A broach mechanism for tool grinder spindle

A tool grinding machine and spindle technology, applied in the direction of manufacturing tools, grinding machine parts, other manufacturing equipment/tools, etc., can solve the problems of lower production efficiency, low safety, limited applicable tools, etc., and achieve easy installation and disassembly , good stopping effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

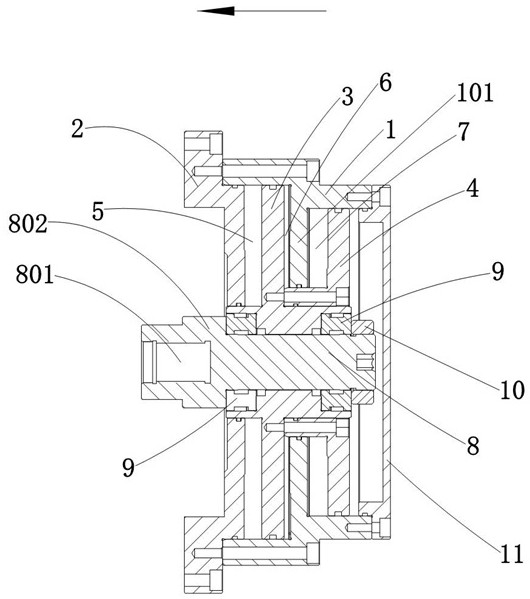

[0028]A broach mechanism for a tool grinder spindle, comprising a cylinder body 1, a cylinder body support sleeve 2 fastened to the cylinder body 1, a first piston 3 arranged inside the cylinder body 1, and a second piston 3 arranged inside the cylinder body 1. Piston 4, mandrel 8, the second piston 4 is sleeved on the first piston 3, and is tightly connected with the first piston 3, and the first piston 3 forms a first non-communicating first piston 3 inside the cylinder 1 Piston chamber 5 and second piston chamber 6, the second piston 4 forms a third piston chamber 7 inside the cylinder 1, the third piston chamber 7 and the first piston chamber 5 are not communicated with each other, the mandrel 8 Coaxially penetrates in the first piston 3, and the mandrel 8 can move axially with the first piston 3, and the mandrel 8 is rotatably connected with the first piston 3; the cylinder support sleeve 2 is installed on the headstock On the body, one end of the mandrel 8 is provided wi...

Embodiment 2

[0033] A broach mechanism for a tool grinder spindle, comprising a cylinder body 1, a cylinder body support sleeve 2 fastened to the cylinder body 1, a first piston 3 arranged inside the cylinder body 1, and a second piston 3 arranged inside the cylinder body 1. Piston 4, mandrel 8, the second piston 4 is sleeved on the first piston 3, and is tightly connected with the first piston 3, and the first piston 3 forms a first non-communicating first piston 3 inside the cylinder 1 The piston chamber 5 and the second piston chamber 6, the second piston 4 forms a third piston chamber 7 inside the cylinder 1, the third piston chamber 7 and the first piston chamber 5 communicate with each other, and the mandrel 8 is the same as the The shaft is penetrated in the first piston 3, and the mandrel 8 can move axially with the first piston 3, and the mandrel 8 is rotatably connected with the first piston 3; the cylinder support sleeve 2 is installed on the main shaft case On the top, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com