TOM film suitable for automobile exterior decoration and preparation method of TOM film

A technology for exterior decoration and automobile, applied in the field of membrane materials, it can solve the problems of harsh, TOM membrane can not adapt to the test standard of automobile exterior decoration and the use environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

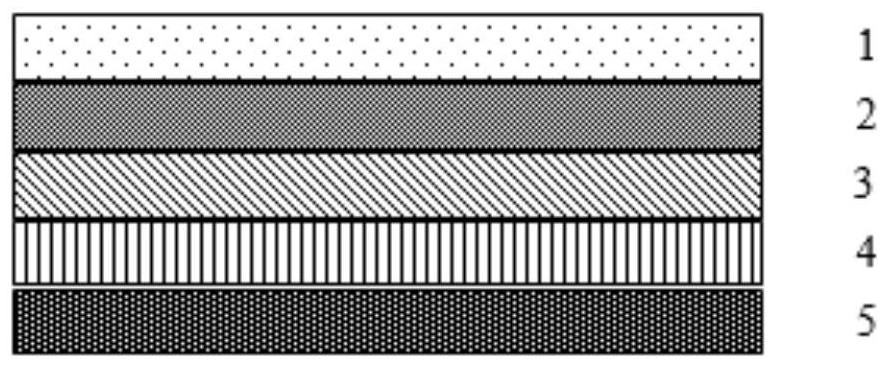

[0032] The present embodiment provides a kind of TOM film that is suitable for automobile exterior decoration, and it has such as figure 1 structure shown. It includes a surface protection layer 1, a decoration layer 2, an adhesive layer 3, a substrate 4, and an adhesive layer 5 arranged sequentially from top to bottom.

[0033] The preparation method of the above-mentioned TOM film suitable for automobile exterior decoration may further comprise the steps:

[0034] (1) Use gravure printing to print ink on the surface protection layer PVDF / PMMA co-extruded film as a decorative layer; wherein the thickness of the PVDF / PMMA co-extruded film is 30 μm;

[0035] (2) Install an adhesive layer on the decorative layer by using dimple coating, etc., and remove the organic solvent in the adhesive layer by heat drying; the thickness of the adhesive layer after drying is 8 μm;

[0036] (3) Composite the base material ABS and the adhesive layer by thermal composite rollers; wherein the A...

Embodiment 2

[0040] The present embodiment provides a kind of TOM film that is suitable for automobile exterior decoration, and it obtains through the following steps:

[0041] (1) Use gravure printing to print ink on the surface protection layer PVDF / PMMA co-extruded film as a decorative layer; wherein the thickness of the PVDF / PMMA co-extruded film is 30 μm;

[0042] (2) Install an adhesive layer on the decorative layer by using dimple coating, etc., and remove the organic solvent in the adhesive layer by heat drying; the thickness of the adhesive layer after drying is 8 μm;

[0043] (3) Composite the substrate PC and the adhesive layer by thermal composite rollers; wherein the PC thickness is 400 μm;

[0044] (4) Set the adhesive layer on the back of the substrate PC, and remove the organic solvent in the adhesive layer by heat drying; the thickness of the adhesive layer after drying is 15 μm;

[0045] (5) ripen the finished product obtained in step (4), roll it up, and cut it.

Embodiment 3

[0047] The present embodiment provides a kind of TOM film that is suitable for automobile exterior decoration, and it obtains through the following steps:

[0048] (1) Use gravure printing to print ink on the surface protection layer PVDF / PMMA co-extruded film as a decorative layer; wherein the thickness of the PVDF / PMMA co-extruded film is 50 μm;

[0049] (2) Install an adhesive layer on the decorative layer by using dimple coating, etc., and remove the organic solvent in the adhesive layer by heat drying; the thickness of the adhesive layer after drying is 8 μm;

[0050] (3) Composite the substrate ABS and the adhesive layer through thermal composite rollers; wherein the ABS thickness is 400 μm;

[0051] (4) Set a back adhesive layer on the back of the substrate ABS, and remove the organic solvent in the adhesive layer by heat drying; the thickness of the adhesive layer after drying is 15 μm;

[0052] (5) ripen the finished product obtained in step (4), roll it up, and cut it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com