Strip load temperature measurement method for air cushion type continuous heat treatment line

A technology of air cushion type and strip material, which is applied in the direction of thermometers, thermometers, and measuring devices using electric/magnetic elements that are directly sensitive to heat. less time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

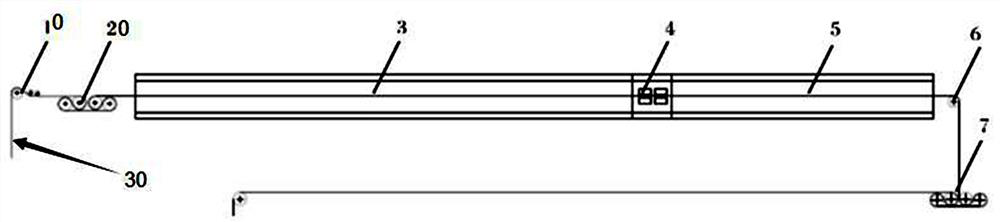

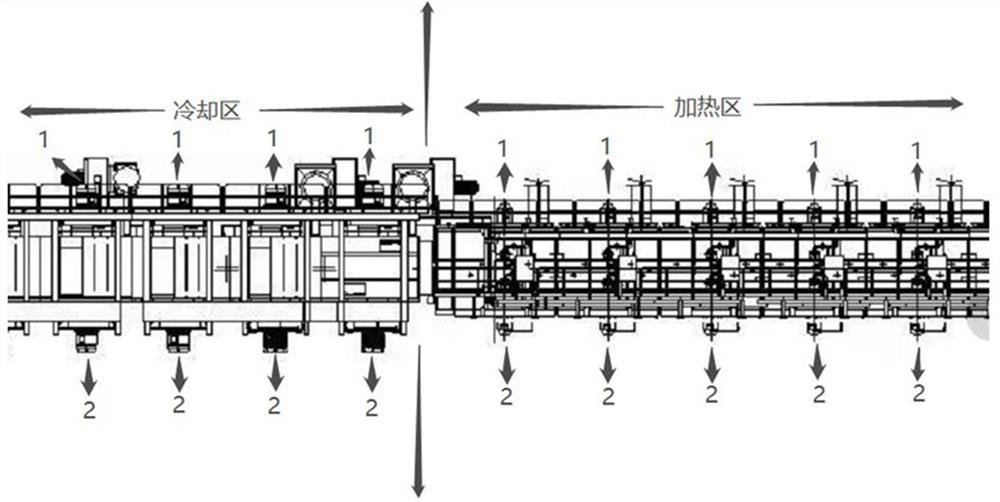

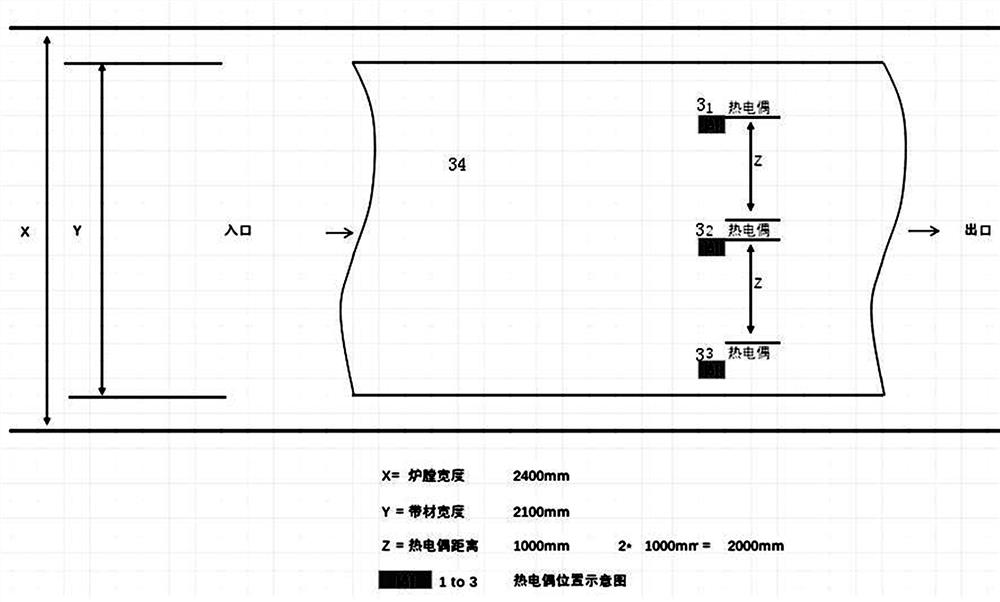

[0066] Before temperature measurement, raise the temperature of the furnace gas in the air-cushion continuous heat treatment line to the set temperature of 500°C and keep it warm for 2 hours; use a drill to drill a hole in the strip at the entrance of the air-cushion continuous heat treatment line. image 3 Arrange the temperature-measuring thermocouples in the manner shown. Use rivets to fix the thermocouple on the strip to prevent the thermocouple from falling off when the temperature measurement strip moves. Connect the other end of the thermocouple to the signal input port of the paperless recorder to receive the temperature measurement signal data of the thermocouple in real time.

[0067] After the thermocouple is fixed, the strip temperature test starts at the preset production speed, and the preset speed is controlled at 24m / min; during the test, the air-cushion continuous heat treatment line speeds up to the set speed at one time. After the strip runs for 3 minutes, ...

Embodiment 2

[0070] Before temperature measurement, raise the temperature of the furnace gas in the air-cushion continuous heat treatment line to the set temperature of 470°C and keep it warm for 1.5 hours; Figure 4 Arrange the temperature-measuring thermocouples in the manner shown. Use rivets to fix the thermocouple on the strip to prevent the thermocouple from falling off when the temperature measurement strip moves. Connect the other end of the thermocouple to the signal input port of the paperless recorder to receive the temperature measurement signal data of the thermocouple in real time.

[0071] After the thermocouple is fixed, the strip temperature test starts at the preset production speed, and the preset speed is controlled at 18m / min; during the test, the air-cushion continuous heat treatment line speeds up to the set speed at one time. After the strip runs for 4 minutes, the temperature measuring thermocouple enters the cooling section, and the remaining thermocouple extensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com