Pipeline crack visual detection method and system based on three-dimensional induction eddy current magnetic field cloud picture

A technology of inductive eddy current and detection method, which is applied to measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of large detection error, inability to achieve accurate evaluation and effective identification of surface defects of materials, and achieve improved accurate evaluation, Realize the effect of intuitive visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

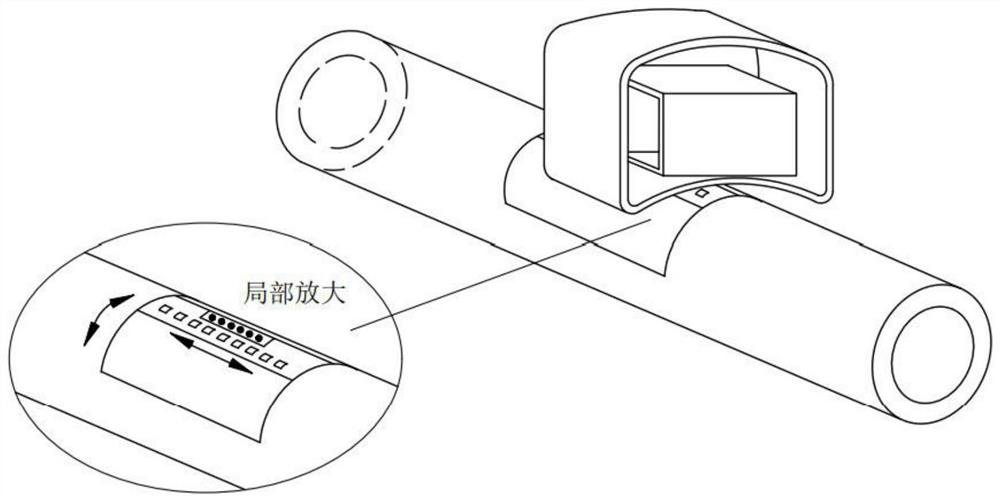

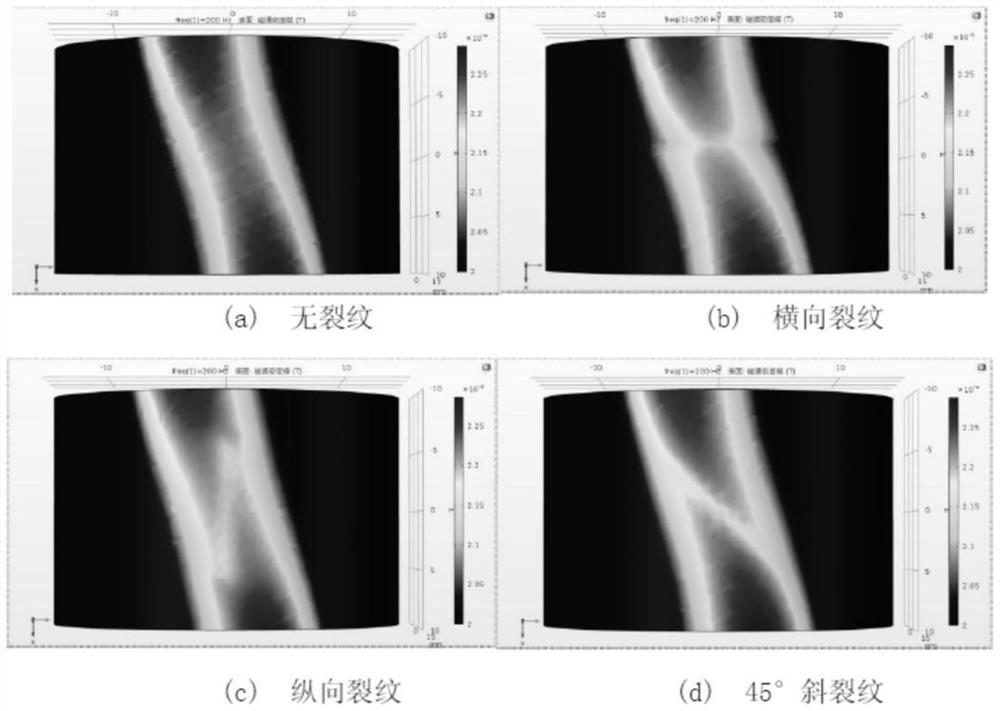

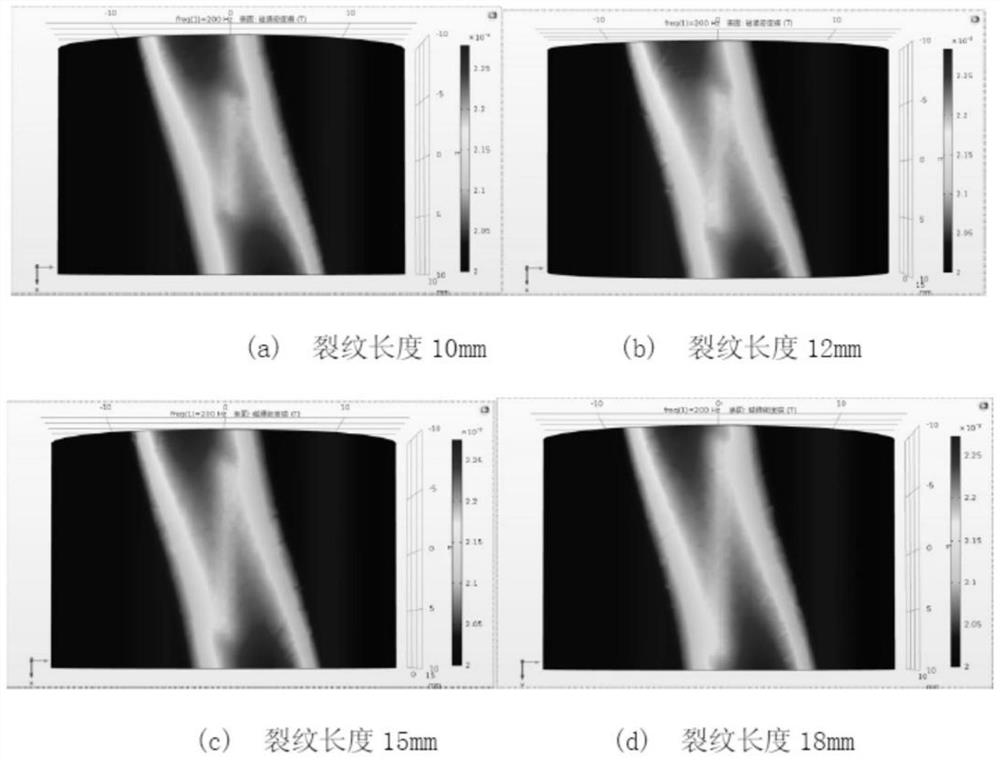

[0022] see Figure 1 to Figure 5 , the present embodiment provides a method and system for visual detection of pipeline cracks based on three-dimensional induced eddy current magnetic field nephogram. In the implementation process, a double-coil non-contact detection probe is placed above the metal pipe to generate the excitation signal of the eddy current magnetic field and measure the change of the magnetic field on the surface of the measured object. figure 1 Shown is the schematic diagram of the structure of the probe, which consists of two excitation coils, detection sensors and metal pipes to be detected. The outer coil of the probe is an arc coil coaxial with the pipeline, and the inner coil is a rectangular coil. The upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com