Lens driving device and image pickup device

A technology of lens driving device and lens barrel, which is applied in the field of focus motors, can solve the problems of multiple guide posts not being parallel, stop of focus movement, and focus movement jamming, etc., and achieve the effects of smooth focus movement, increased push weight, and improved focus stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The Z axis in this embodiment is the focusing optical axis.

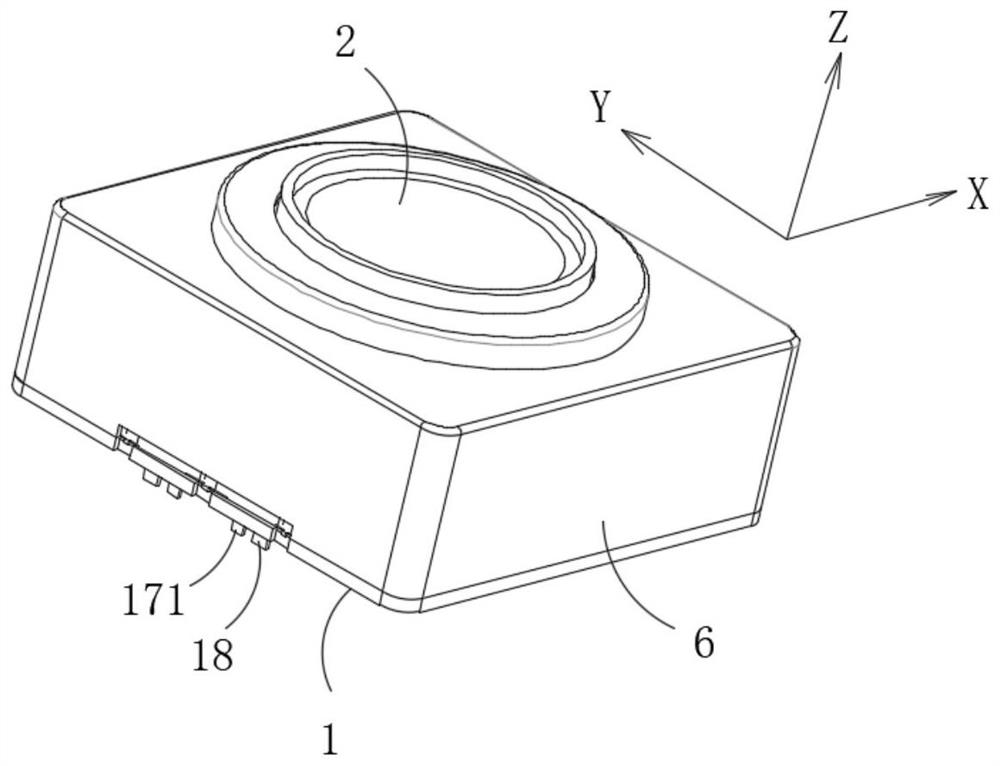

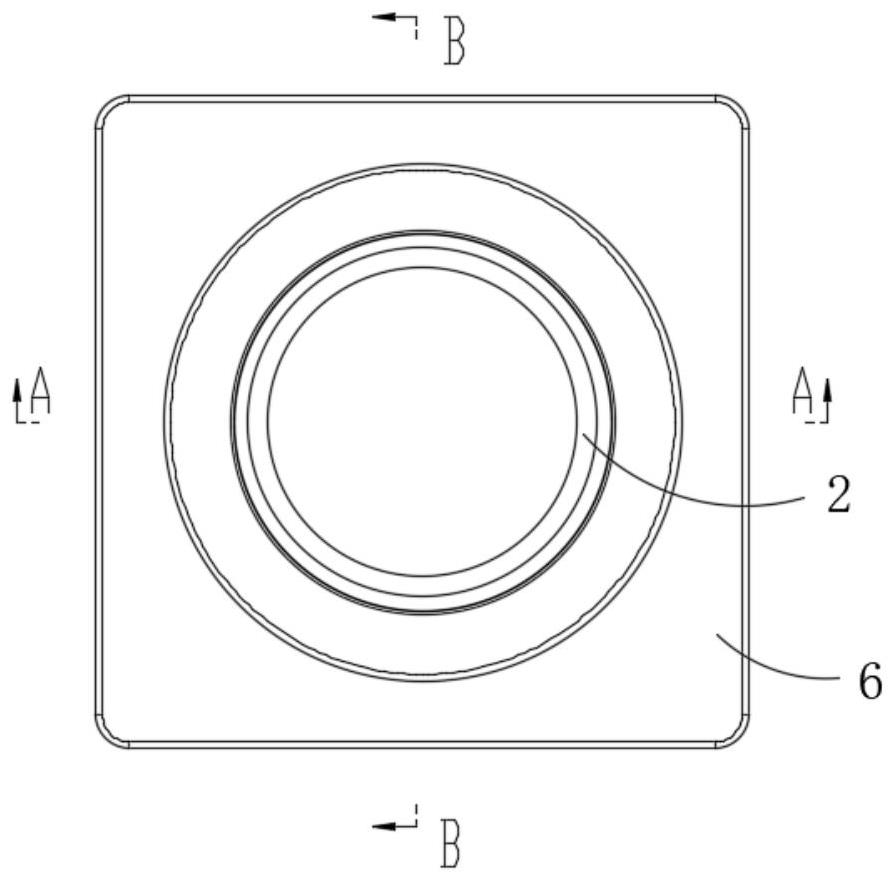

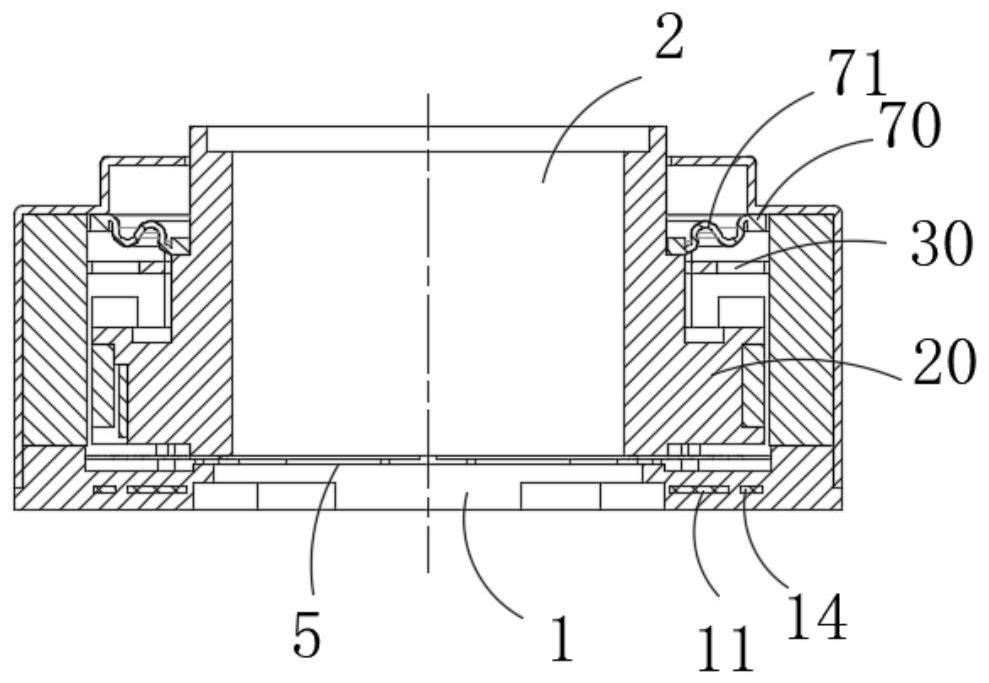

[0052] Such as Figure 1-Figure 4As shown, the lens driving device of this embodiment includes a base 1 , a telescopic lens barrel 2 , a guide post support 30 , a guide post 31 , an adaptive guide post elastic clip 32 , an electromagnetic drive mechanism 4 , a housing 6 and a waterproof gasket 7 .

[0053] Such as Figure 5-Figure 6 As shown, the four corners of the base 1 have corner columns 10 respectively, and the corner columns 10 are used to limit the position of the shell 6 fastened on the base 1 to achieve precise fastening of the shell 6 .

[0054] Preferably, a step is formed between the two exterior surfaces of the corner column 10 and the base 1. When fastened, the inner wall of the housing 6 conforms to the two exterior surfaces. After being installed in place, the housing 6 is installed at the stepped position.

[0055] Telescopic lens barrel 2 is used for carrying lens; Figure 7 As shown, th...

Embodiment 2

[0101] Based on Example 1, such as Figure 12 As shown, this embodiment provides an imaging device having the lens driving device described in Embodiment 1. The lens driving device carries a lens. Camera devices such as mobile phones and electronic tablets and other electronic equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com