Safety device for pressure cooker with hole

A safety device and technology for pressure cookers, which are applied in the safety device and pressure cooker field to prevent excessive pressure in pressure cookers with holes, can solve problems such as poor total cost price and impact on total production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

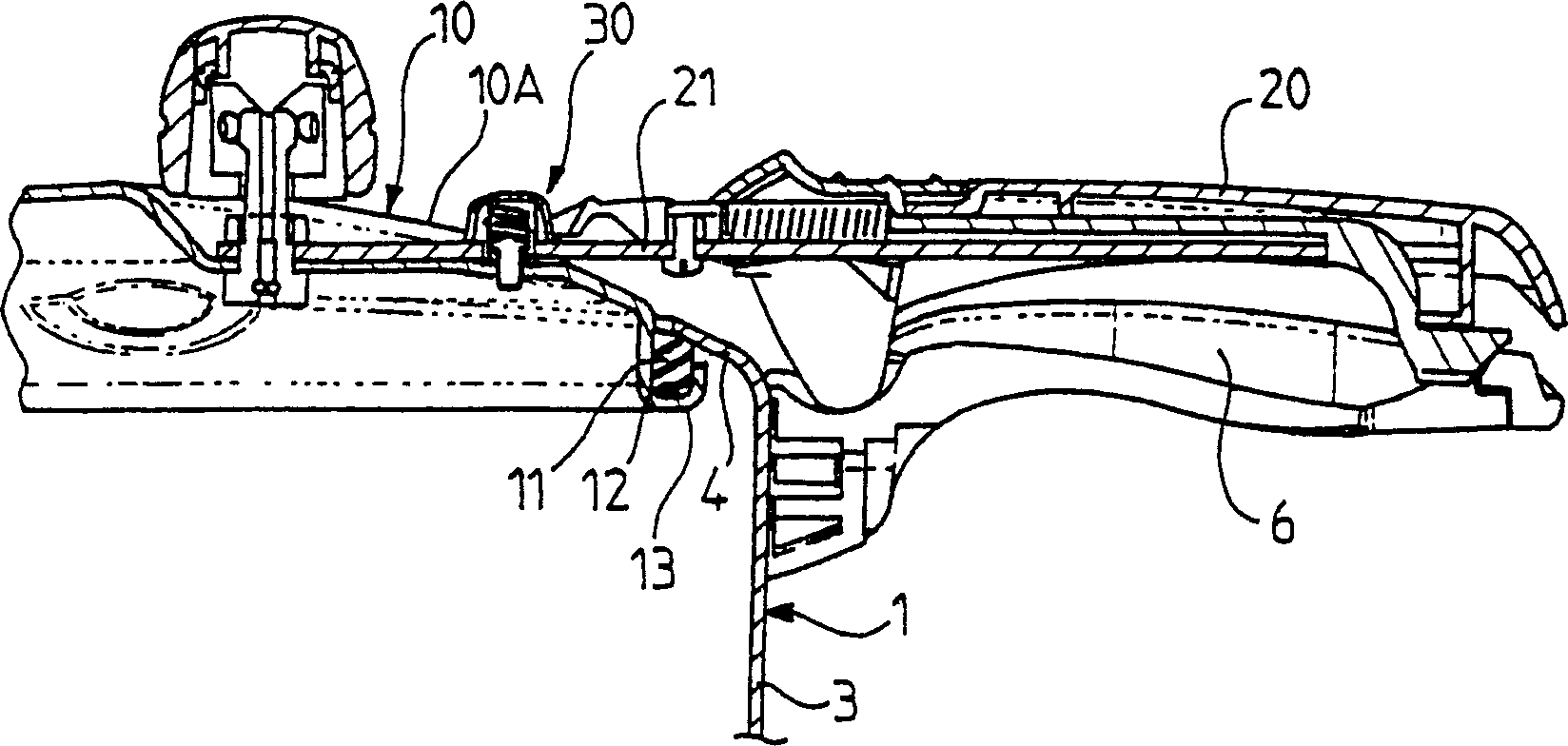

[0020] figure 1 Represents a perforated pressure cooker which, when the pressure cooker is a perforated pressure cooker, comprises a pot body 1 made of metal with a bottom (not shown in the figure), from which rises substantially vertical side walls 3 , the side wall 3 is covered by a concave edge 4 extending over the entire periphery of the pot body 1, forming a substantially elliptical opening.

[0021] In conventional form, the pot body 1 has a radially projecting handle 6 secured thereto by any suitable means, for example by bolts passing through the side wall 3 .

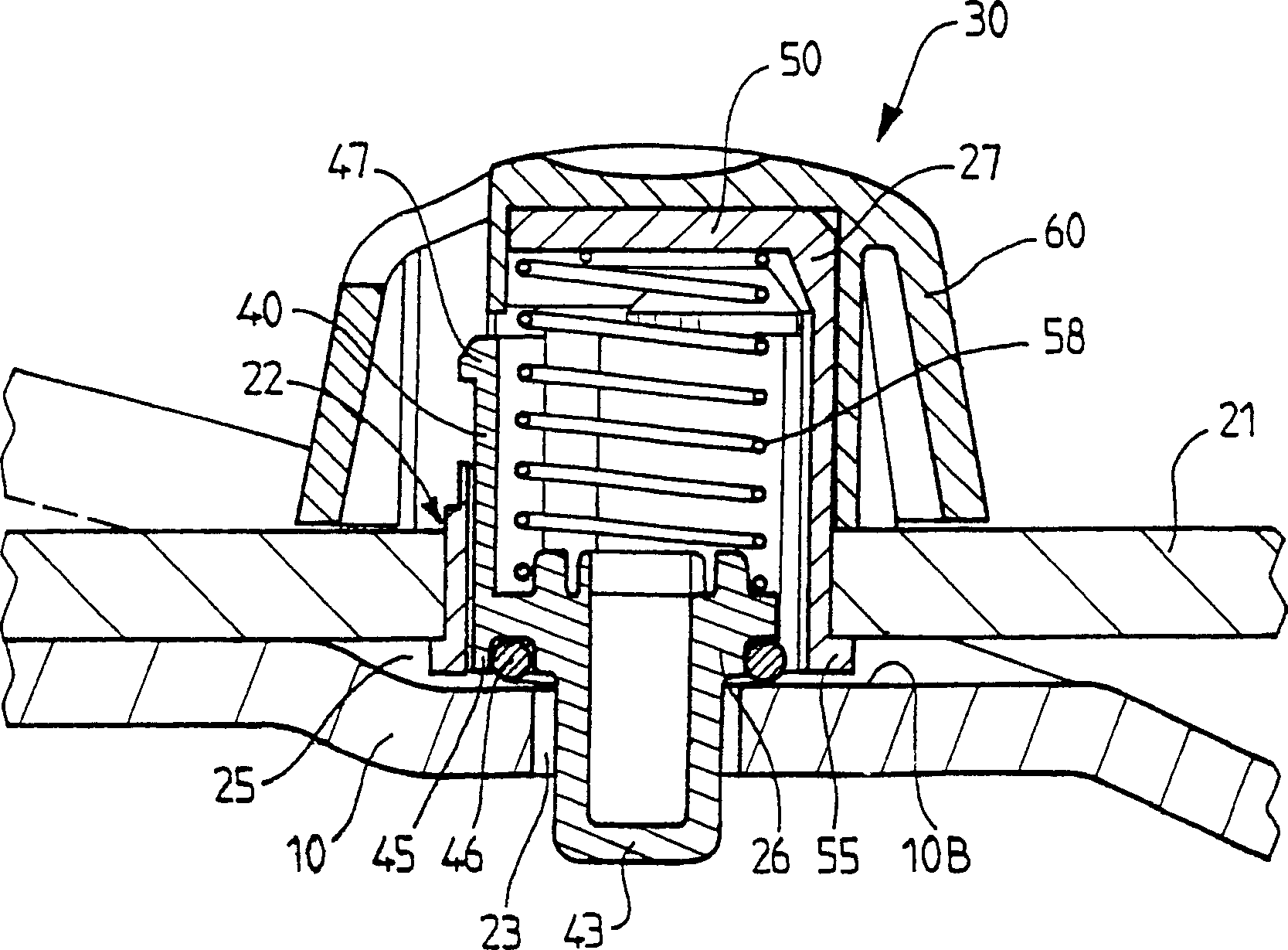

[0022] The cooking utensil of the invention also has a pot lid 10 of likewise substantially elliptical shape with a convex central portion 10A, the pot lid 10 being designed to be inserted into the opening of the pressure cooker 1 so that by mounting on said pot lid 10 The sealing ring in the circumferential groove of the pressure cooker lid is airtightly closed, and the groove is formed by the edge 13 turned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com