PCB surface thin layer quality analysis method

A quality analysis, thin-layer technology, applied in the analysis of materials, material analysis using wave/particle radiation, material analysis using the measurement of secondary emissions, etc., can solve time-consuming, complicated process, contact with chemical solutions, mechanical stress and other problems. Impurity pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for analyzing the quality of a PCB surface thin layer, comprising the following steps:

[0030] S1. Sample sampling: Use scissors, automatic sampler or nail scissors to take out the required measurement area from the PCB board, and use a high-pressure air gun to clean the surface. The test area needs to be as close to the edge of the sample as possible. The distance from the edge of the sample is less than 2mm;

[0031] S2. Gold spray treatment: the surface of the sample needs to be treated with conductivity, and the thickness of the gold spray is within 5 nanometers;

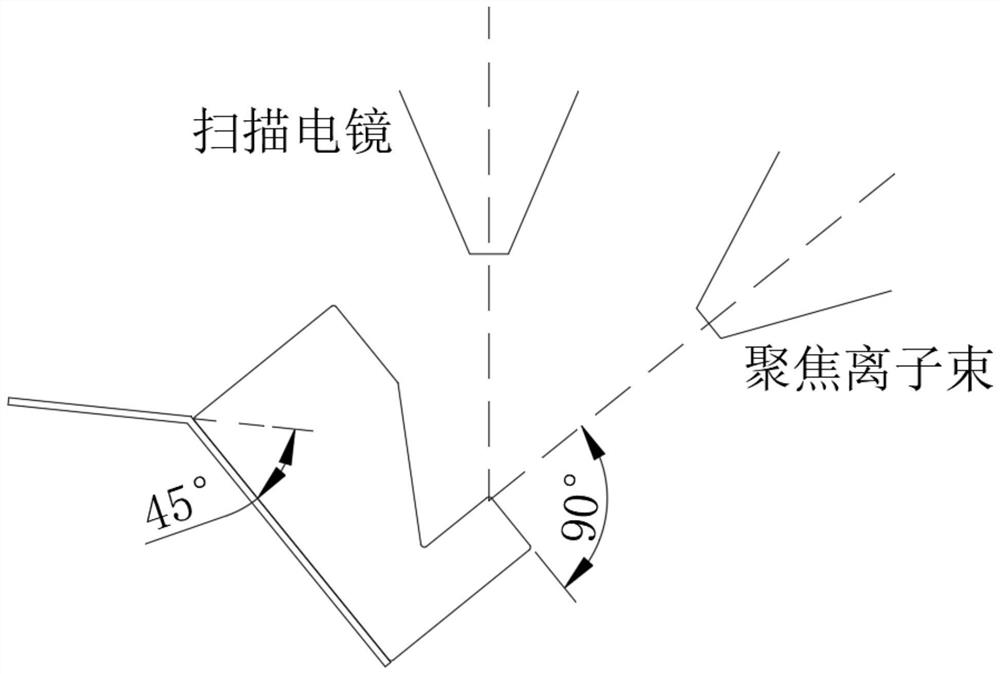

[0032] S3. Sample fixation and transfer: The sample to be tested should be firmly fixed on the metal sample stage, and ensure that the surface of the sample and the metal sample stage are well-conducted, and then install the sample stage with the sample on the inclined surface of the test platform. The area must face the highest point of the sample test platform, and the angle of the slope of t...

Embodiment 2

[0038] A method for analyzing the quality of a PCB surface thin layer, comprising the following steps:

[0039] S1. Sample sampling: Use scissors, automatic sampler or nail scissors to take out the required measurement area from the PCB board, and use a high-pressure air gun to clean the surface. The test area needs to be as close to the edge of the sample as possible. The distance from the edge of the sample is less than 2mm;

[0040] S2. Gold spray treatment: the surface of the sample needs to be treated with conductivity, and the thickness of the gold spray is within 5 nanometers;

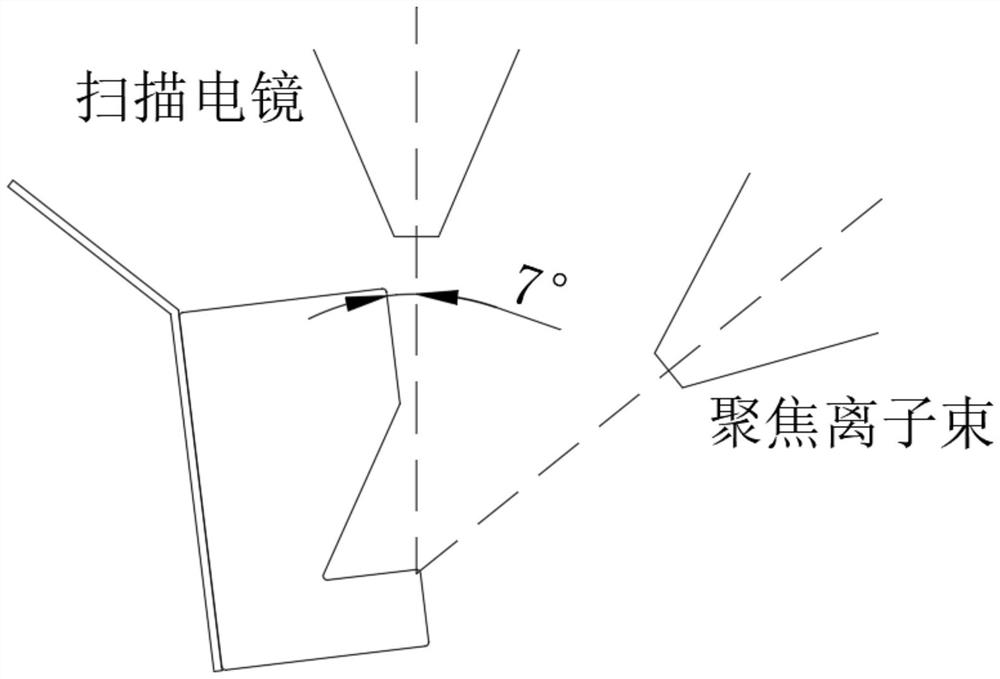

[0041] S3. Sample fixation and transfer: The sample to be tested should be firmly fixed on the metal sample stage, and ensure that the surface of the sample and the metal sample stage are well-conducted, and then install the sample stage with the sample on the inclined surface of the test platform. The area must face the highest point of the sample test platform, and the angle of the slope of t...

Embodiment 3

[0047] A method for analyzing the quality of a PCB surface thin layer, comprising the following steps:

[0048] S1. Sample sampling: Use scissors, automatic sampler or nail scissors to take out the required measurement area from the PCB board, and use a high-pressure air gun to clean the surface. The test area needs to be as close to the edge of the sample as possible. The distance from the edge of the sample is less than 2mm;

[0049] S2. Gold spray treatment: the surface of the sample needs to be treated with conductivity, and the thickness of the gold spray is within 5 nanometers;

[0050] S3. Sample fixation and transfer: The test sample should be firmly fixed on the metal sample stage, and ensure that the surface of the sample and the metal sample stage are well-conducted, and then install the sample stage with the sample on the inclined surface of the test platform. The area must face the highest point of the sample test platform, and the angle of the slope of the measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap