Improvements relating to electrically heated vessels

A technology for electric heating, containers, used in applications, cooking utensils, household utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

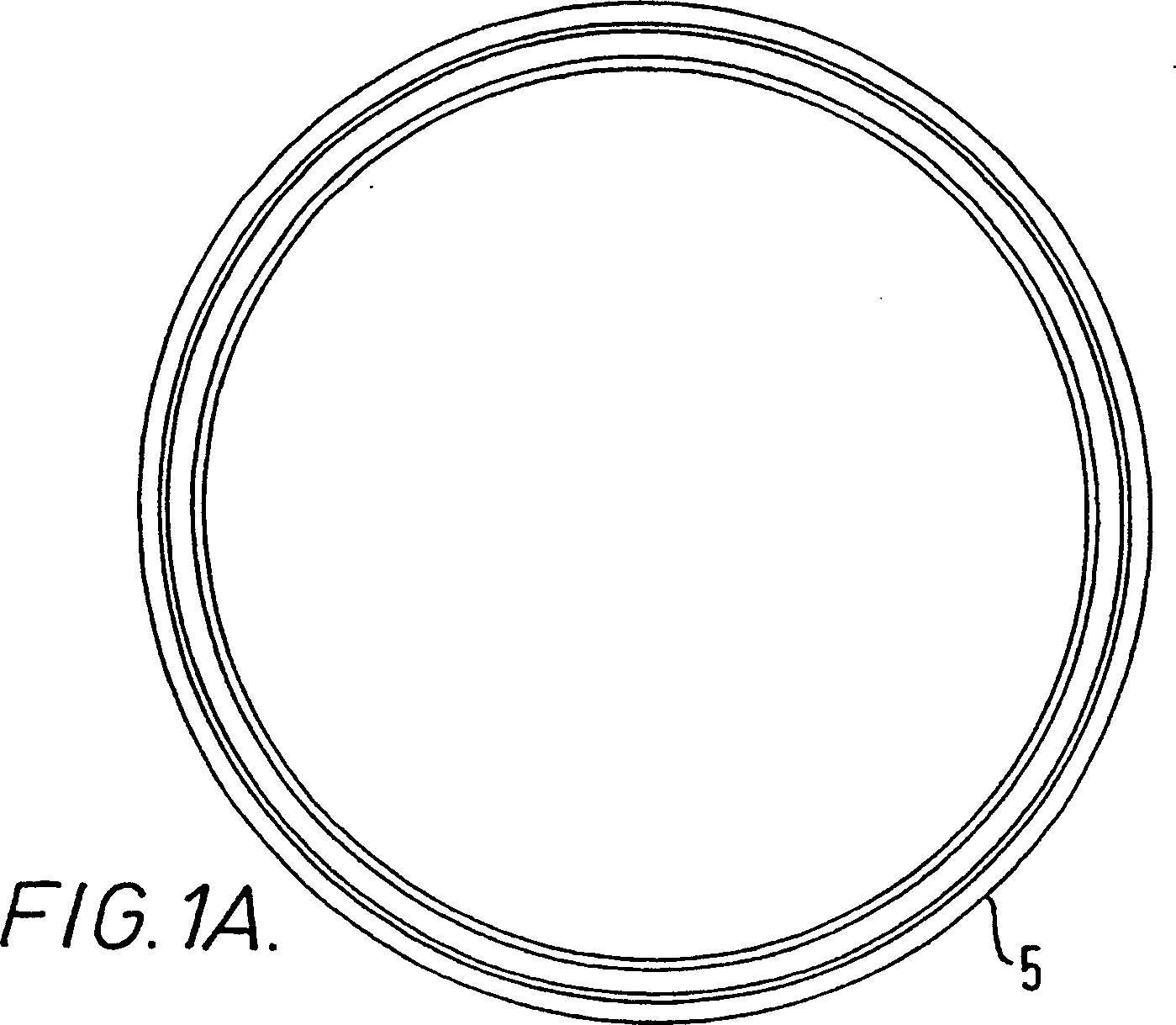

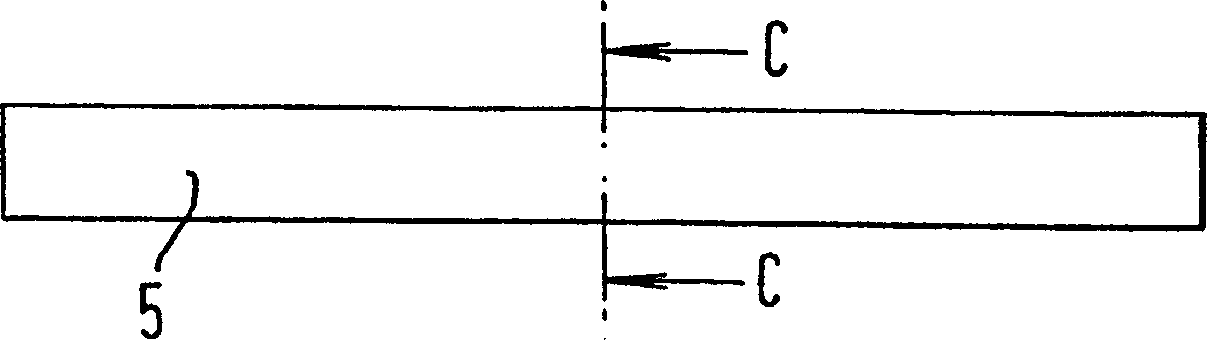

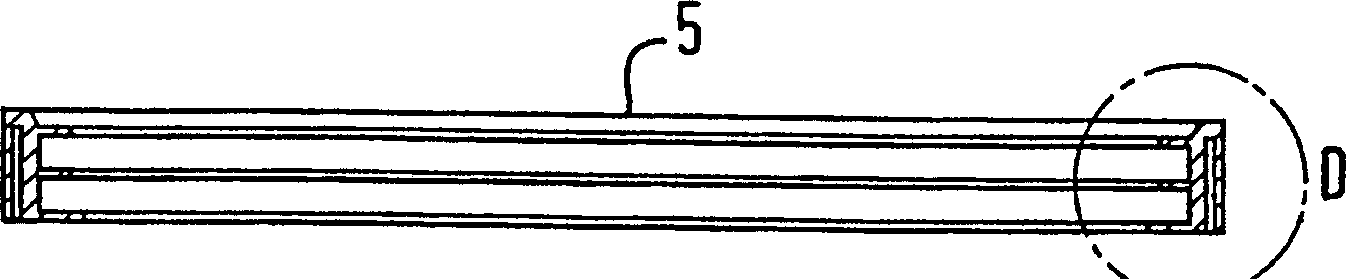

[0018] First with reference to the exploded view of Fig. 2, it is shown in the figure that the model blow molding of the opening is generally a cylindrical glass container main body 1, an integral pouring outlet 2 is housed on its upper edge 3, and on its other One end (bottom end) is provided with a reduced diameter neck portion 4 . An O-shaped elastomeric seal 5, shown more clearly in the several views of FIG. 1 and described in more detail hereinafter, is adapted to seal with the outer surface 6 of the necked portion 4 of the container body 1. join. The seal 5 is also adapted to forcibly engage with the upwardly bent flange part 7 of the schematically shown plate heating element 8 and to seal the flange part when the heating element 8 is fitted to the base of the vessel body 1 as described hereinafter. The gap between the inner surface of 7 and the outer surface 6 of the necked body part 4. Finally, Fig. 2 also shows a base 9 provided with internal ribs 10 for maintaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com