Medical adhesive tape gluing machine capable of controlling constant adhesive force

A technology of adhesive force and gluing machine, which is applied in the field of gluing machines, can solve problems such as the inability to detect the adhesive force of medical tapes, differences in adhesive force, and affecting the normal use of medical tapes, so as to avoid snapping, inability to move, gluing Precise effect of stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

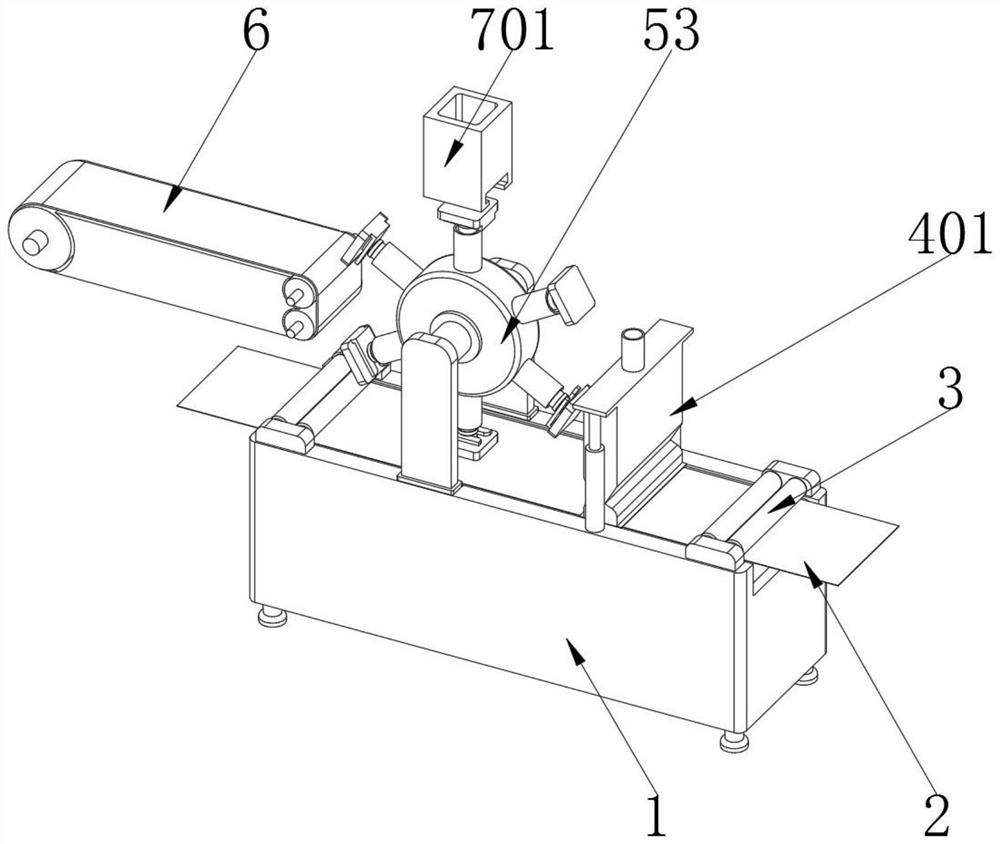

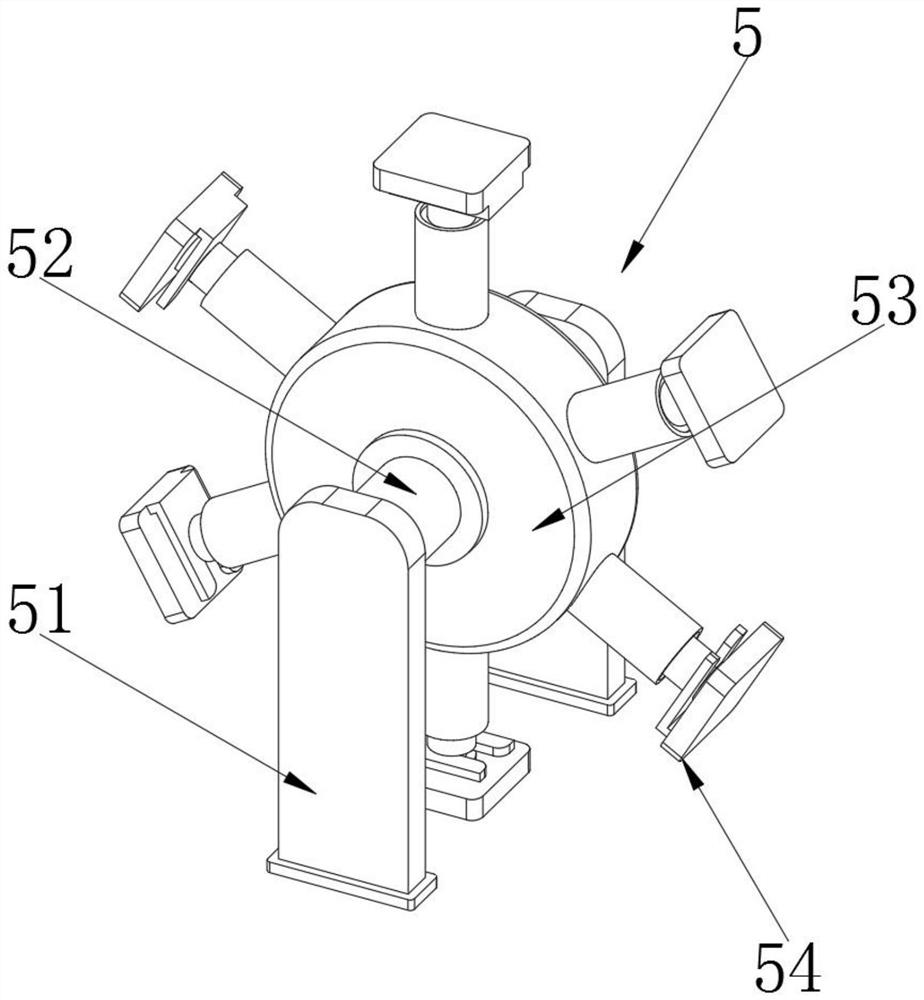

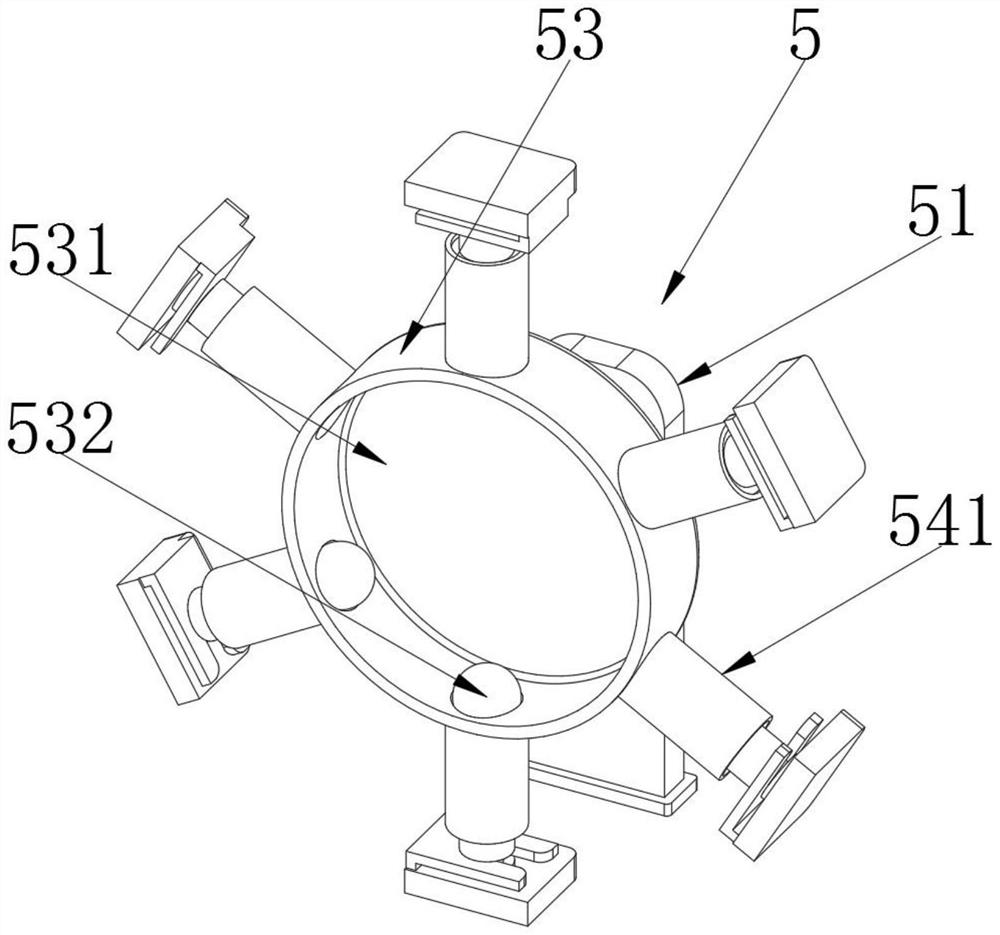

[0048] Example: such as Figure 1 to Figure 13 As shown, the present invention provides the following technical solutions, which can control a medical tape glue applicator with constant adhesive force. The two ends of the conveying table 1 limit the medical tape 2 by pressing the limit roller 3, so as to avoid the medical tape 2 from arching during the process of conveying and gluing, which affects the normal gluing and adhesive force detection. The gluing conveying table 1 Glue-applying mechanism 4 is arranged on it, and glue-applying mechanism 4 is used for carrying out glue-coating process to the conveyed medical adhesive tape 2, and the side of glue-applying mechanism 4 is provided with adhesive force detection mechanism 5, and adhesive force detection mechanism 5 is used for coating After gluing, the adhesive force on the surface of the medical tape 2 is detected to ensure that the adhesive force on the surface of the medical adhesive tape 2 is constant. The side of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com