Automatic storing and taking method for hob of shield tunneling machine

A technology of automatic access and shield machine, applied in the field of shield machine, can solve the problems of large physical strength, consumption, affecting the efficiency of tool change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the present invention more apparent, it is described in detail with reference to the accompanying drawings.

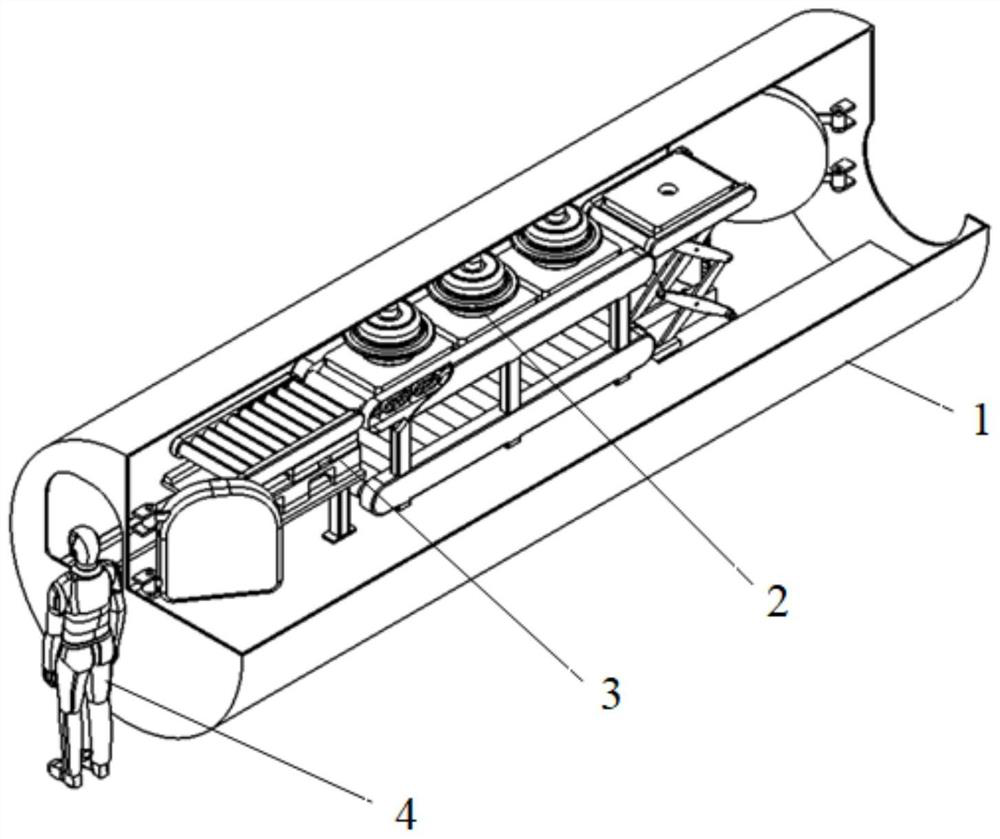

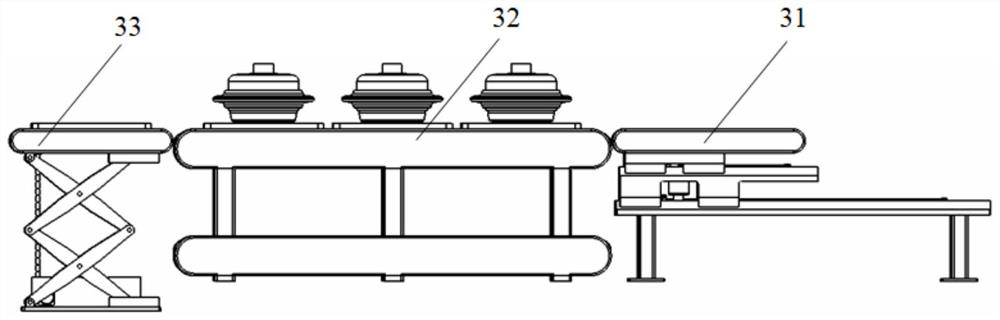

[0047] The present invention provides a shield mechanical hob access method, which requires an automatic roller holder, such as figure 1 As shown, the automatic roller holder includes a hatch 1 and an automatic tool holder 3. The automatic tool holder 3 is mounted inside the bodies 1, the bodies 1 are collorated, and the bodies 1 are connected to the shield machine body by screws.

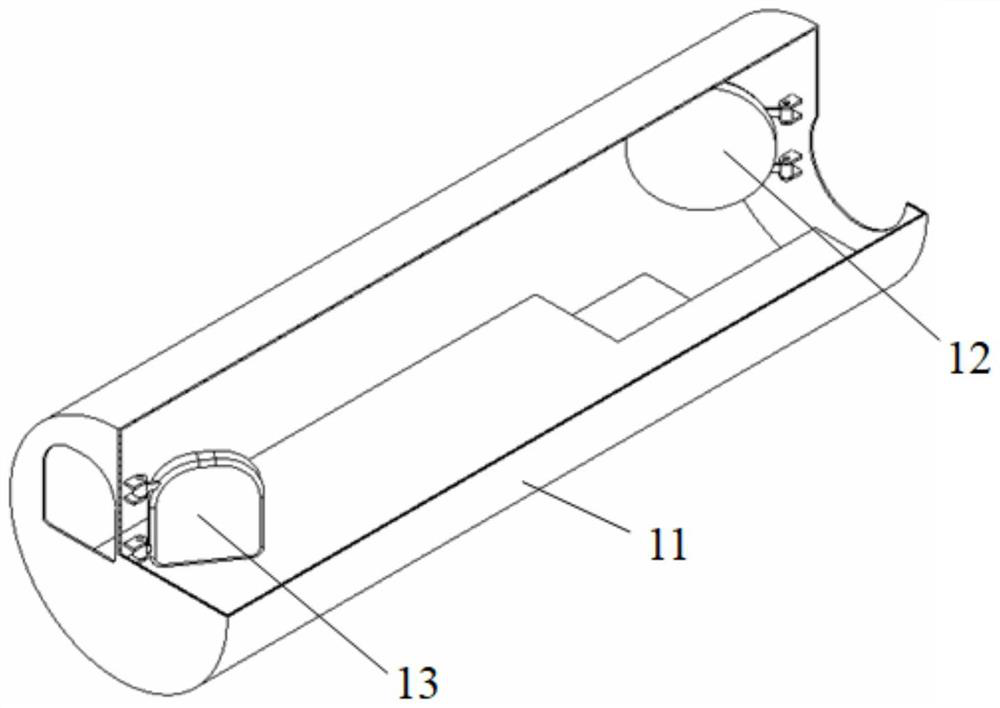

[0048] Such as figure 2 As shown, the bodies 1 are composed of housing 11, the front hat 12, and the rear hatch 13, the front hat 12 and the rear hatch 13 are provided on the housing 11, the front hatch 12 is close to the mud tank (or the cutter disc ), The rear hatch 13 is opposed to the front hatch 12, and the housing 11 is welded by a high strength steel sheet roller. Both the front hatch 12 and the rear hatch 13 are all open to the open state, when the chamber is req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com