Pressure cooker having built-in cover

A built-in pressure cooker technology, applied in the field of pressure cooker, can solve the problems of troublesome processing, high processing cost, large size of pot cover, etc., and achieve the effect of simple structure, convenient opening and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

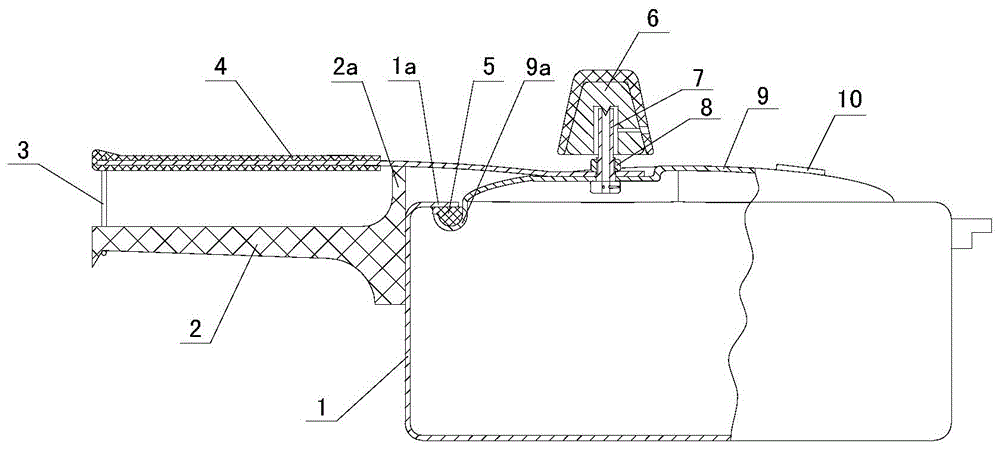

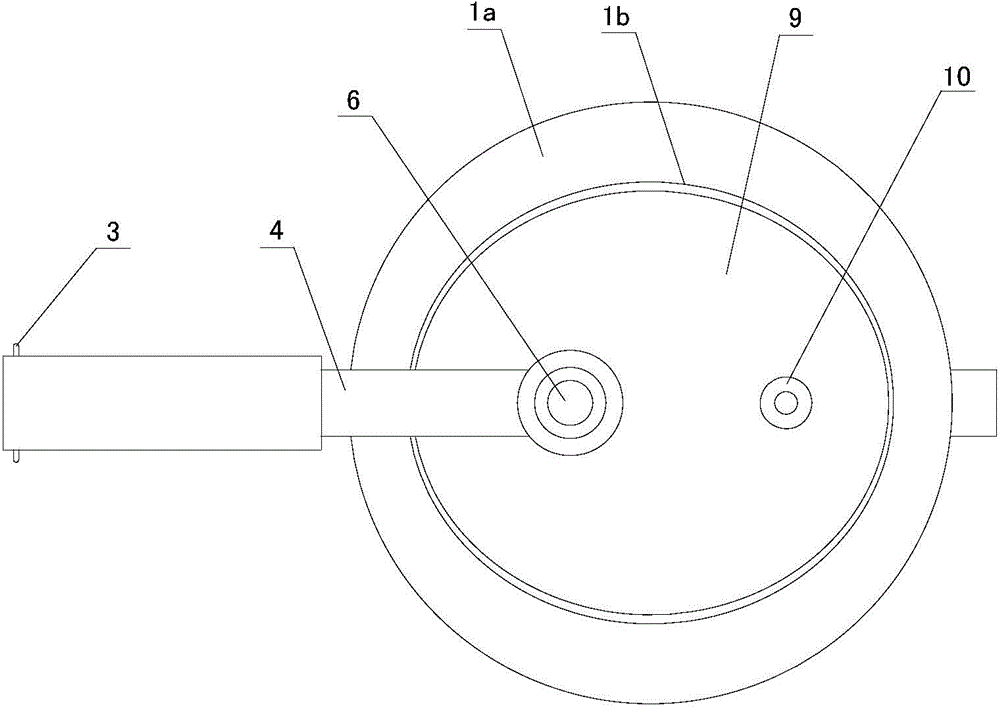

[0010] see figure 1 , figure 2

[0011] The pot lid built-in pressure cooker provided by the present invention has a pot body 1 and a pot cover 9, the pot body 1 is equipped with a lower handle 2, the pot cover 9 is equipped with an upper handle 4, an exhaust nozzle 7 and a safety valve 10, and the exhaust nozzle 7 is equipped with There is a bonnet 6 matched with it, and the upper handle 4 requires a certain elastic deformation capacity. The upper port of the pot body 1 has a flanging 1a bent inwardly, the edge of the flanging 1a forms an oval pot mouth 1b, the pot cover 9 is oval, and the edge of the pot cover 9 has a flange that cooperates with the flanging 1a. Back-up ring 9a, sealing gasket 5 is housed on the outer surface of back-up ring 9a, lower handle 2 has protruding support platform 2a near the position of pot body, and last handle 4 extends to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com