Adjustable lifting appliance for lifting formworks and using method thereof

An adjustable and spreader technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing manpower and material consumption, and the length of the transverse bridge remains unchanged, so as to save manpower and material consumption, easy to use, The effect of improving the utilization rate of the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

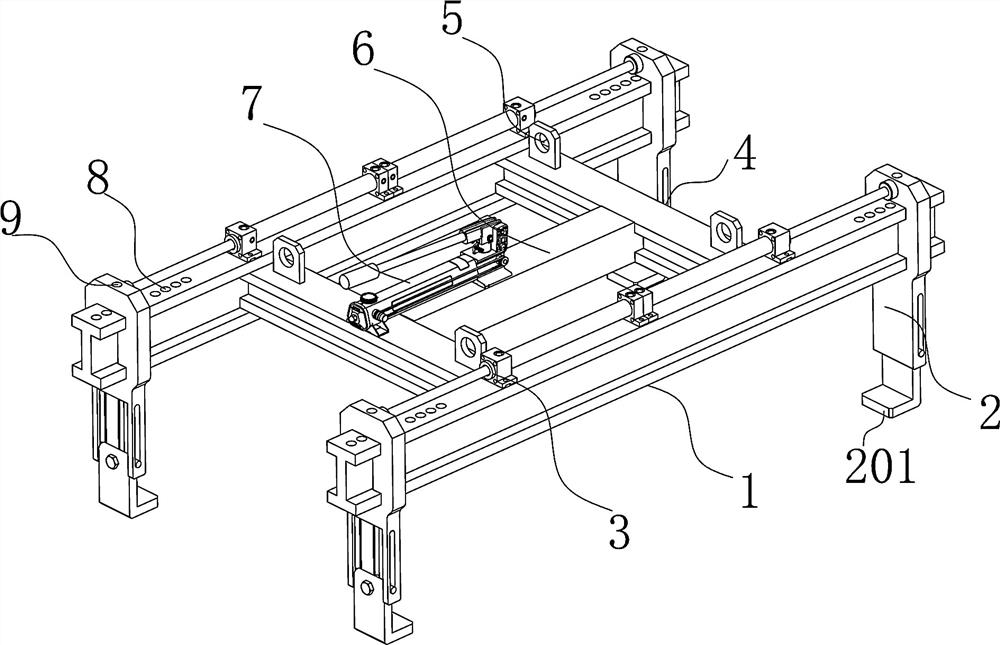

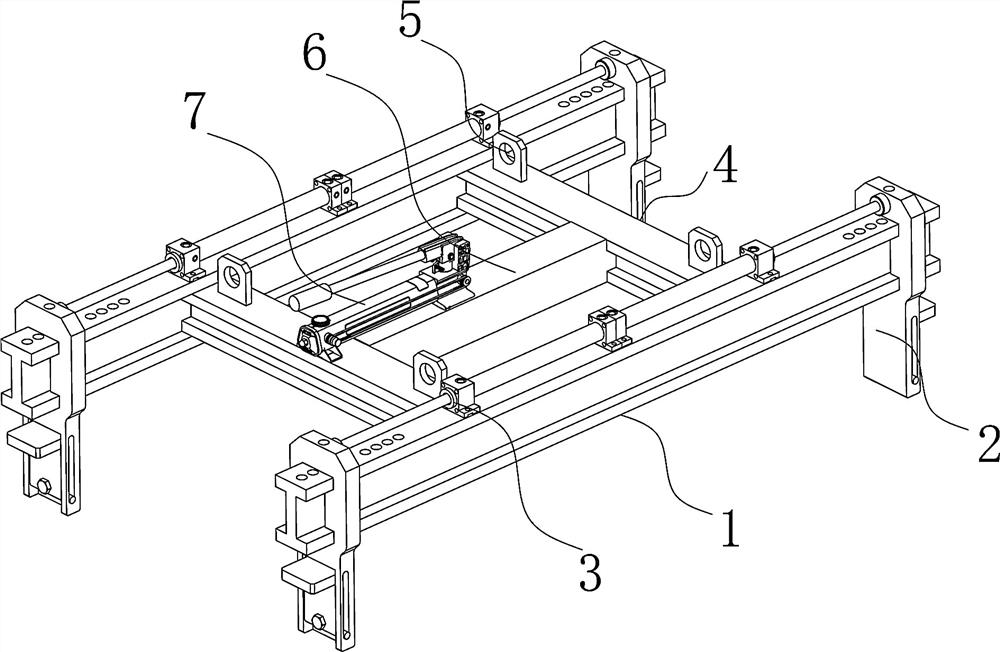

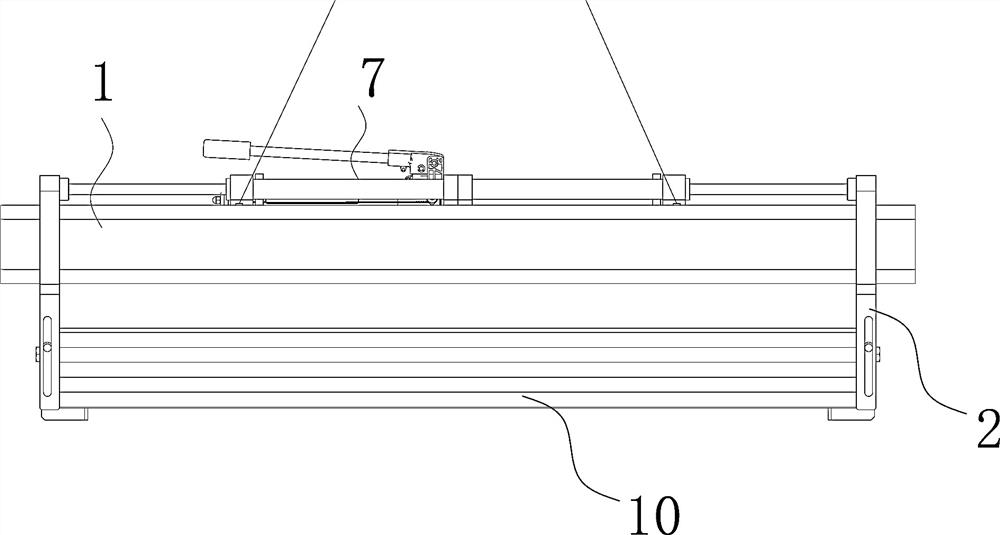

[0036] Such as Figure 1~8 As shown, an adjustable spreader for hoisting formwork includes at least two main girders 1, adjacent main girders 1 are connected by a plurality of support beams 4 to form a spreader frame, and the spreader frame is also equipped with A plurality of lifting lugs 5, splints 2 are provided at both ends of the main beam 1 of the spreader frame, the splints 2 are slidably connected with the main beam 1, and the splints 2 are locked on the main beam 1 by a locking device. Such as figure 1 In the shown structure, the splint 2 slides on the main beam 1, and the multiple splints 2 clamp the formwork 10, and then use the locking device to lock the position of the formwork 10, so as to clamp the formwork 10 laterally.

[0037] In the preferred solution, a plurality of hydraulic cylinders 3 are also provided on the main beam 1, and the telescopic rod of a single hydraulic cylinder 3 is connected to the splint 2, and a crossbeam 6 is passed between adjacent su...

Embodiment 2

[0046] Further illustrate in conjunction with embodiment 1, as Figure 1-8 As shown, the two main beams 1 are assembled through two supporting beams 4, and the two supporting beams 4 are connected through a crossbeam 6, and a hand pump 7 is installed on the crossbeam 6.

[0047] Hydraulic cylinders 3 are installed at both ends of the two main girders 1, the hydraulic pipes of the hydraulic cylinders 3 communicate with the hydraulic ports of the hand pump 7, and the oil return ports of the hydraulic cylinders 3 communicate with the oil return ports of the hand pump 7.

[0048] A splint 2 is installed at the end of the main beam 1 , and the sliding body 205 of the splint 2 is connected with the telescopic rod of the hydraulic cylinder 3 .

[0049] Utilize the crane to connect with the lifting lug 5 of the sling through the steel cable, lift the whole sling, make the sling rise into the air, hang the whole sling on the formwork to be hung, and open the reversing valve 702 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com