Reusable pull rod type quick locking device

A technology of locking device and pull rod, applied in the direction of workpiece clamping device, manufacturing tools, etc., to achieve strong adaptability, improve fastening efficiency, and reduce the difficulty of locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

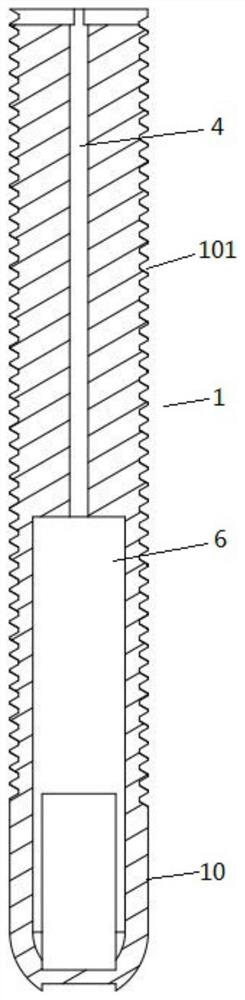

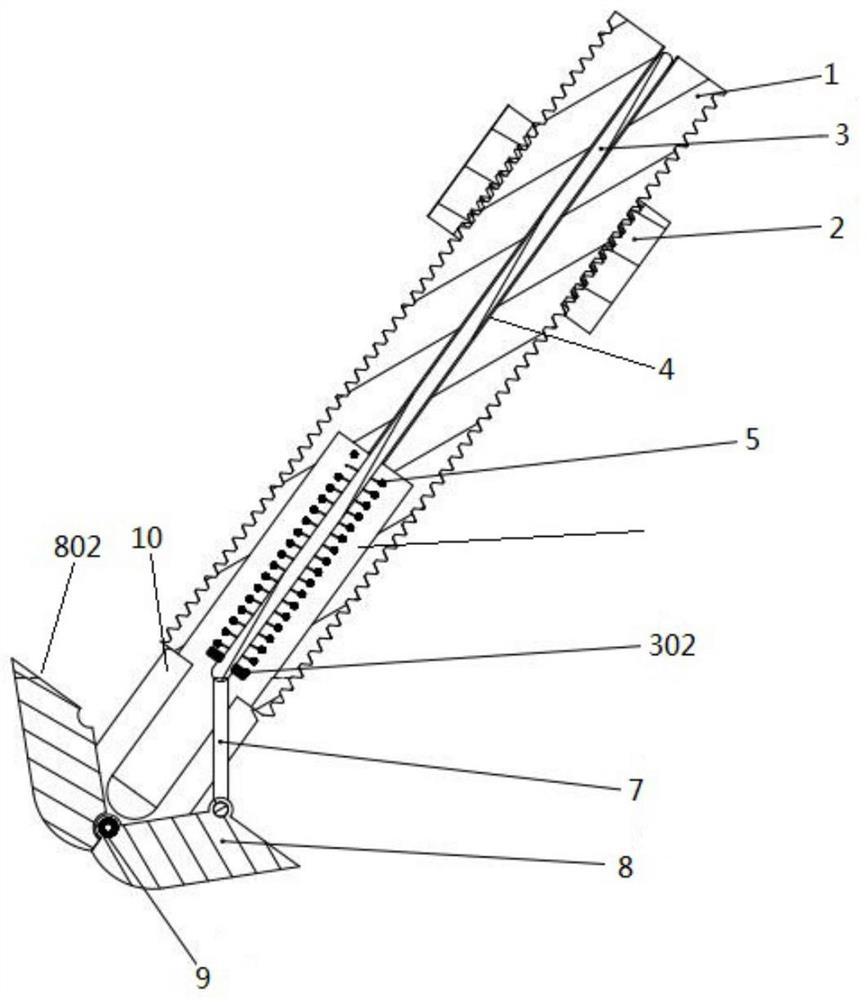

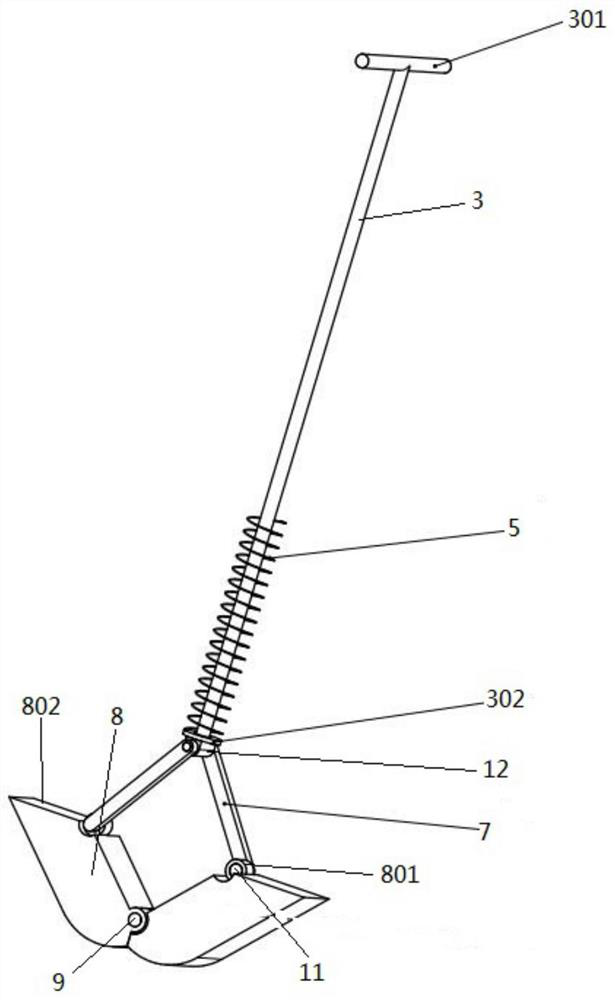

[0027] A reusable pull rod type quick locking device, comprising a stud 1, the stud 1 has a cylindrical structure as a whole, such as figure 1 and figure 2 As shown, the outer surface of the stud 1 is provided with an external thread 101, and the external thread 101 is mainly used for connecting the lock nut 2, that is, the lock nut 2 is sleeved on the stud 1 and is threaded. In practical applications, along the axial direction of the stud 1, the distribution length of the external thread 101 is not only related to the moving distance of the lock nut 2, but also can be determined according to the properties of the through holes on the locked sealing member (not shown). To design, for example, when the threaded connection between the stud 1 and the through hole on the locked sealing member is required, the distribution length of the external thread 101 of the stud 1 can be extended, and even the outer surface of the stud 1 can be extended. All are wrapped by external threads ...

Embodiment 2

[0035] This embodiment is the same as Embodiment 1, the difference is that the end surface of the stud 1 opposite to the brake rod 301 is provided with a brake rod groove 102 for accommodating the brake rod 301, as Figure 4 As shown, the length of the brake rod 301 is greater than the length of the brake rod slot 102 .

Embodiment 3

[0037] This embodiment is the same as Embodiment 1, the difference is that the rod through hole 4 is threadedly connected with the locking rod 3, and the locking rod 3 is rotationally connected with the bushing 12 (not shown in the figure out). In this embodiment, this embodiment mainly considers that during the process of placing the locking device in the through hole of the locking sealing member, it is necessary to keep the pull rod lifted, which may cause inconvenience to the locking operation. For this reason, through The threaded connection between the locking rod 3 and the rod through hole 4 can accurately adjust the lifting distance of the locking rod 3, even if the locking rod 3 is not pulled, the lifting state can be maintained to facilitate the locking device Perform related operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com