Thin support structure for rotary regenerative heat exchanger

A technology for regenerative heat exchangers and support structures, applied in the direction of heat exchanger types, heat exchange equipment, regenerative heat exchangers, etc., to solve problems such as space limitations for adding and removing adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

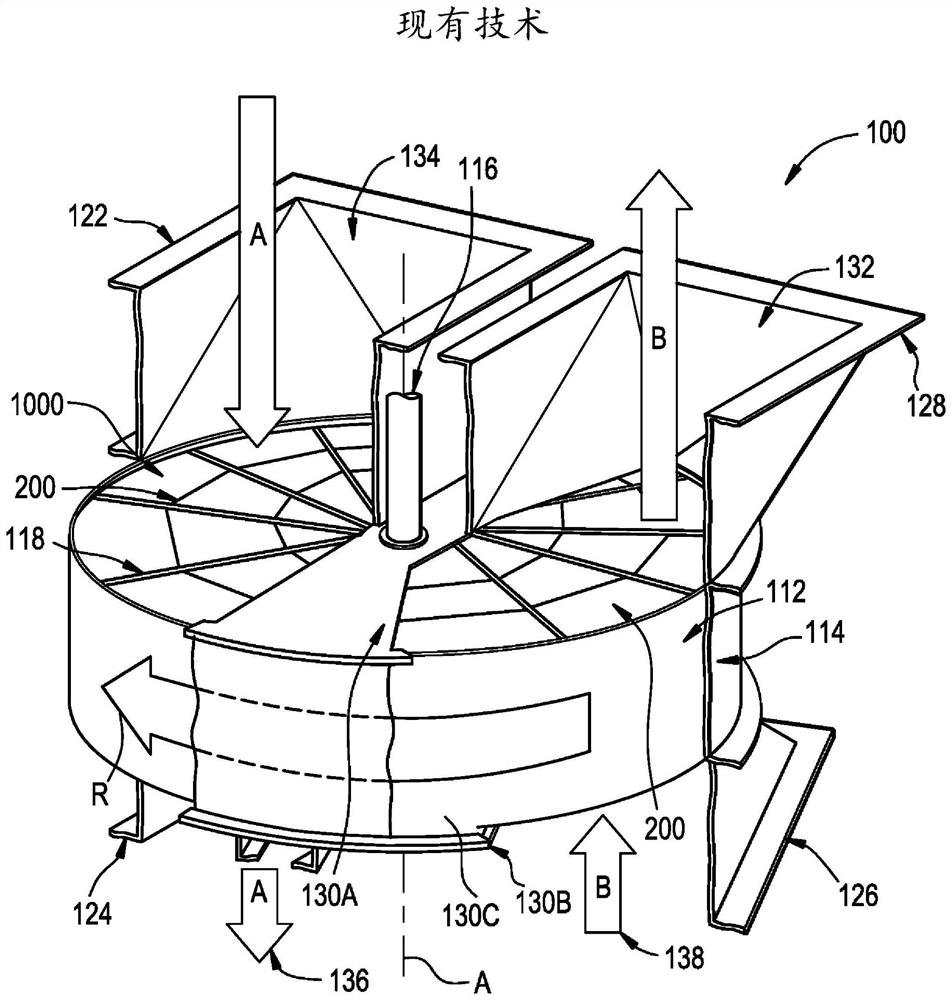

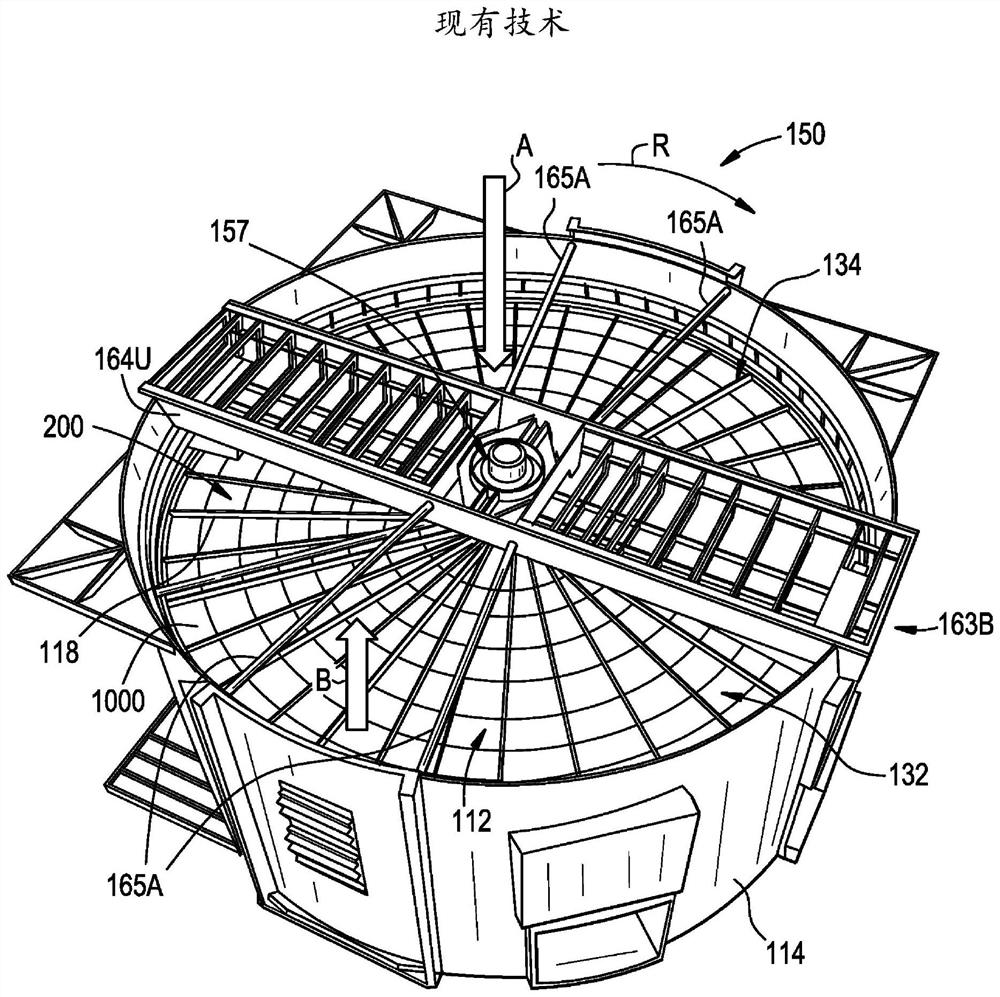

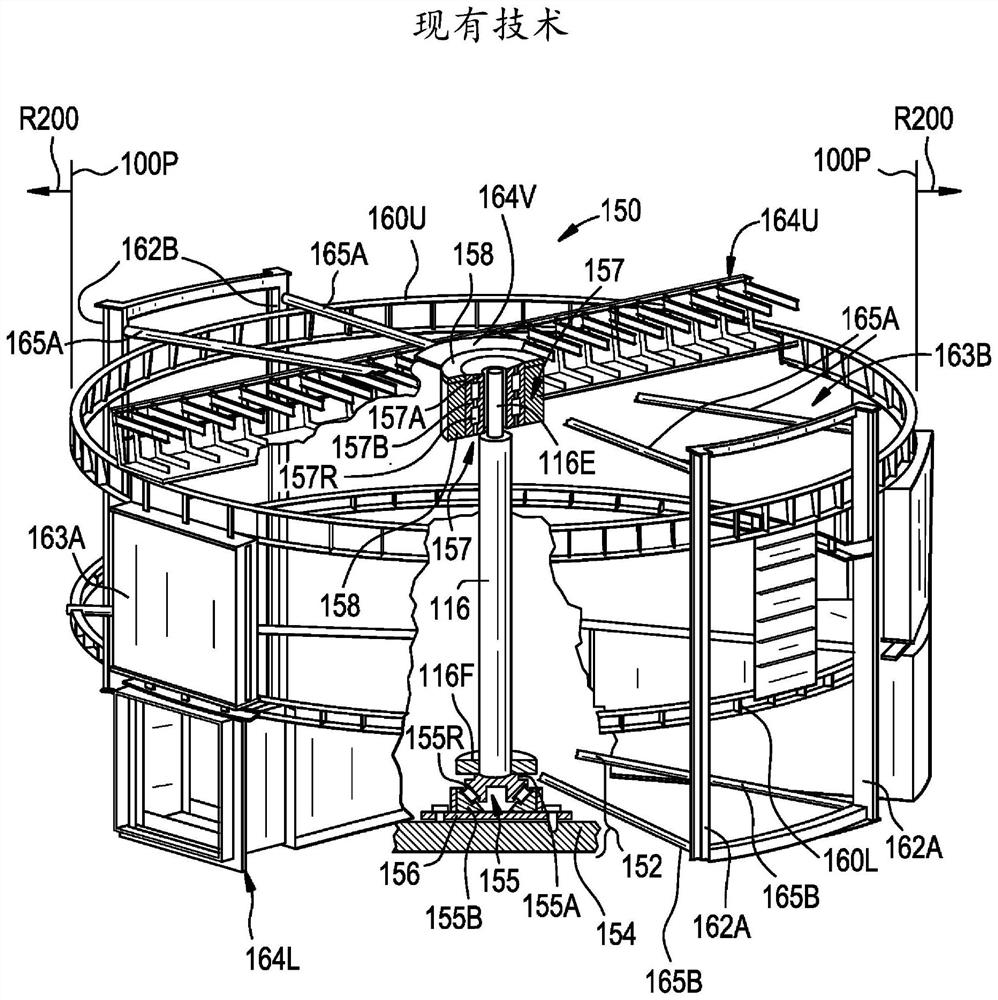

[0047] Such as Figure 4A As shown, the rotating regenerative heat exchanger 1 (see Figure 5A ) supporting structures are usually designated by the number 10. The support structure 10 is used to accommodate the rotor assembly 90 of the rotating regenerative heat exchanger 1 (see Figure 5A ) and for structural support and installation to foundations and piping ( Figure 12 piping system shown) of the exoskeleton. The support structure 10 is composed of an upper section 10U and a lower section 10L, which are axially spaced apart from each other along the central axis A and concentric with the central axis A, so that in the upper section 10U and the lower section An annular space S1 is defined between the segments 10L. Annular space S1 is configured to receive compartment 92 of rotor assembly 90, as referenced herein Figure 5A mentioned.

[0048] Such as Figure 4A As shown, the central axis A represents the vertical direction and thus the terms upper and lower are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com