Sound level meter calibrating device rotary table

A technology for verification devices and sound level meters, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of low verification efficiency, high cut-off frequency, and short sound-absorbing space of the anechoic box, so as to improve the verification Work efficiency, shorten the test time, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

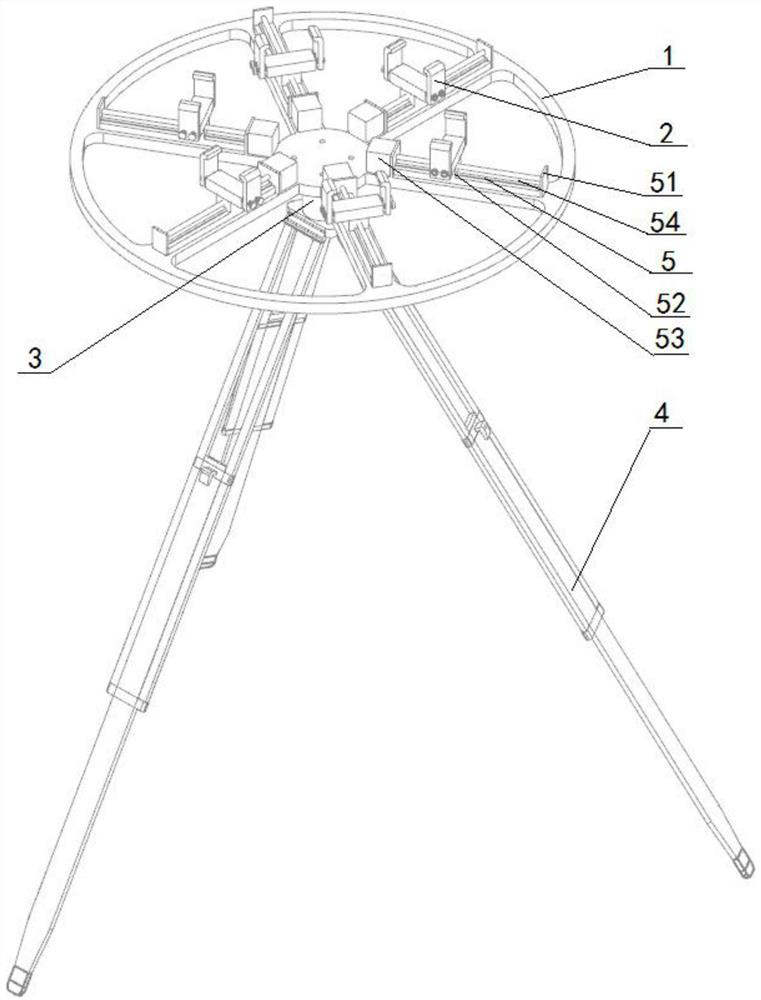

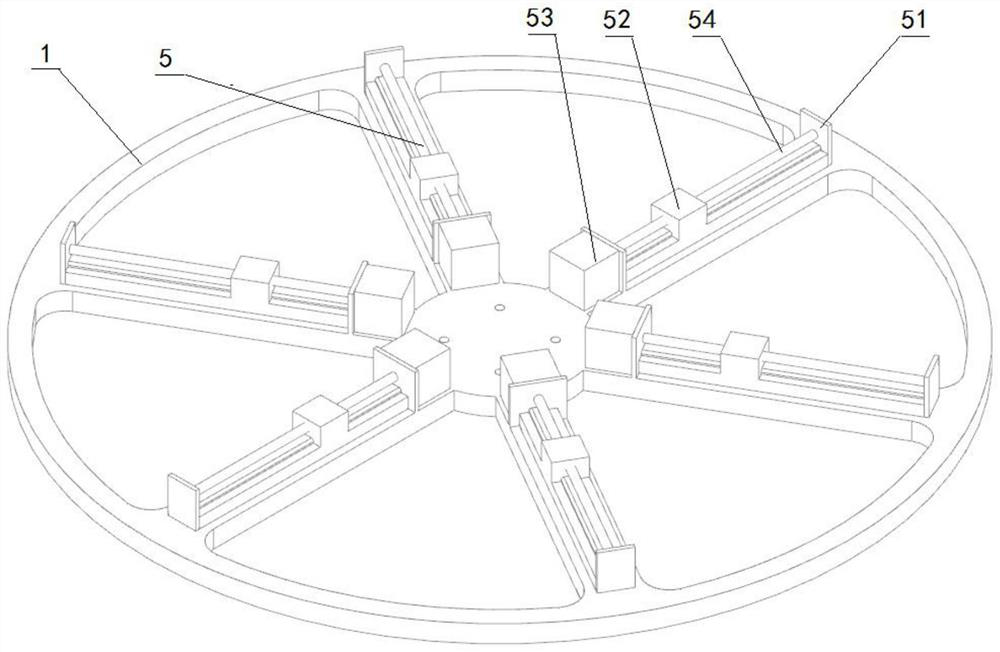

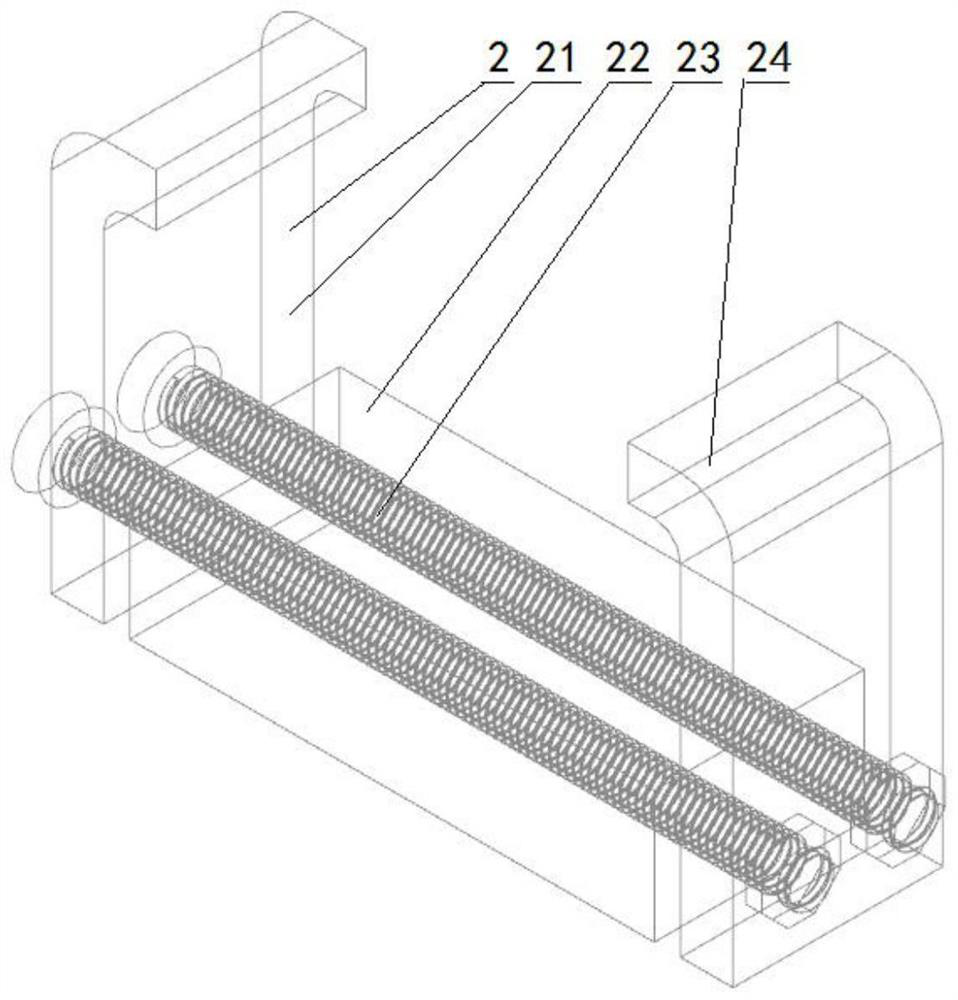

[0039] A sound level meter verification device turntable, such as figure 1 As shown, its structure specifically includes a support device 4 for providing overall support, and a drive assembly 3 for providing power is provided on the upper side of the support device 4. The output of the drive assembly 3 is connected to the turntable 1, and the turntable 1 is arranged on On the upper side of the drive assembly 3, the drive assembly 3 is used to drive the turntable 1 to achieve circumferential angle adjustment. There are multiple fixtures 2 evenly distributed on the turntable 1. The fixtures 2 are used to respectively clamp the standard microphone and multiple tested instruments. 2 can be adjusted along the radial direction of the turntable 1. The turntable 1 is also provided with a detection device for collecting the rotation angle of the turntable 1 . There is a controller on the drive assembly 3 , and the controller is electrically connected to the detection device and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com