Automatic hob head in shield tunneling machine

A hob and shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems affecting tool change efficiency, consumption, and large physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

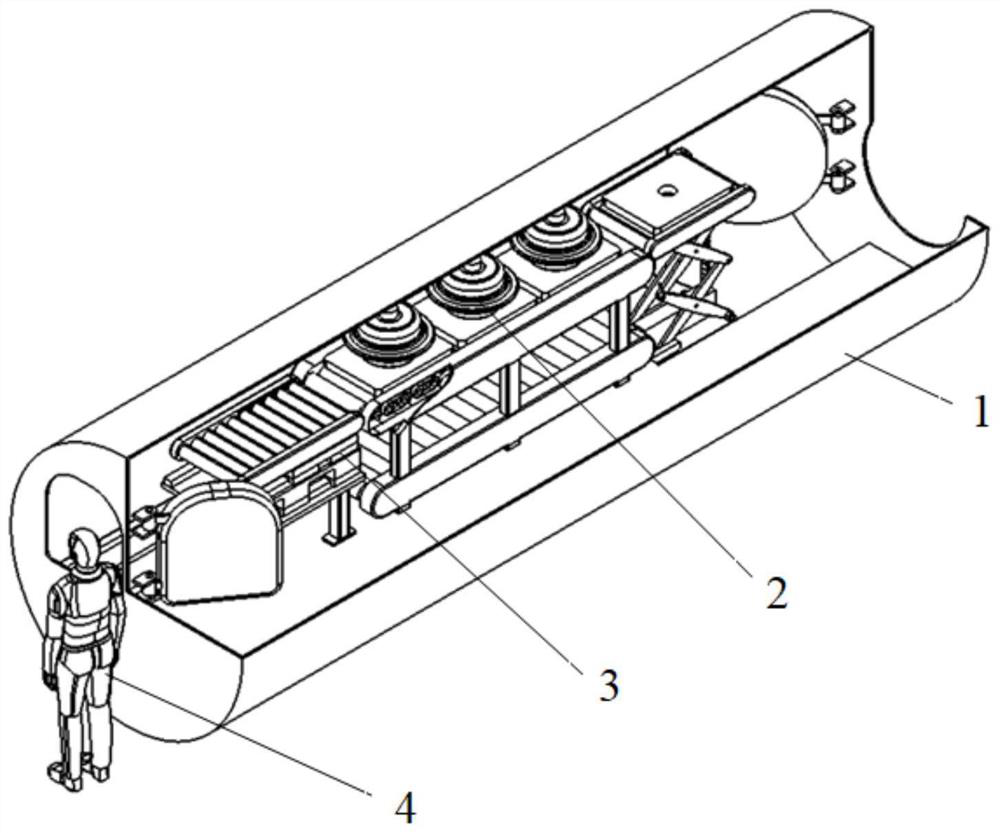

[0027] The invention provides an automatic hob frame inside a shield machine, such as figure 1 As shown, it includes a cabin body 1 and an automatic knife rest 3. The automatic tool holder 3 is installed inside the cabin body 1, the cabin body 1 has a columnar structure, and the cabin body 1 is connected with the shield machine body by screws.

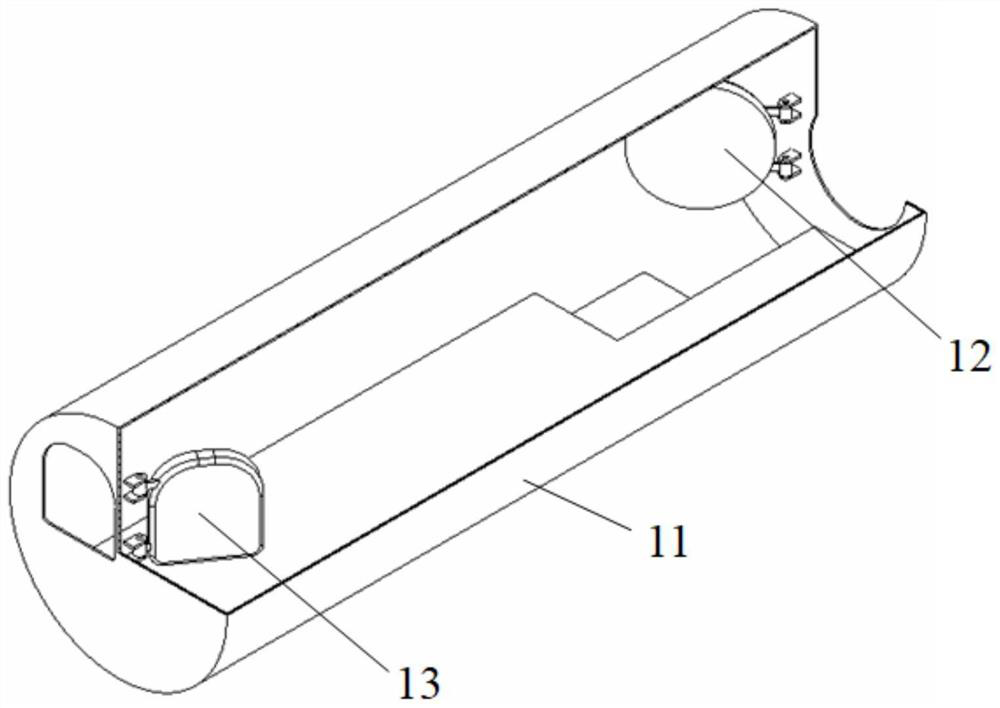

[0028] Such as figure 2 As shown, the cabin body 1 is made up of housing 11, front hatch door 12 and rear hatch door 13, and front hatch door 12 and rear hatch door 13 are all arranged on the housing 11, and front hatch door 12 is close to mud tank (or cutter head ), the rear hatch 13 is opposite to the front hatch 12, and the housing 11 is formed by roll bending welding of high-strength steel plates. The front hatch 12 and the rear hatch 13 are all in an open state outwardly. When it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com