Photovoltaic cell piece surface defect detection method and device and storage medium

A photovoltaic cell and defect detection technology, which is used in optical testing of flaws/defects, measuring devices, and material analysis by optical means to achieve clear imaging results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the accompanying drawings of the present invention are all in a simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

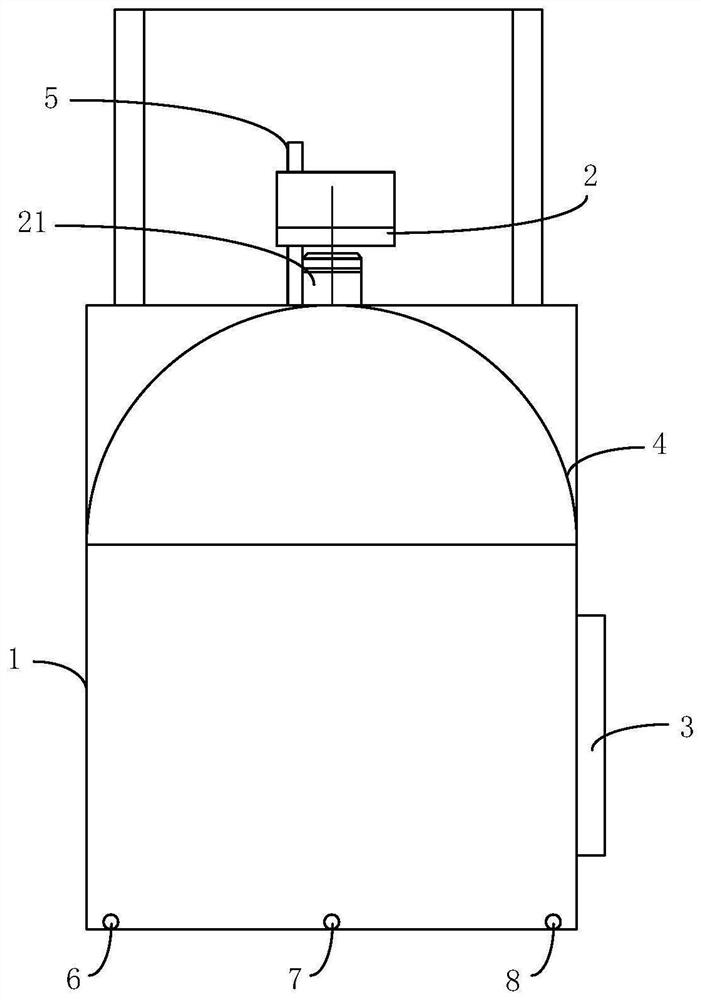

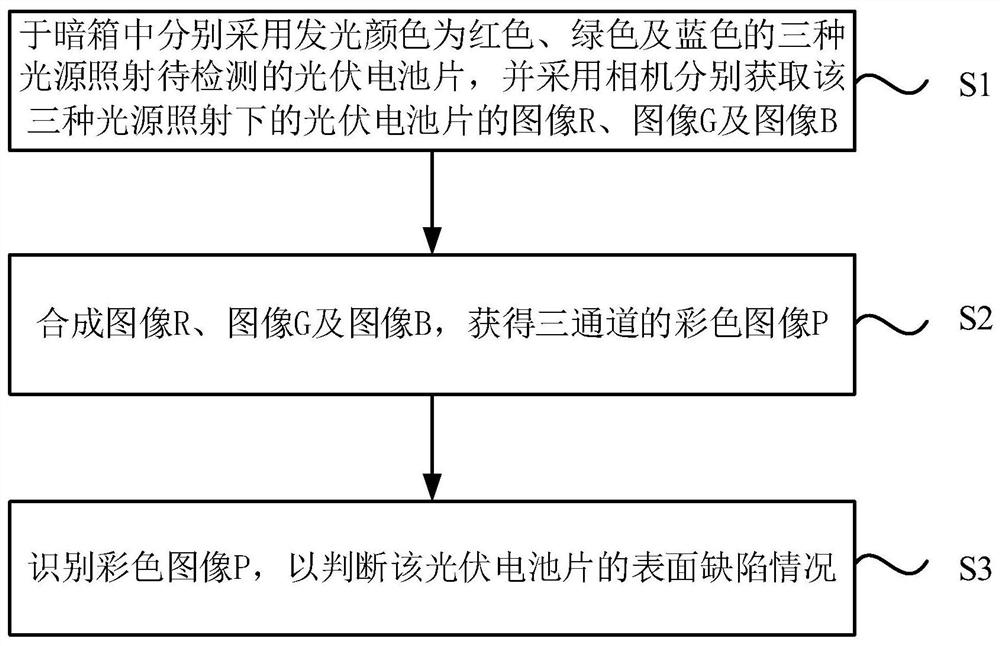

[0036] see figure 1 and figure 2 , figure 1 A schematic structural diagram of a photovoltaic cell surface defect detection device provided in an embodiment of the present invention, the device can be specifically based on figure 2 The method for detecting surface defects of photovoltaic cells shown in the flow chart is implemented to quickly and accurately detect defects of photovoltaic cells.

[0037] Specifically, as figure 1 As shown, the photovoltaic cell surface defect detectio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap