A hardware container surface polishing device and polishing method

A surface polishing and container technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of inability to accurately adjust the grinding mechanism and hardware container, poor polishing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

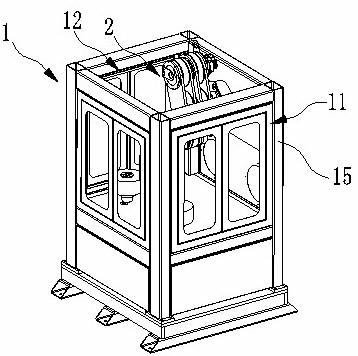

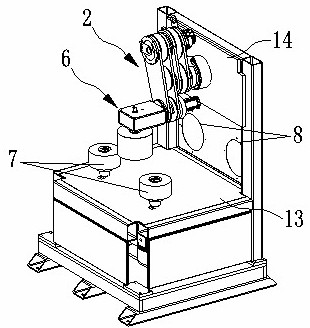

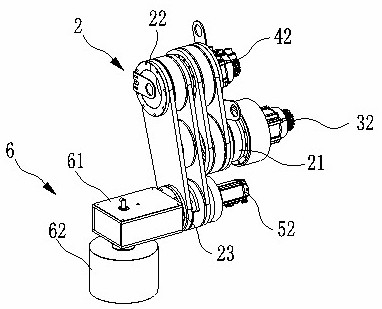

[0037] see Figure 1 to Figure 5 The hardware container surface polishing equipment related to the hardware container surface polishing device of the present invention includes a frame 1, a driving joint 2 and a grinding wheel 7; one end of the driving joint 2 is arranged on the frame 1, and the driving joint 2 has three Two rotating shafts connected in parallel in series, the hardware container (not shown in the figure) is arranged on the swing end of the driving joint 2, and the rotating shaft arranged at the end of the driving joint 2 controls the normal angle of contact between the hardware container and the grinding wheel 7, and the other two Three rotating shafts control the spatial position of the hardware container; the three rotating shafts are respectively the first rotating shaft 21, the second rotating shaft 22 and the third rotating shaft 23; the driving joint 2 includes three parallel first driving devices 32, second driving devices 42 and The third driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com