Fixed-point track line matching method

A track line, fixed-point technology, applied in the field of collar, can solve the problems of uneven collar seat, difficult to grasp, complicated lapel angle, etc., to achieve beautiful lines and outlines, accurate operability, obvious advancement and rationality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

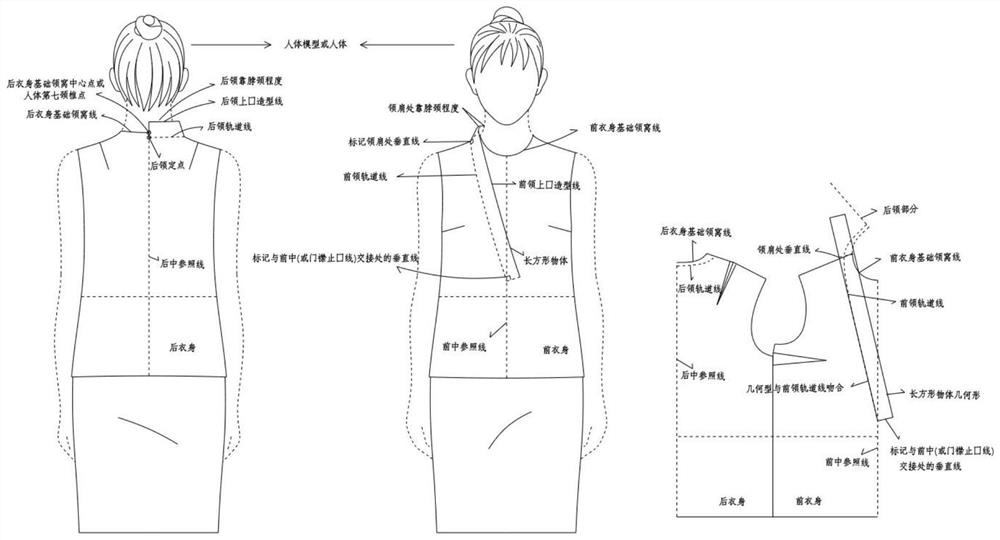

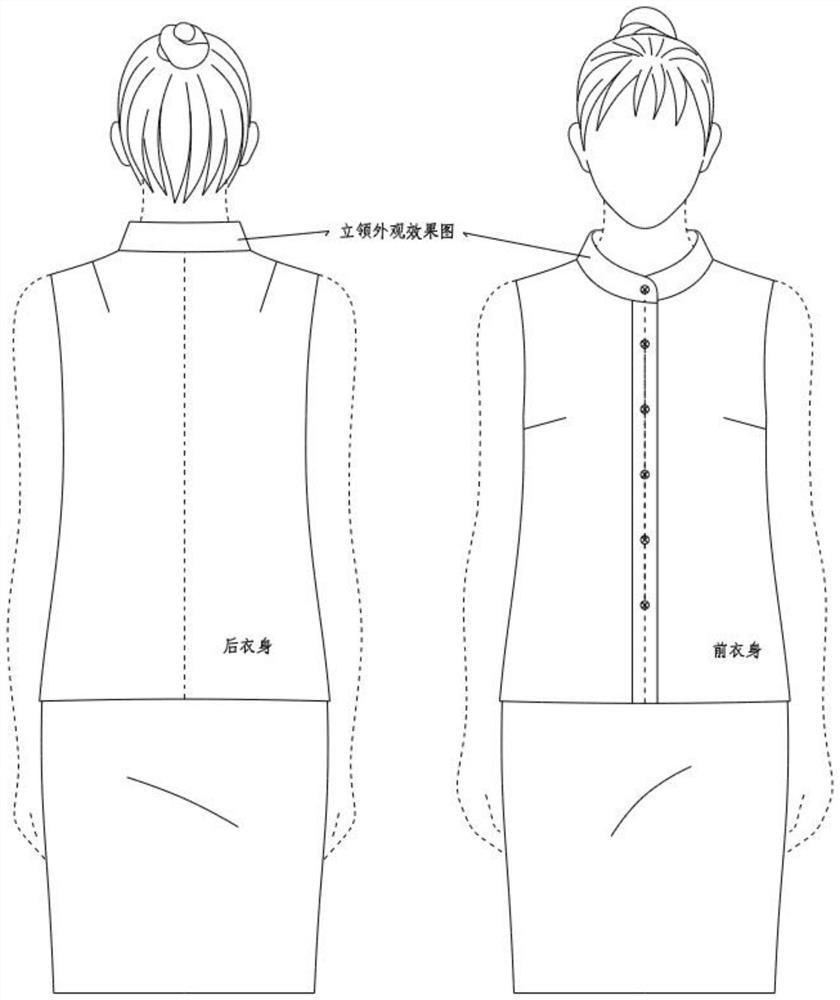

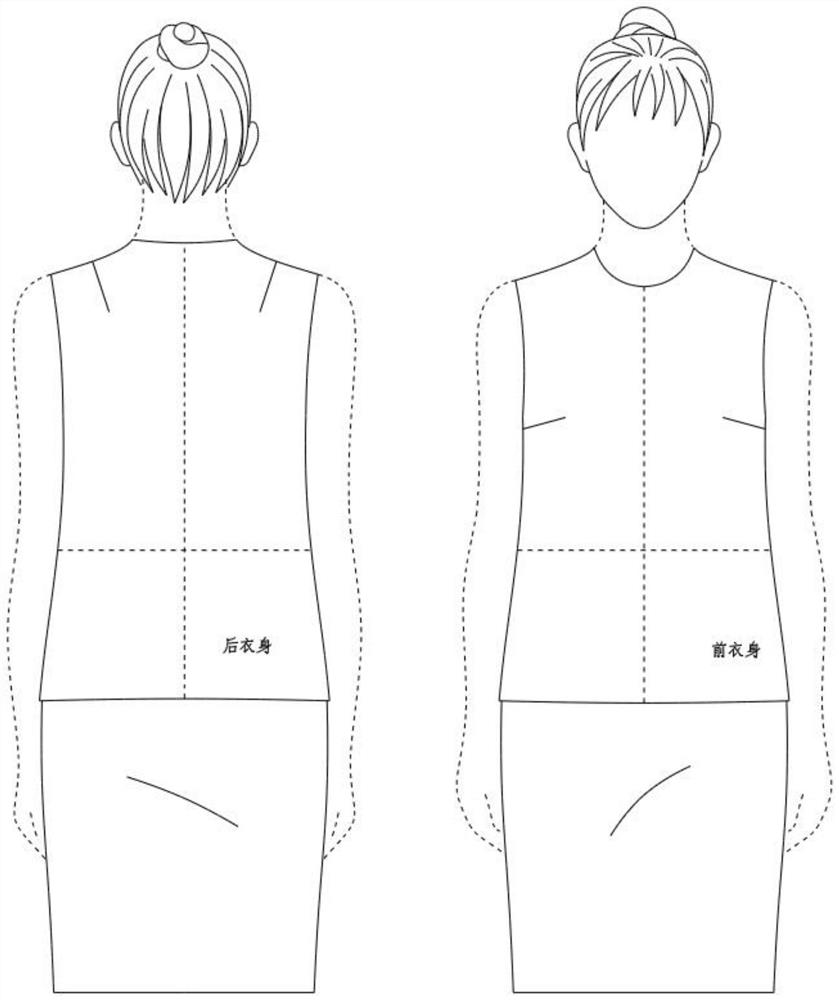

[0049] refer to Figure 1-Figure 8 , when the fixed-point track line matching method of the present invention is used for standing collar matching, it comprises the following steps:

[0050] Step S1, see figure 2 According to the requirements of the stand-up collar design, the stand-up collar width of the collar is 3.5CM, the collar length is 43CM, and the distance between the collar and the neck is determined in advance. . The present embodiment stand-up collar is the symmetrical formula stand-up collar of left and right symmetry, so only need make half side.

[0051] Step S2, see Figure 4 , according to the design requirements of the stand-up collar, take a rectangular object. The length of the rectangular object is equal to half of the length required for one week of the stand collar design, which is 21.5CM. The width of the rectangular object is equal to the height 3.5CM of the stand collar design. Present embodiment is symmetrical collar, only needs to make half s...

Embodiment 2

[0059] refer to Figure 9-Figure 14 , when the fixed-point track line matching method of the present invention is used for lapel matching, it comprises the following steps:

[0060] Step S1, see Figure 9 , Figure 10 , according to the design requirements of the lapel, pre-determine the collar seat height of 3.5CM, the collar length of 81CM and the distance between the collar and the neck. In this embodiment, the lapel is a symmetrical stand collar with left and right symmetry.

[0061] So just make half sides.

[0062] Step S2, see Figure 10 , according to the lapel shape design requirements, take a rectangular object. The length of the rectangular object is equal to half of the required length of the design of the lapel, which is 40.5CM. The width of the rectangular object is equal to the height 3.5CM of the lapel design. Present embodiment is symmetrical collar, only needs to make half side and gets final product, so the length of rectangular object can get half of...

Embodiment 3

[0070] refer to Figure 14-Figure 19 , when the fixed-point track line matching method of the present invention is used for asymmetrical collar matching, it comprises the following steps:

[0071] Step S1, see Figure 15 , according to the asymmetrical collar matching design requirements, pre-determine the collar seat height of 3.5CM, collar length 61CM and the distance between the collar and the neck. 0.8CM. In this embodiment, the left and right collars are asymmetrical, so a complete collar needs to be made. In the present embodiment, the collar shape requires that the length of the lapel shape is 40.5CM on the front right side, and the length of the stand collar shape on the left side is 20.5CM.

[0072] Step S2, see Figure 16 , according to the lapel shape design requirements, take a rectangular object. The length of the rectangular object is equal to 61CM of the required length of the design of the lapel for one week. The width of the rectangular object is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com