Water chilling unit digital twin model construction method and device, terminal and storage medium

A technology for chillers and construction methods, which is applied in the directions of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the problems of poor synchronization between virtual and real chillers and low fidelity of digital models, so as to achieve a consistent synchronization between virtual and real. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

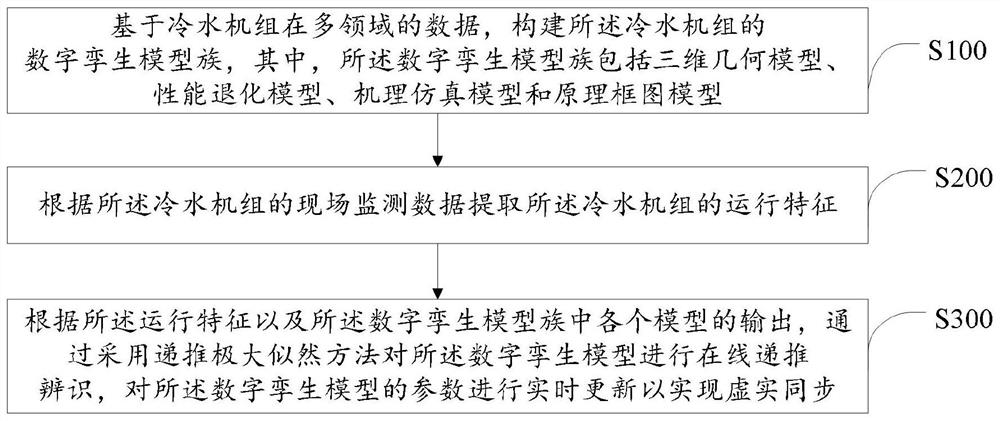

[0068] Such as figure 1 As shown, in an embodiment of the digital twin model construction method of the chiller, the steps are:

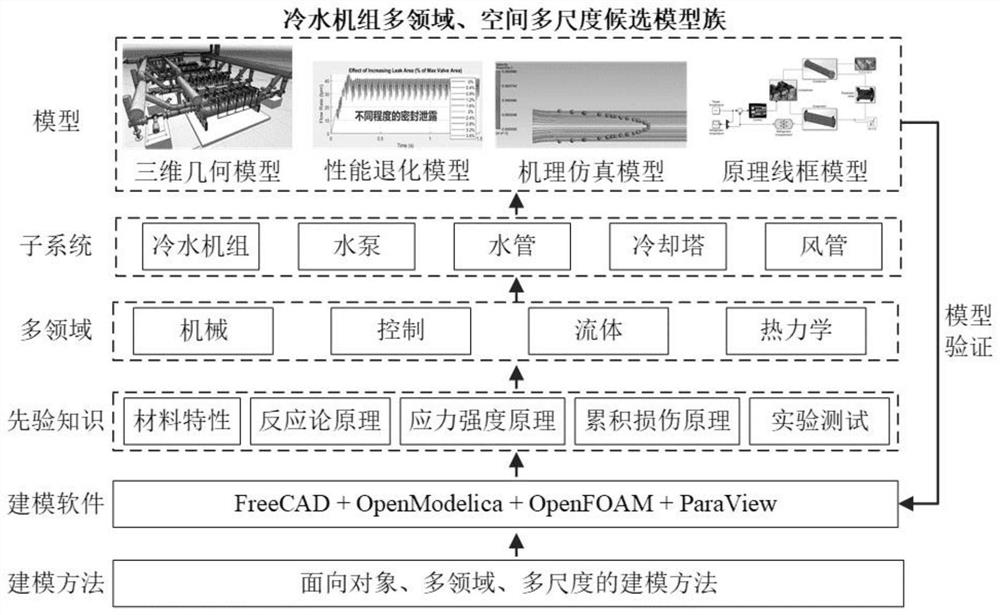

[0069] S100. Construct a digital twin model family of the chiller based on multi-field data of the chiller, wherein the digital twin model family includes a three-dimensional geometric model, a performance degradation model, a mechanism simulation model, and a functional block diagram model.

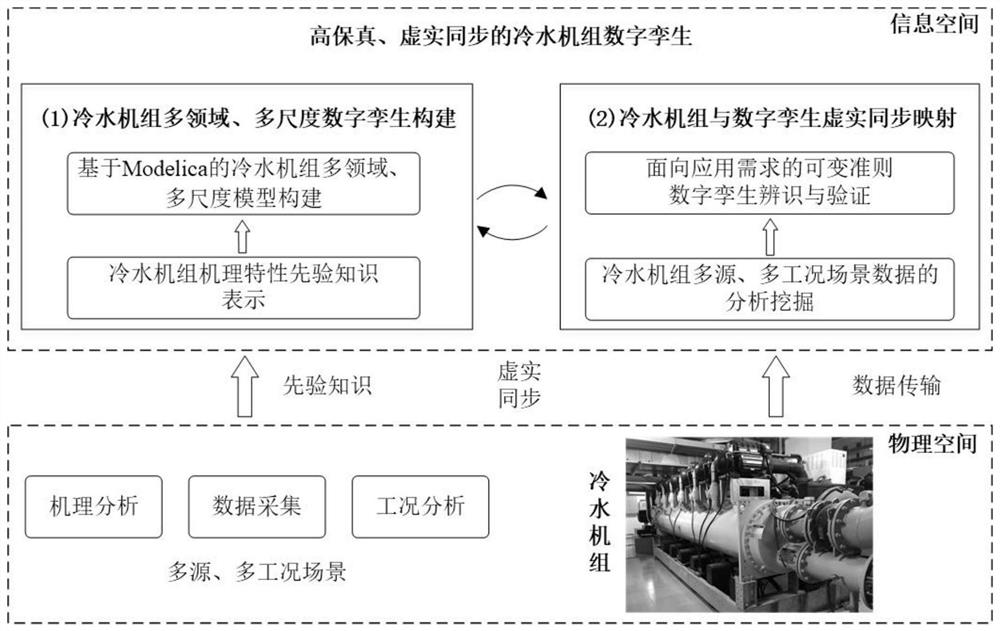

[0070] Specifically, the multi-field data of the chiller includes data in the mechanical, control, fluid, and thermodynamic fields of the chiller, including actual operating data, empirical formulas, and empirical parameters. In this embodiment, multiple models are constructed according to the data of the chiller in multiple fields. Such as figure 2 As shown, first construct a model based on the prior knowledge of the chiller, then identify the constructed model based on the actual operating data of the chiller, and update the parameters of the model so tha...

Embodiment 2

[0150] Based on the above embodiments, the present invention also provides a corresponding digital twin model building device for chillers, such as Figure 10 As shown, the device includes:

[0151] A model building module, the model building module is used to construct the digital twin model family of the chiller based on the multi-field data of the chiller, wherein the digital twin model family includes a three-dimensional geometric model, a performance degradation model, and a mechanism A simulation model and a schematic block diagram model, specifically as described in Embodiment 1;

[0152] A feature extraction module, the feature extraction module is used to extract the operating characteristics of the chiller according to the monitoring data of the chiller, specifically as described in Embodiment 1;

[0153] A virtual-real synchronization module, the virtual-real synchronization module is used to identify the models in the digital twin model family by using the recursi...

Embodiment 3

[0155] Based on the above embodiments, the present invention also provides a corresponding terminal, such as Figure 11 As shown, the terminal includes a processor 10 and a memory 20 . Figure 11 Only some components of the terminal are shown, but it should be understood that implementation of all illustrated components is not required, and more or fewer components may be implemented instead.

[0156] The storage 20 may be an internal storage unit of the terminal in some embodiments, such as a hard disk or memory of the terminal. In other embodiments, the memory 20 may also be an external storage device of the terminal, such as a plug-in hard disk equipped on the terminal, a smart memory card (Smart Media Card, SMC), a secure digital (Secure Digital, SD ) card, flash memory card (Flash Card), etc. Further, the memory 20 may also include both an internal storage unit of the terminal and an external storage device. The memory 20 is used to store application software and vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com