Manufacturing method of NOR flash memory device

A flash memory device and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem that the thickness of the side wall is not easy to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be described below with reference to the accompanying drawings.

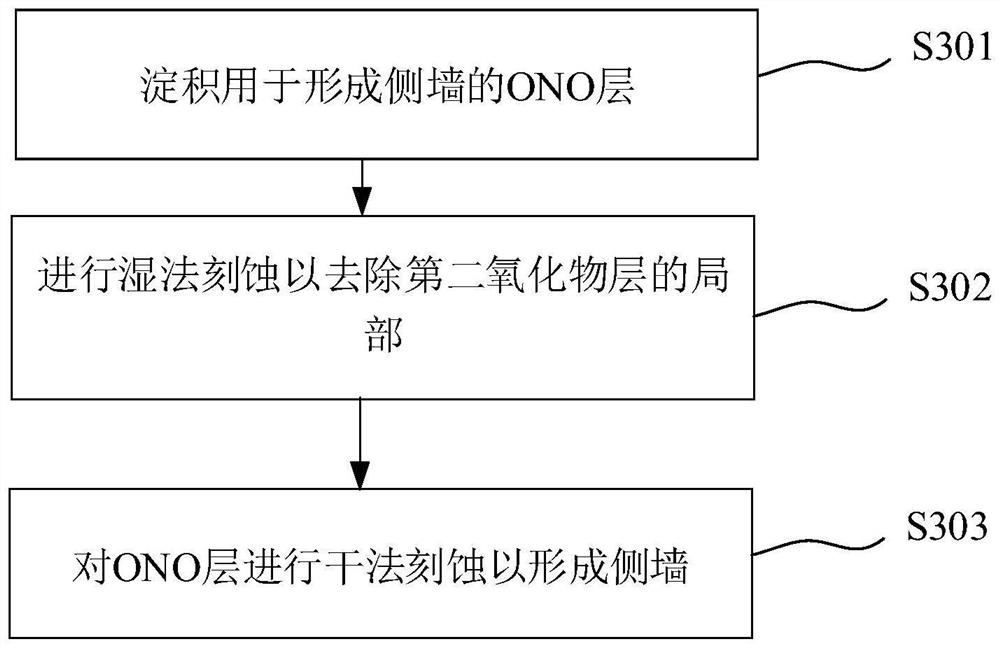

[0031] This embodiment provides a method of fabricating one or non-flash memory device. Refer figure 2 The method of making the or non-flash memory device includes the following steps:

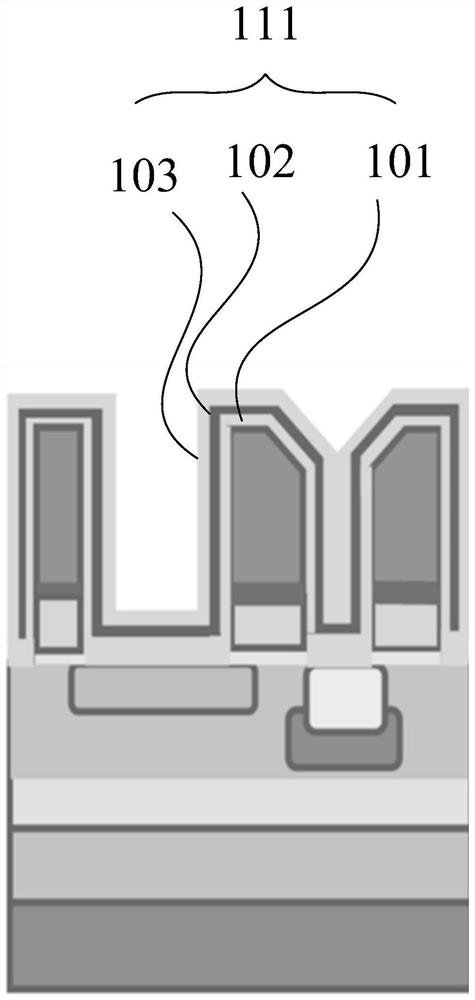

[0032] Step S301 is deposited to form an ONO layer of the side wall. The ONO layer includes a first oxide layer 101, a nitride layer 102, and a second oxide layer 103.

[0033] Step S302, wet etching to remove part of the second oxide layer.

[0034] Step S303, the ONO layer is carried out to form a side wall.

[0035] Then, other structures forming the or non-flash memory device, for example, the source drain ion implantation is performed on the storage unit area, and the source canal ion implantation is performed.

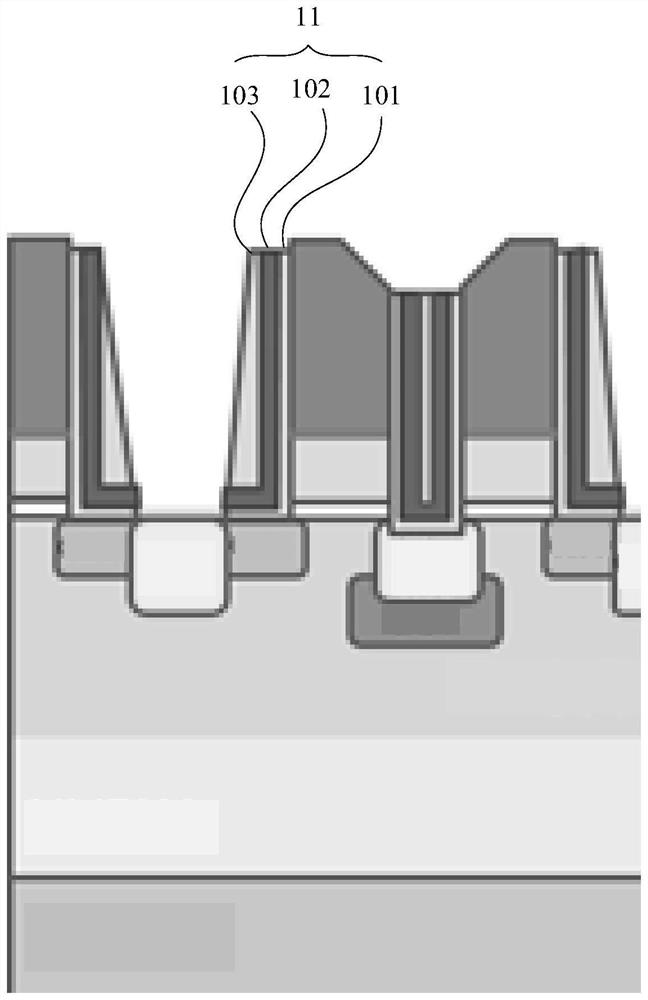

[0036] In the specific implementation, first, according to step S301, reference image 3 The first oxide layer 101, the nitride layer 102, and the second oxide layer 103 are formed, thereby for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com