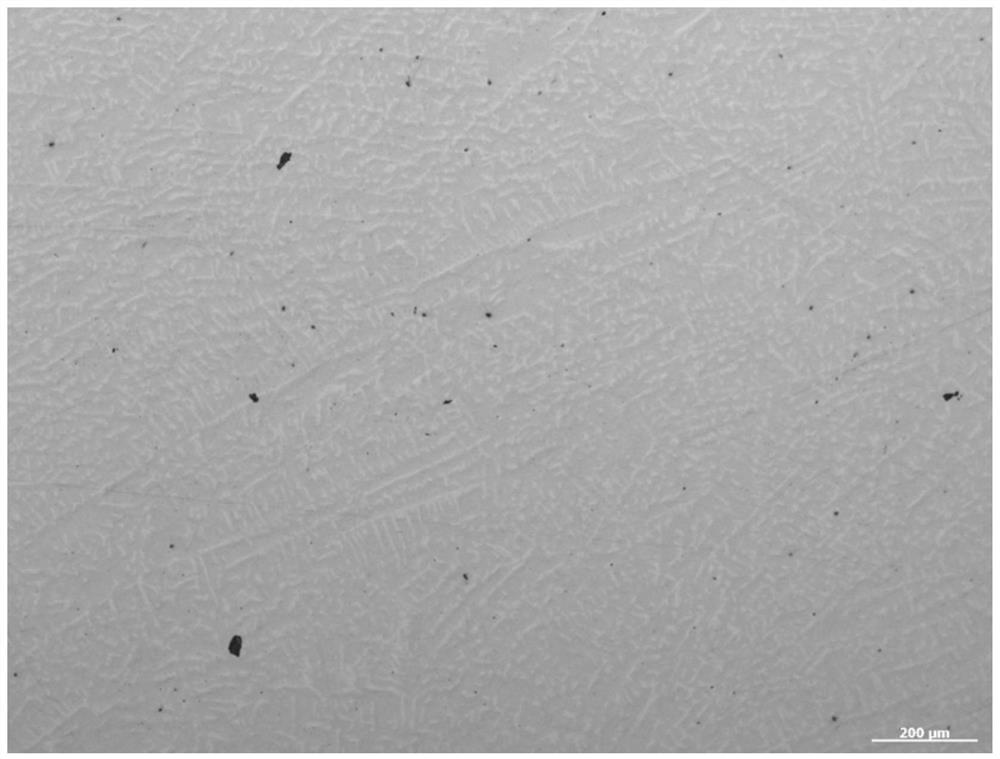

[0036] Embodiment 1 (common casting)

[0037] In this embodiment, gold and platinum with a purity of 99.99wt.% are first purchased as raw materials, and the contents of impurity elements iron Fe, nickel Ni, and cobalt Co are all lower than 0.001wt.%. Under the assisted action of ultrasonic waves, the raw materials of gold and platinum blocks were washed three times with acetone solution and deionized water respectively, and then dried by heating in an oven at 400°C. The alloy is configured according to the designed composition, wherein the mass percentage of element platinum is 26.5wt.%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, place the configured gold and platinum raw materials in a high-purity high-temperature resistant quartz crucible (crucible raw material adopts grade II quartz sand, SiO 2 Purity ≥ 99.98wt%), close the furnace door to evacuate, when the vacuum deg...

Embodiment 2

[0039] Embodiment 2 (common casting+rare earth lanthanum La)

[0040] In this embodiment, gold and platinum with a purity of 99.99wt.% are first purchased as raw materials, and the contents of impurity elements iron Fe, nickel Ni, and cobalt Co are all lower than 0.001wt.%. Under the assisted action of ultrasonic waves, the raw materials of gold and platinum blocks were washed three times with acetone solution and deionized water respectively, and then dried by heating in an oven at 400°C. The alloy is configured according to the designed composition, wherein the mass percentage content of element platinum is 26.5 wt.%, the mass percentage content of modified rare earth element lanthanum La is 0.5%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, place the configured gold and platinum raw materials in a high-purity high-temperature-resistant quartz crucible, close the furnace d...

Embodiment 3

[0042] Embodiment 3 (common casting+boron element)

[0043] In this embodiment, gold and platinum with a purity of 99.99wt.% are first purchased as raw materials, and the contents of impurity elements iron Fe, nickel Ni, and cobalt Co are all lower than 0.001wt.%. Under the assisted action of ultrasonic waves, the raw materials of gold and platinum blocks were washed three times with acetone solution and deionized water respectively, and then dried by heating in an oven at 400°C. The alloy is configured according to the designed composition, wherein the mass percentage of element platinum is 26.5 wt.%, the mass percentage content of modifying element boron B is 0.05%, and the balance element is gold. The vacuum induction melting furnace was heated and baked until the furnace temperature reached about 300°C. Then, place the configured gold and platinum raw materials in a high-purity high-temperature-resistant quartz crucible, close the furnace door to vacuumize, and when the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com