Multifunctional tunnel arch erecting machine

A multi-functional, tunnel technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of large installation limitations of steel arches and affect the assembly efficiency and quality of steel arches, so as to improve installation efficiency and quality, Diversified functions and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

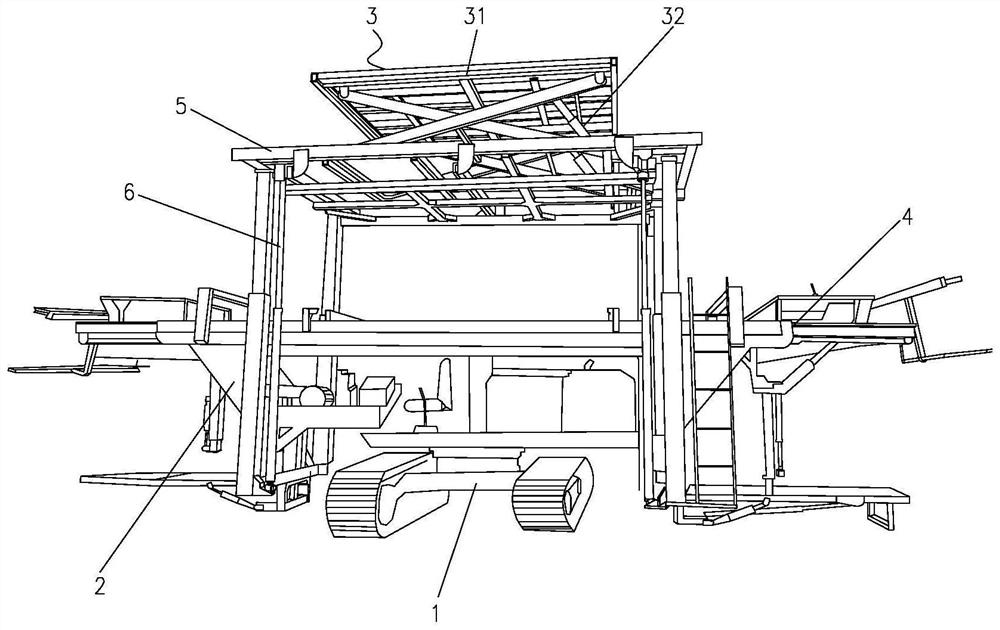

[0024] Such as Figure 1-3 As shown, the multifunctional tunnel erecting machine of the present invention includes a mobile trolley 1 (generally an engineering vehicle) and a support frame 2; the support frame 2 is fixedly connected to the mobile trolley 1, and the mobile trolley 1 drives the support frame 2 Multi-dimensional movement (the mobile trolley 1 is used to drive the support frame 2 into and out of the tunnel, and at the same time it can move left and right in the tunnel to adjust to the best position to install the arch frame); the support frame 2 is equipped with at least two for clamping and fixing The arch clamping assembly of the arch segment, the arch clamping assembly drives the arch segment on it to expand and contract in the radial direction of the tunnel cross section.

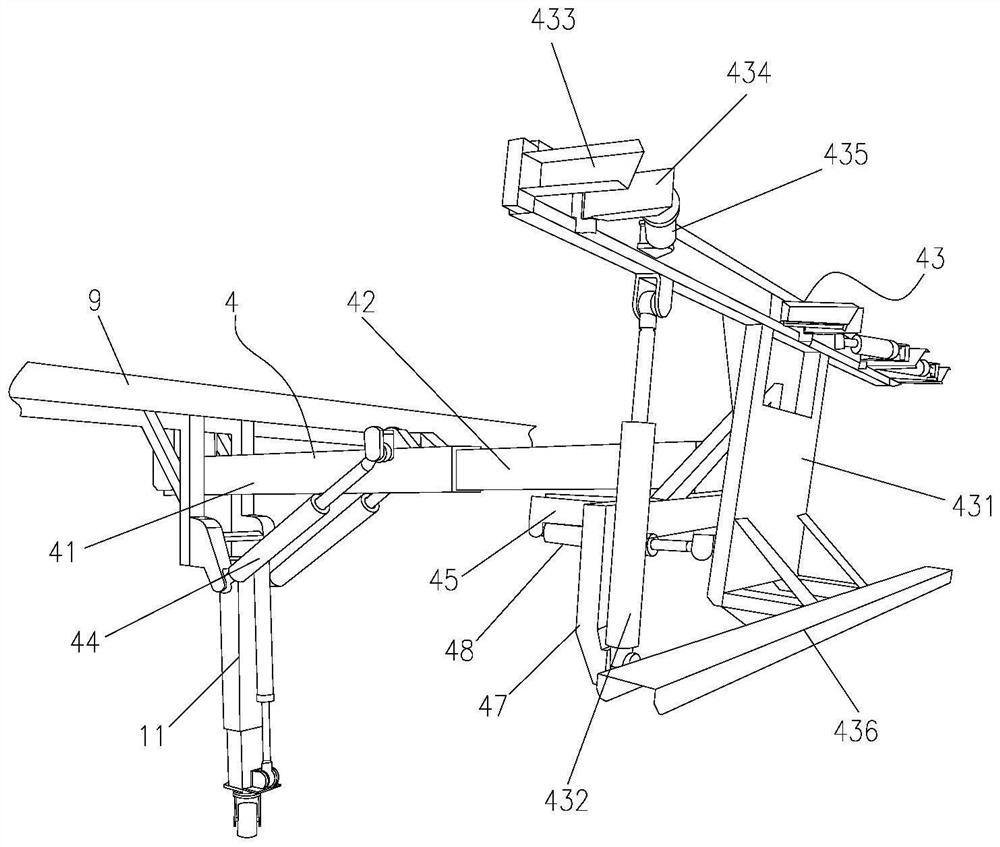

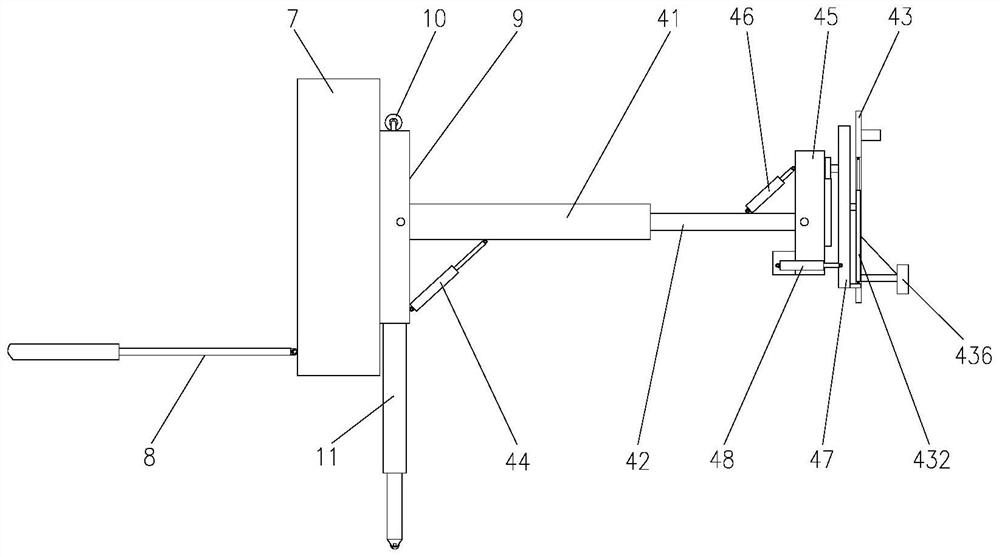

[0025] Preferably, in this embodiment, the arch clamping assembly includes a vertical arch clamping assembly 3 and two lateral arch clamping assemblies 4, the vertical arch clamping assembl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap