A glass cutting machine tool holder mechanism

A cutting machine and knife holder technology, applied in the direction of glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of weak strength and low glass cutting efficiency, and achieve the effect of efficient oil change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

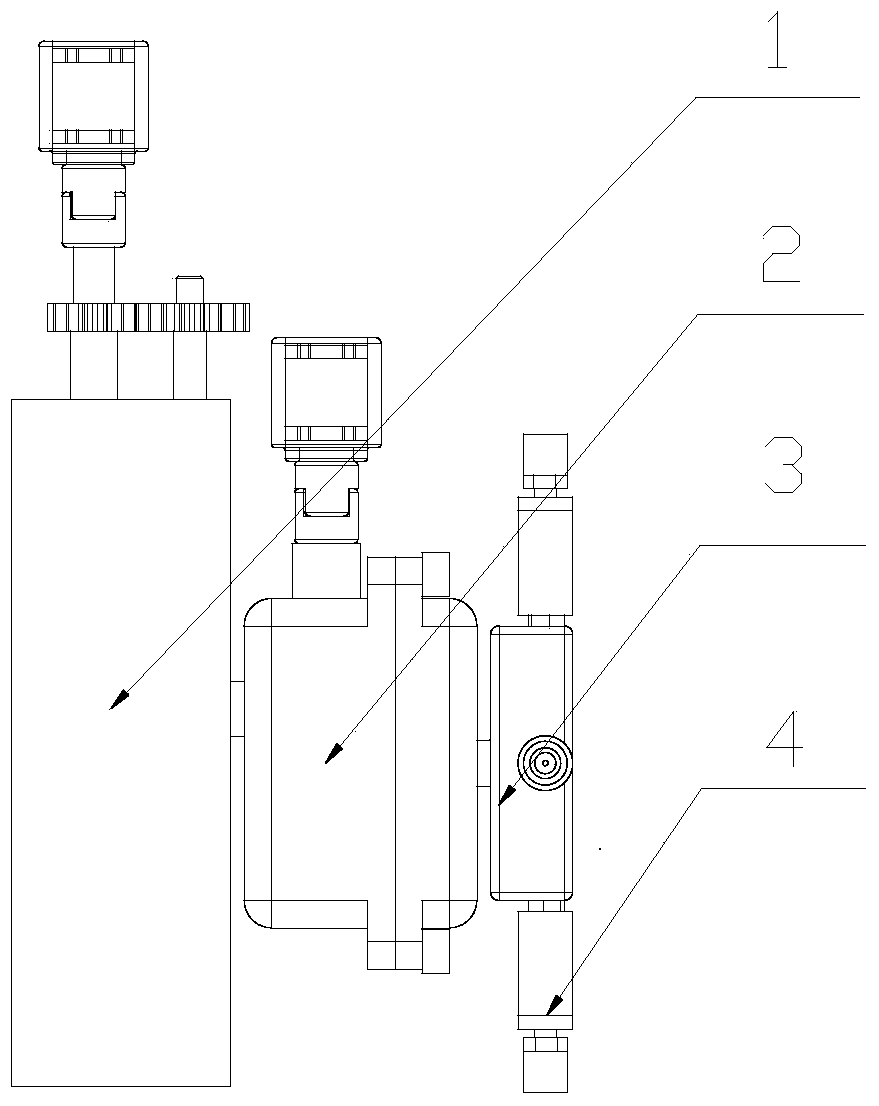

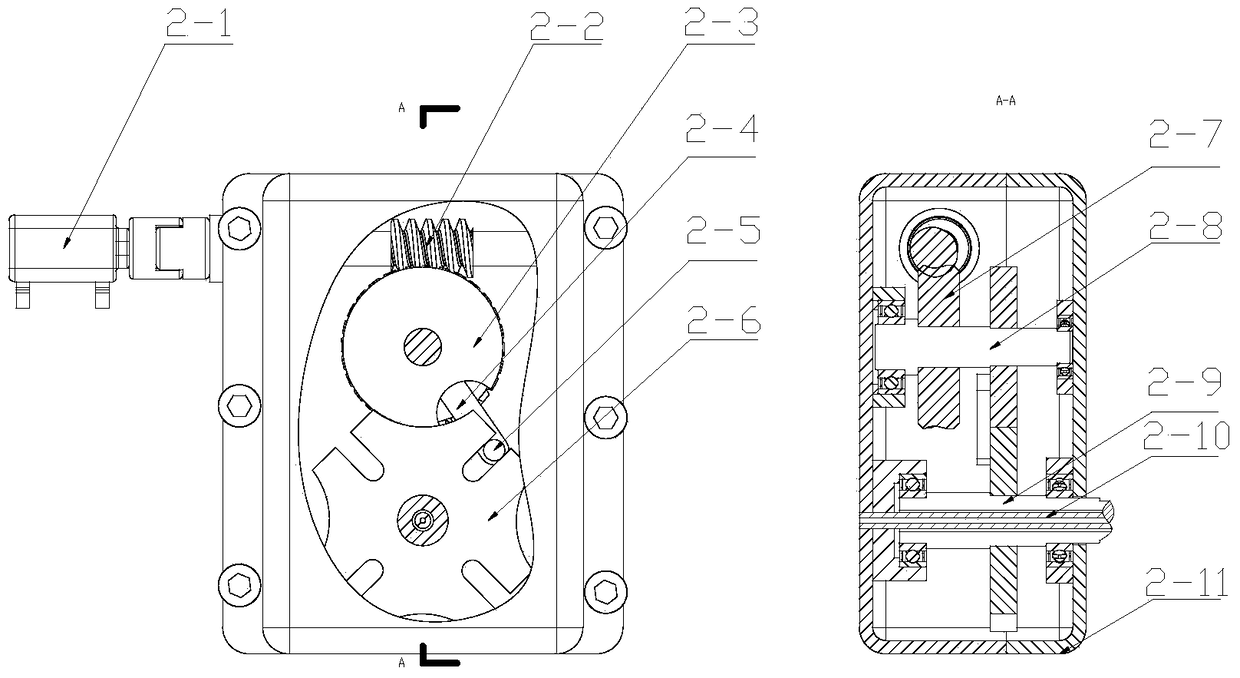

[0021] Embodiment 1 A knife holder mechanism for a glass cutting machine, including a rotatable knife holder 3, a fixed knife seat 2 for driving the rotatable knife holder 3 to rotate, and a tool clamping device 4, along the outer surface of the rotatable knife holder 3. Its rotation direction is provided with more than two tool clamping devices 4, and the fixed tool seat 2 includes a first servo motor 2-1, a worm screw 2-2, a worm wheel 2-7, a transmission shaft 2-8, and a notch disc 2 -3. The rotating arm 2-4, the sheave 2-6 and the rotary hollow main shaft 2-9, the first servo motor 2-1 is connected with the worm 2-2, and the worm 2-2 is in phase with the worm wheel 2-7 meshing, the worm wheel 2-7 and the notch disc 2-3 are fixed on the transmission shaft 2-8, the notch disc 2-3 is engaged with the sheave 2-6 and drives the sheave 2-6 to rotate, Preferably, the notched disc 2-3 is connected to the cylindrical pin 2-5 through the rotating arm 2-4, and the slots of the sheave...

Embodiment 2

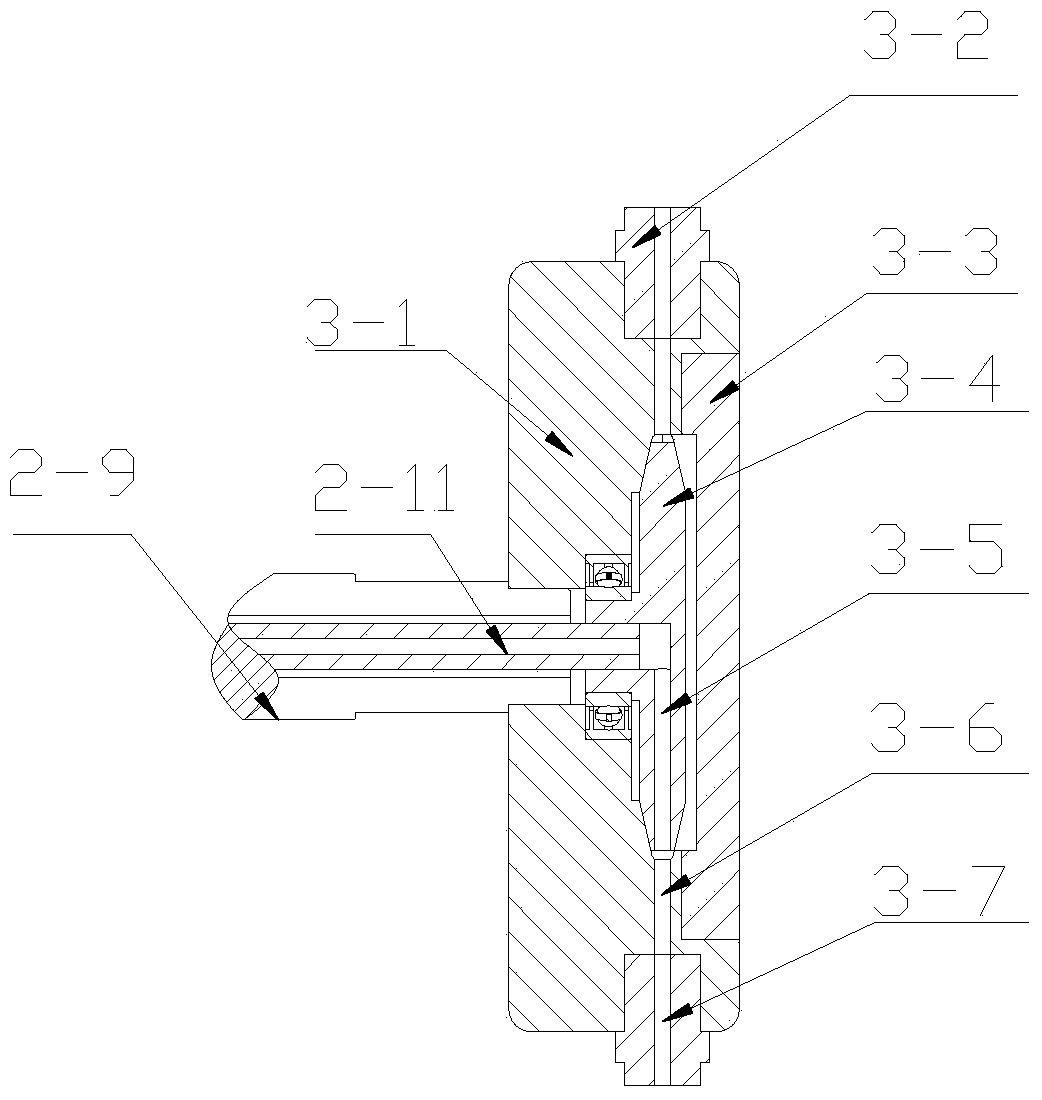

[0022] Embodiment 2 On the basis of Embodiment 1, preferably, the rotatable tool holder 3 includes a tool holder shell 3-1, a stud 3-2, a knife holder sealing cover 3-3 and a fixed oil storage pan 3 -4, the tool rest shell 3-1 is cylindrical, and along the central axis of the tool rest shell 3-1, a stepped hole and a first semi-closed cavity are sequentially arranged on the tool rest shell 3-1 Body, on the inner wall of the first semi-closed cavity body, a first oil passage 3-6 is provided along the radial direction of the tool holder shell 3-1, and a first oil passage 3-6 is provided on the tool holder sealing cover 3-3. Two semi-closed hollow bodies, the knife rest sealing cover 3-3 is detachably connected on the knife rest shell 3-1, after the knife rest sealing cover 3-3 is connected with the knife rest shell 3-1, the first The semi-closed cavity body and the second semi-closed cavity body form a closed cavity body, and the shape of the closed cavity body matches the shape...

Embodiment 3

[0023] Embodiment 3 On the basis of Embodiment 2, the fixed tool holder 2 further includes a fixed hollow shaft 2-10, and the fixed hollow shaft 2-10 runs through the center axis of the rotary hollow main shaft 2-9. In the rotary hollow main shaft 2-9, one end of the fixed hollow shaft 2-10 is fixedly mounted on the tool seat shell 2-11, and the other end is interference fit with the axial blind hole of the fixed oil storage tray 3-4, The fixed hollow shaft is used as an oil channel for oil delivery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com