Control method and control device of high-speed brushless direct current motor

A brushed DC motor and control method technology, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of high cost, complex hardware circuit, large sensor volume, etc., to achieve increased amplitude and easy detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be disclosed in the following diagrams. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are not necessary.

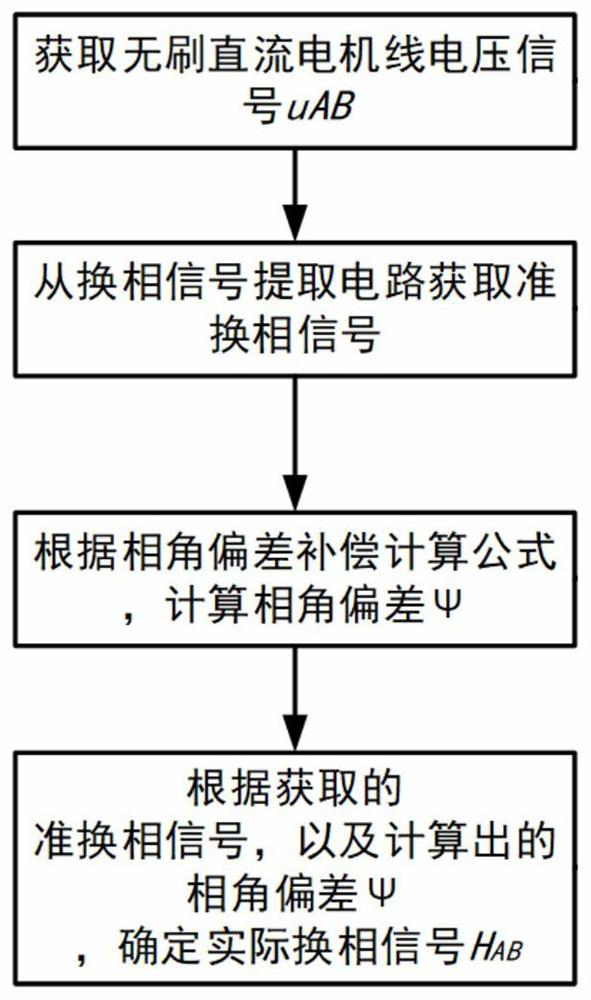

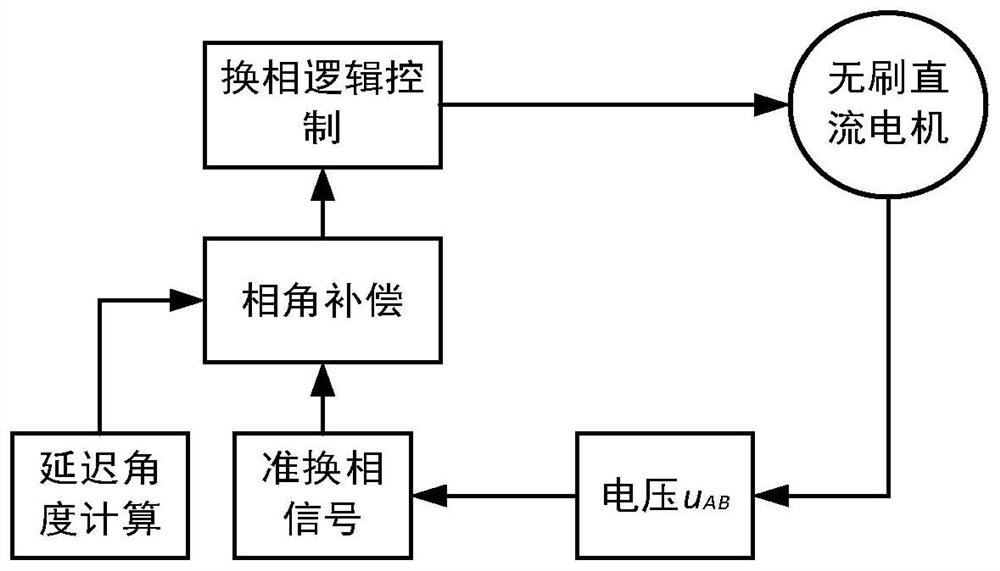

[0029] Such as figure 1 As shown, the flow chart of a high-speed brushless DC motor control method is proposed for the present invention, and the specific design includes:

[0030] Step S1: Obtain the line voltage signal u of the brushless DC motor AB ;

[0031] Step S2: Obtain quasi-commutation signal H from the commutation signal extraction circuit AB ";

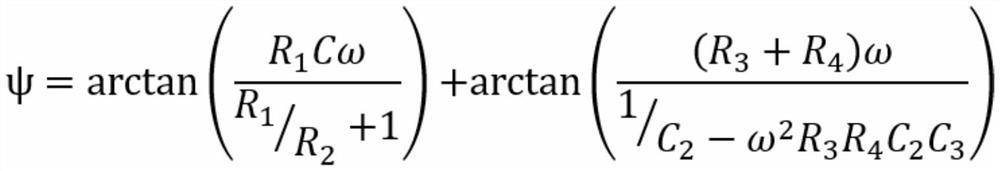

[0032] Step S3: The commutation signal extraction circuit in the step S2 reasonably designs the parameters of its resistance and capacitance according to the observed waveform diagram of the quasi-commutation signal, so as to filter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap